Preparation method of hollow ellipsoidal nickel-manganese binary sulfide

An ellipsoidal and sulfide technology, applied in the direction of nickel sulfide, etc., can solve the problems of cumbersome process steps, poor size uniformity, and loose shell structure of the hard template method, and achieve good growth control, uniform appearance, and easy operation. simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

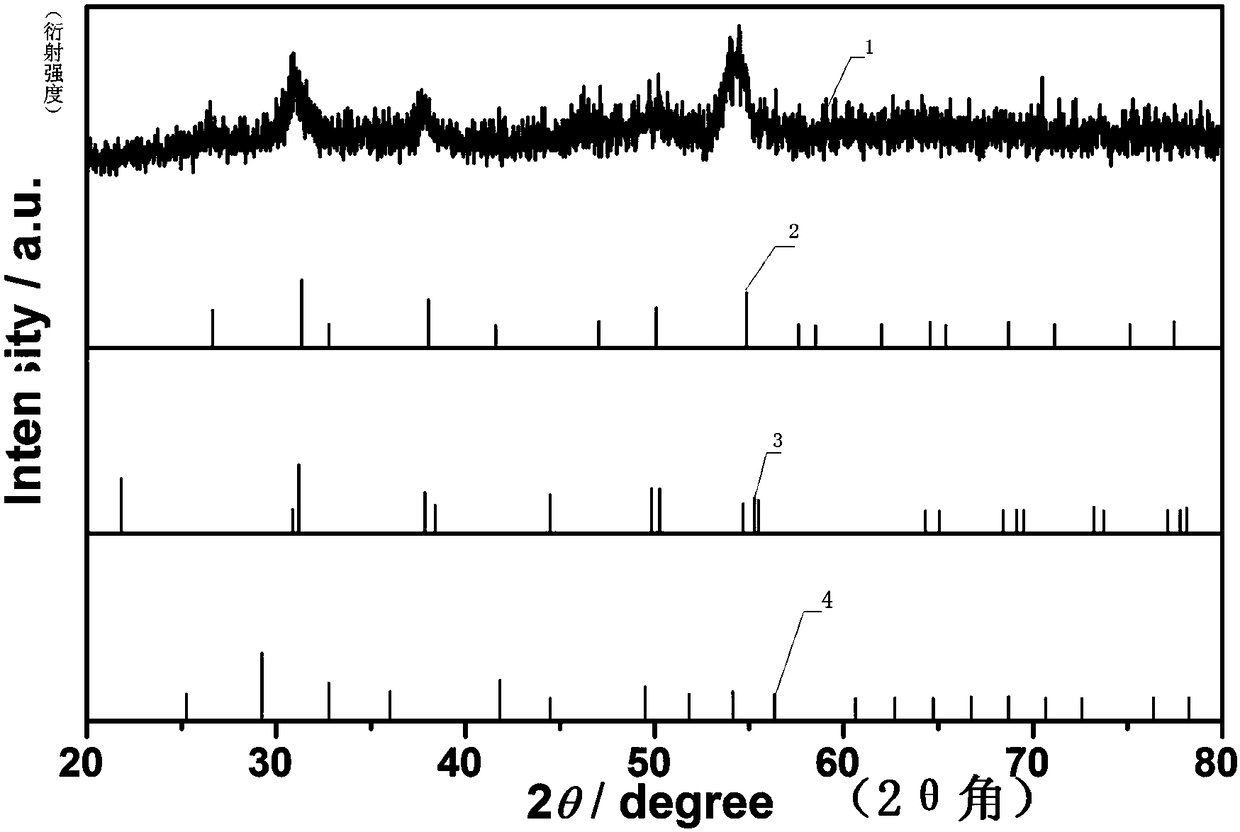

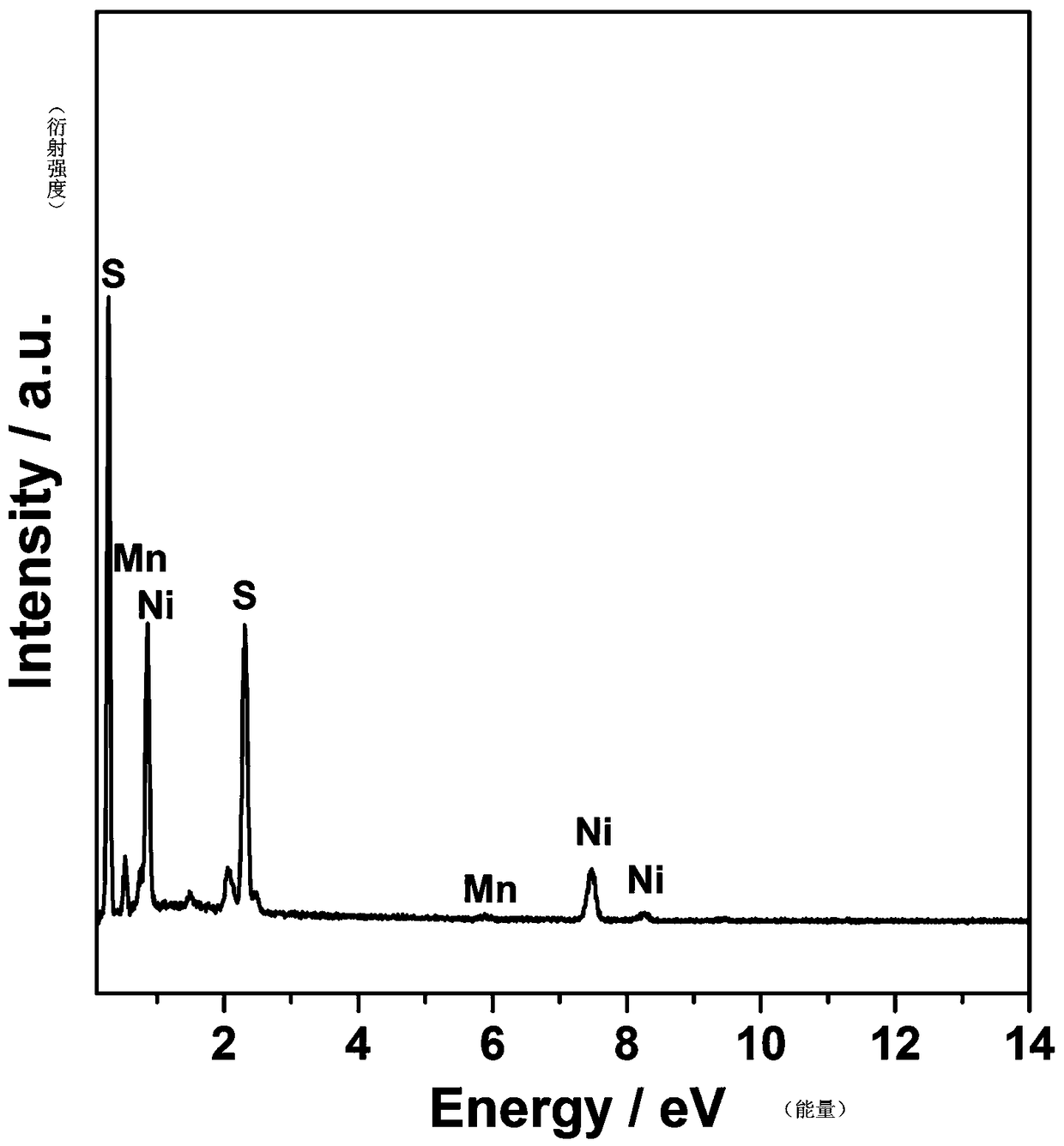

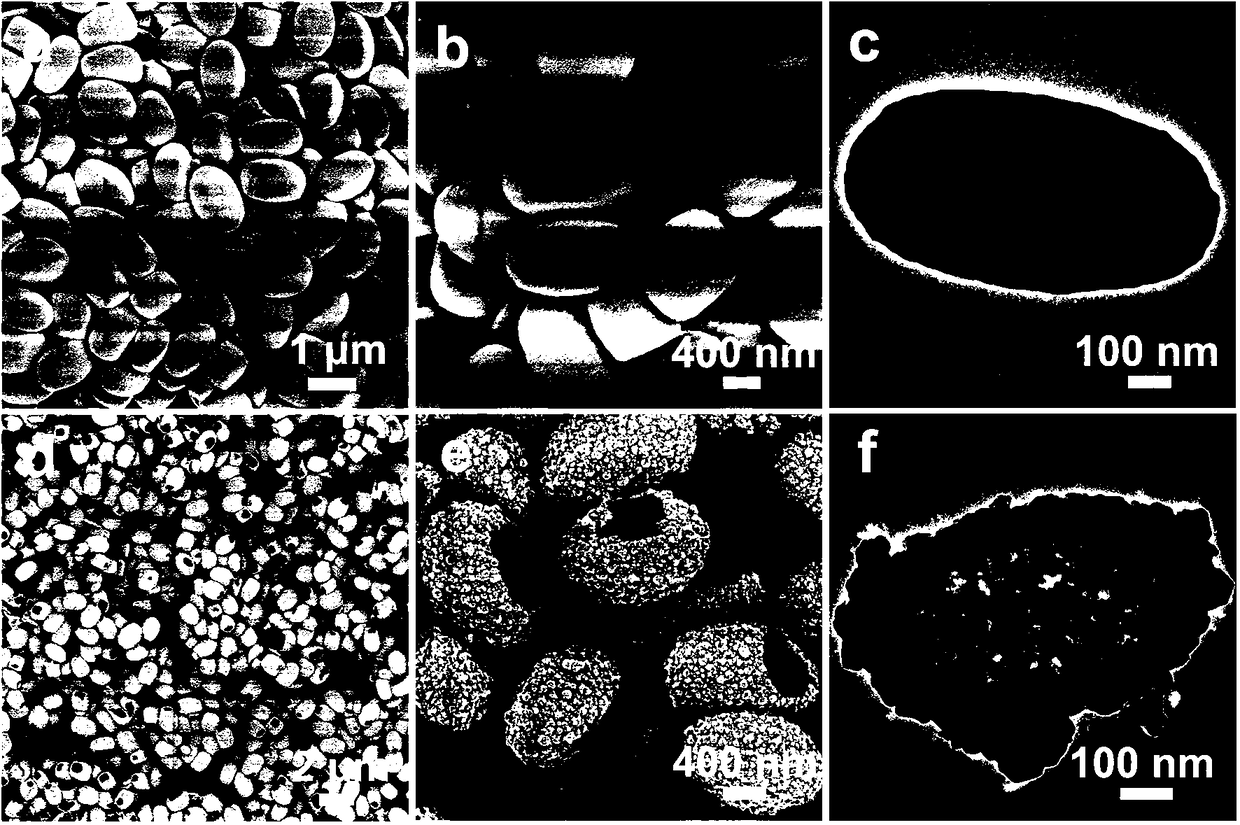

[0016] ① Dissolve 0.55 g nickel acetate tetrahydrate, 0.20 g manganese acetate tetrahydrate and 3.0 g polyvinylpyrrolidone (PVP-K15) in 100 mL absolute ethanol, transfer the above-prepared reaction solution to a round bottom flask, The reaction was refluxed at 90 ℃ for 6.0 h. After the reaction, it was cooled to room temperature naturally, the product was centrifuged, washed with absolute ethanol several times, and dried to obtain a solid ellipsoidal nickel-manganese precursor compound.

