Manufacturing process of coarse grained thenardite

Anhydrous Glauber's Salt, a manufacturing process technology, applied in the direction of inorganic chemistry, alkali metal sulfite/sulfite, alkali metal compounds, etc., can solve the problems of shortened production process, excessive storage equipment, etc., to reduce dredging Waiting for work, shortening the process flow, and benefiting the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

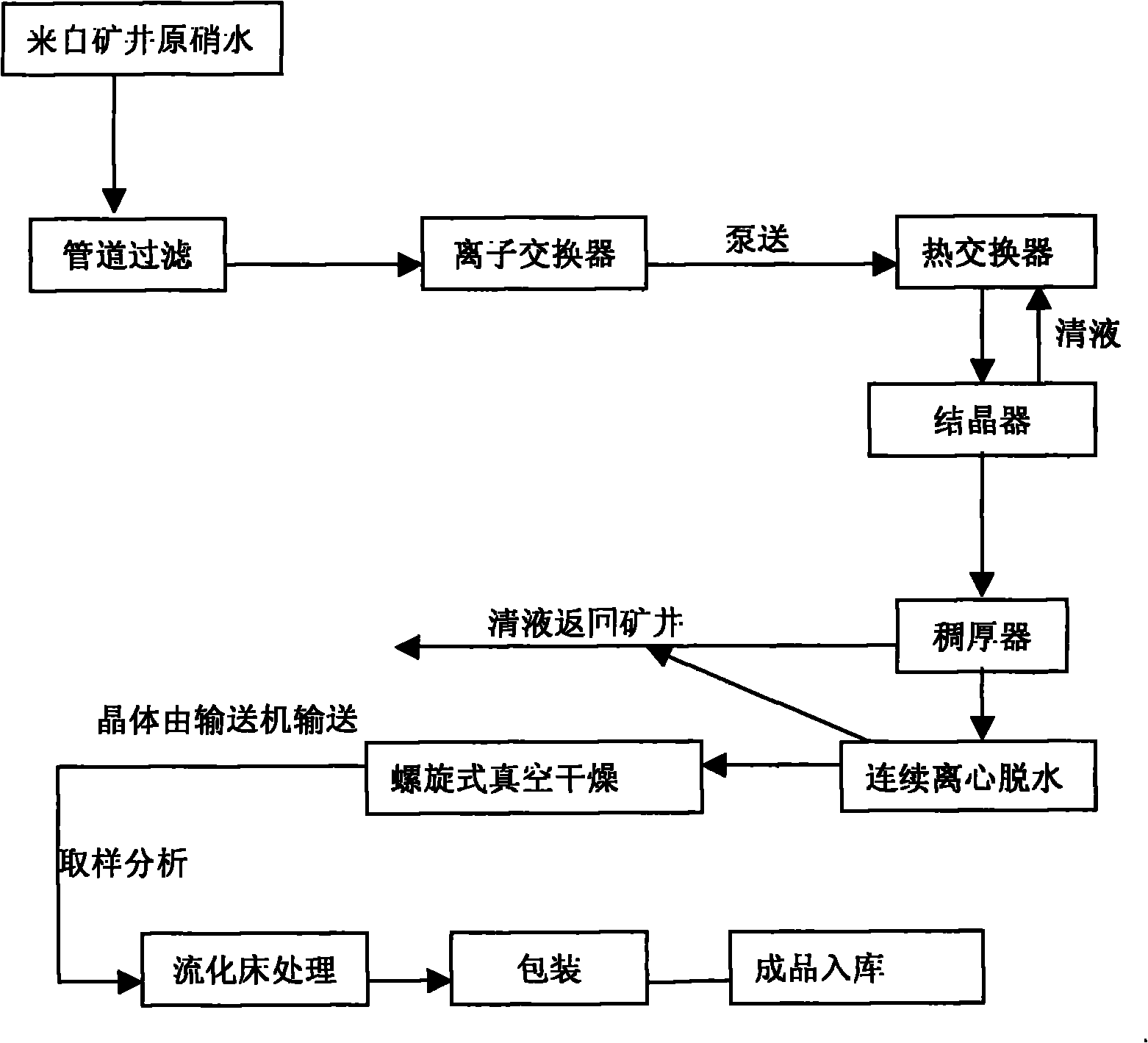

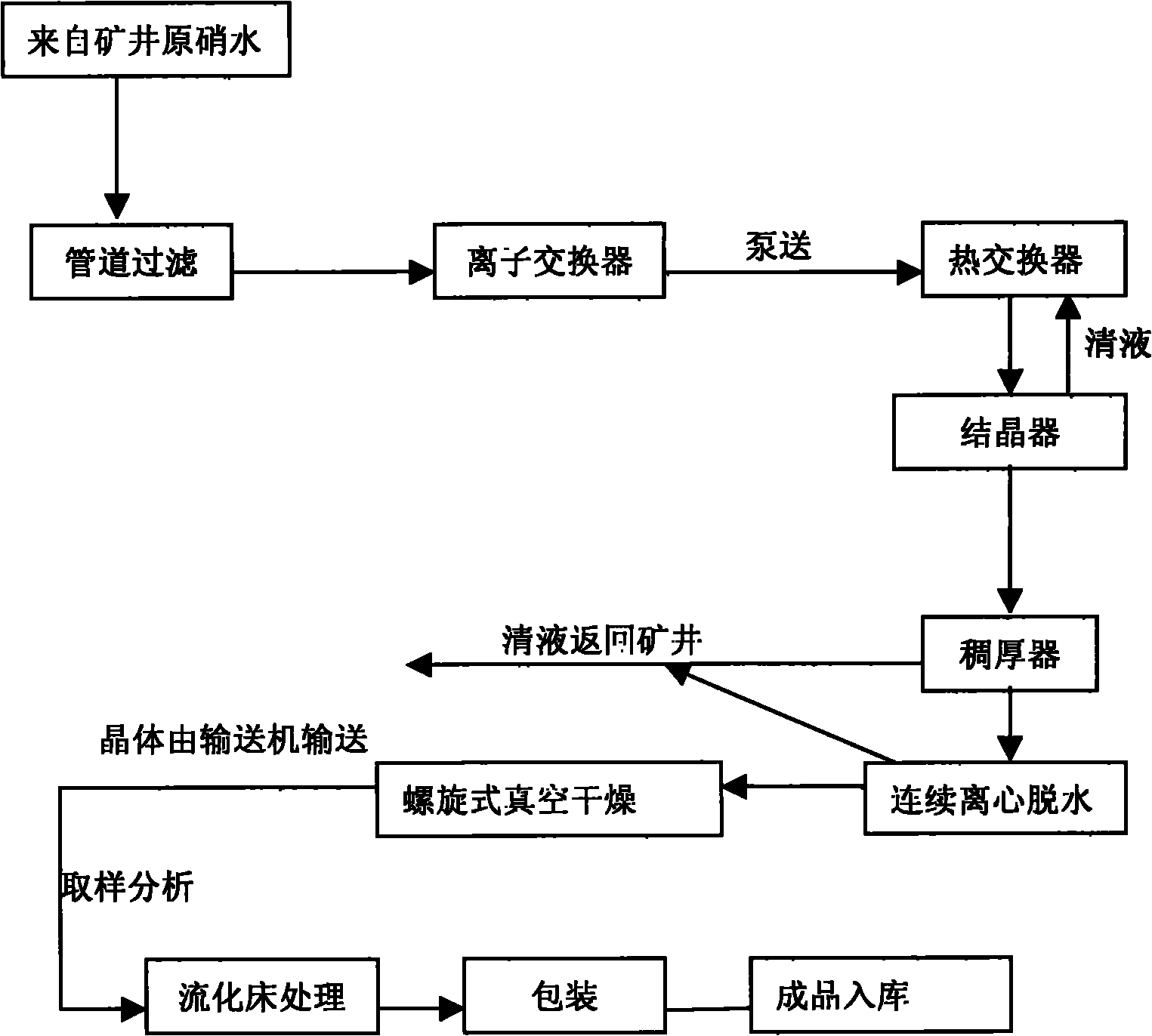

Method used

Image

Examples

Embodiment 1

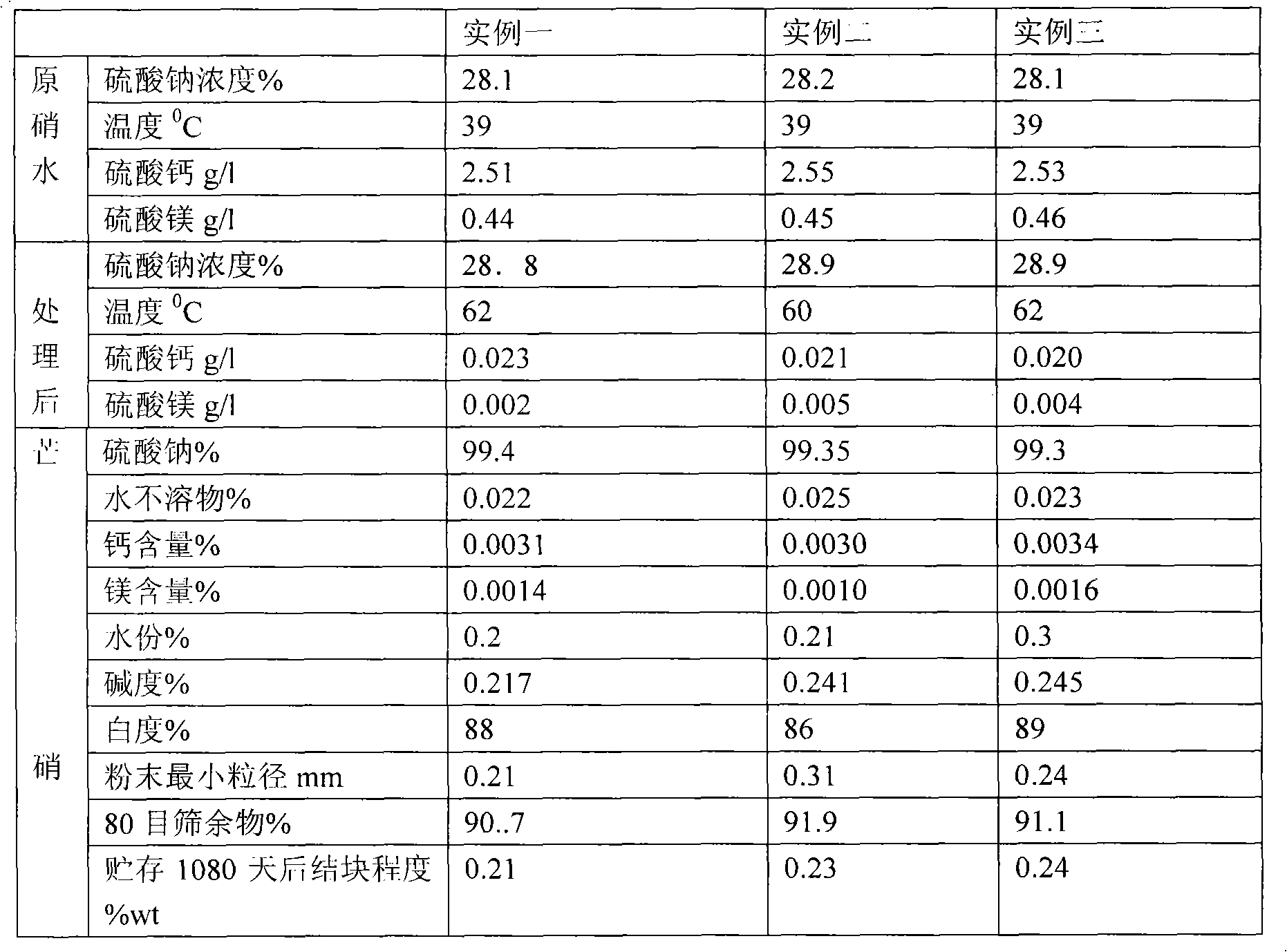

[0039] Example 1: Under the monitoring of the DCS automatic monitoring system and the control of the AK liquid balance flowmeter, the 24°Be concentration raw nitrate transported downhole is obtained by the first-stage pipeline filter to remove mechanical impurities, and the fourth-stage ion exchanger is refined and purified. The refined nitrate with very low impurity content is input into the continuous crystallization process system. In the continuous crystallization system, there are heat exchangers, crystallizers and thickeners. The refined nitrate is carried out in the heat exchanger with 1℃ cold