Preparation method of hexagon stannic disulphide nano slice

A tin disulfide and nanosheet technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of low output, large size, increased cost, etc., and achieve low-cost raw materials, simple operation and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] ①In a 100mL flask, add 0.4mmol of tin tetrachloride pentahydrate and 5mmol of hexadecylamine to 39.3mL of anisole, heat to 60°C and keep for 30 minutes until completely dissolved, then add 0.7mL of carbon disulfide , while adding, continue magnetic stirring to prepare a reaction solution of tin disulfide.

[0016] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50mL polytetrafluoroethylene liner. After reacting at 180°C for 24 hours, the reactor is naturally cooled to 60°C. After centrifugation, wash with absolute ethanol Several times, the sample is vacuum-dried to obtain hexagonal tin disulfide nanosheets.

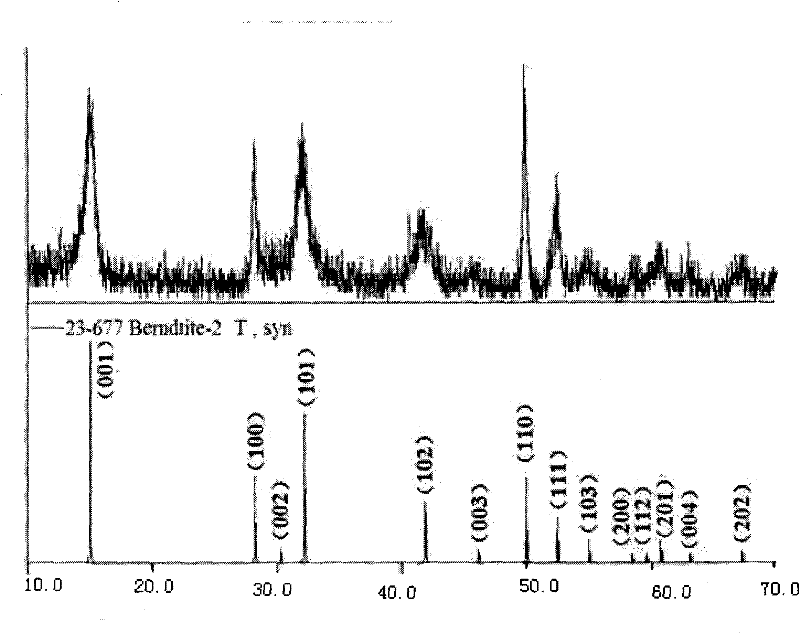

[0017] The X-ray diffraction pattern of the tin disulfide nanoplate of gained hexagonal shape is as attached figure 1 shown. Depend on figure 1 It can be seen that all the diffraction peaks are completely consistent with the standard hexagonal SnS 2 Structure (JPCDS NO.23-677), belonging to P-3ml space group, its uni...

Embodiment 2

[0019] ①In a 100mL flask, add 1mmol of tin tetrachloride pentahydrate and 12mmol of hexadecylamine to 38.5mL of anisole, heat to 60°C and keep for 30 minutes until completely dissolved, then add 1.5mL of carbon disulfide, While adding, continue magnetic stirring to prepare a reaction solution of tin disulfide.

[0020] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50mL polytetrafluoroethylene liner. After solvent heating at 180°C for 48 hours, the reactor is naturally cooled to 55°C. After centrifugation, wash with absolute ethanol After washing several times and vacuum drying the sample, the same hexagonal tin disulfide nanosheets as in Example 1 can be obtained.

Embodiment 3

[0022] ①In a 100mL flask, add 0.4mmol of tin tetrachloride pentahydrate and 2mmol of octadecylamine to 39.4mL of anisole, heat to 60°C and keep for 30 minutes until completely dissolved, then add 0.6mL of carbon disulfide , while adding, continue magnetic stirring to prepare a reaction solution of tin disulfide.

[0023] ②Put the reaction solution prepared according to step ① into a high-pressure reactor with a 50mL polytetrafluoroethylene liner. After solvent heating at 200°C for 24 hours, the reactor is naturally cooled to 60°C. After centrifugation, wash with absolute ethanol After washing several times and vacuum drying the sample, the same hexagonal tin disulfide nanosheets as in Example 1 can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com