[0017] ② Disperse the solid ellipsoidal nickel-manganese precursor compound prepared in step ① into absolute ethanol, then add 0.1125 g of thioacetamide, stir for 30 min, then transfer the reaction solution to the reactor, and react at 140 ℃ After 12.0h, after the reaction, it was cooled to room temperature naturally, the product was centrifuged, washed several times with absolute ethanol, and dried to obtain a hollow ellipsoidal nickel-manganese binary sulfide.

Embodiment 2

[0020] ① Dissolve 0.50 g nickel acetate tetrahydrate, 0.25 g manganese acetate tetrahydrate, 3.0 g polyvinylpyrrolidone (PVP-K15) in 100 mL absolute ethanol, and transfer the above-prepared reaction solution to a round bottom flask. The reaction was refluxed at ℃ for 4.0 h. After the reaction, it was cooled to room temperature naturally, the product was centrifuged, washed with absolute ethanol several times, and dried to obtain a solid ellipsoidal nickel-manganese precursor compound.

[0021] ② Disperse the solid ellipsoidal nickel-manganese precursor compound prepared in step ① into absolute ethanol, then add 0.1125 g of thioacetamide, stir for 60 minutes, then transfer the reaction solution to the reactor, and react at 120 ℃ After 6.0 h, after the reaction is over, cool to room temperature naturally, centrifuge the product, wash it with absolute ethanol several times, and dry it to obtain the same hollow ellipsoidal nickel-manganese binary sulfide as in Example 1.

Embodiment 3

[0023] ① Dissolve 0.70 g nickel acetate tetrahydrate, 0.05 g manganese acetate tetrahydrate and 3.0 g polyoxypropylene polyoxyethylene copolymer (P123) in 100 mL absolute ethanol, and transfer the above-prepared reaction solution to a round bottom flask The reaction was refluxed at 90 ℃ for 4.0 h. After the reaction, it was cooled to room temperature naturally, the product was centrifuged, washed with absolute ethanol several times, and dried to obtain a solid ellipsoidal nickel-manganese precursor compound.

[0024] ② Disperse the solid ellipsoidal nickel-manganese precursor compound prepared in step ① into absolute ethanol, then add 0.1125 g of thioacetamide, stir for 30 min, then transfer the reaction solution to the reactor, and react at 140 ℃ After 3.0 h, after the reaction, it was cooled to room temperature naturally, the product was centrifuged, washed with absolute ethanol several times, and dried to obtain the same hollow ellipsoidal nickel-manganese binary sulfide as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com