water. Heat exchange to form a supersaturated solution containing 20% sodium sulfate crystals-crystal slurry; the crystal slurry is input from the bottom of the crystallizer, and the crystals grow to an average particle size of 2mm in the crystallizer, thus forming a 35% crystal slurry. The supernatant of the saturated solution containing sodium sulfate in the upper part returns t...

Embodiment 2

[0040] Example 2: Under the monitoring of the DCS automatic monitoring system and the control of the AK liquid balance flowmeter, the 24Be concentration raw nitrate transported downhole is removed through the three-stage pipeline filter to remove mechanical impurities, and the eight-stage ion exchanger is refined and purified to obtain extremely low The refined nitrate with impurity content is input to the continuous crystallization process system. In the continuous crystallization system, there are heat exchangers, crystallizers, and thickeners. The refined nitrate is heat exchanged with 3℃ cold water in the heat exchanger. , To form a supersaturated solution containing 20% sodium sulfate crystals-crystal slurry mixture; the crystal slurry is input from the bottom of the crystallizer, and the crystals grow in the crystallizer to an average particle size of 3mm, thereby forming a 40% crystal slurry. The upper part of the saturated solution containing sodium sulfate returns fro...

Embodiment 3

[0041] Example 3: Under the monitoring of the DCS automatic monitoring system and the control of the AK liquid balance flowmeter, the 24-30°Be concentration raw nitrate transported downhole is removed through a three-stage pipeline filter to remove mechanical impurities, and an eight-stage ion exchanger is refined and purified The refined nitrate with extremely low impurity content is processed and input into the continuous crystallization process system. In the continuous crystallization system, there are heat exchangers, crystallizers and thickeners. The refined nitrate is mixed with 3℃ in the heat exchanger. The cold water exchanges heat to form a supersaturated solution containing 15% sodium sulfate crystals-crystal slurry; the crystal slurry is input from the bottom of the crystallizer, and the crystals grow to an average particle size of 2.5mm in the crystallizer, thus forming 37% Crystal slurry, the upper part of the saturated solution containing sodium sulfate, the clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com