Miniature microphone manufacturing method based on Si-Si bonding process

A microphone and silicon-silicon bond technology, which is applied in the field of micro-microphone preparation based on the silicon-silicon bonding process, can solve the problems of extremely high process control requirements, poor repeatability, and increased process complexity, and achieve simple process implementation, Meet the effect of small size and avoid adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0031] The preparation method of the miniature microphone of the present invention mainly utilizes a silicon-silicon bonding process to form a capacitive miniature microphone.

[0032] The micro-microphone preparation method based on the silicon-silicon bonding process comprises the following steps:

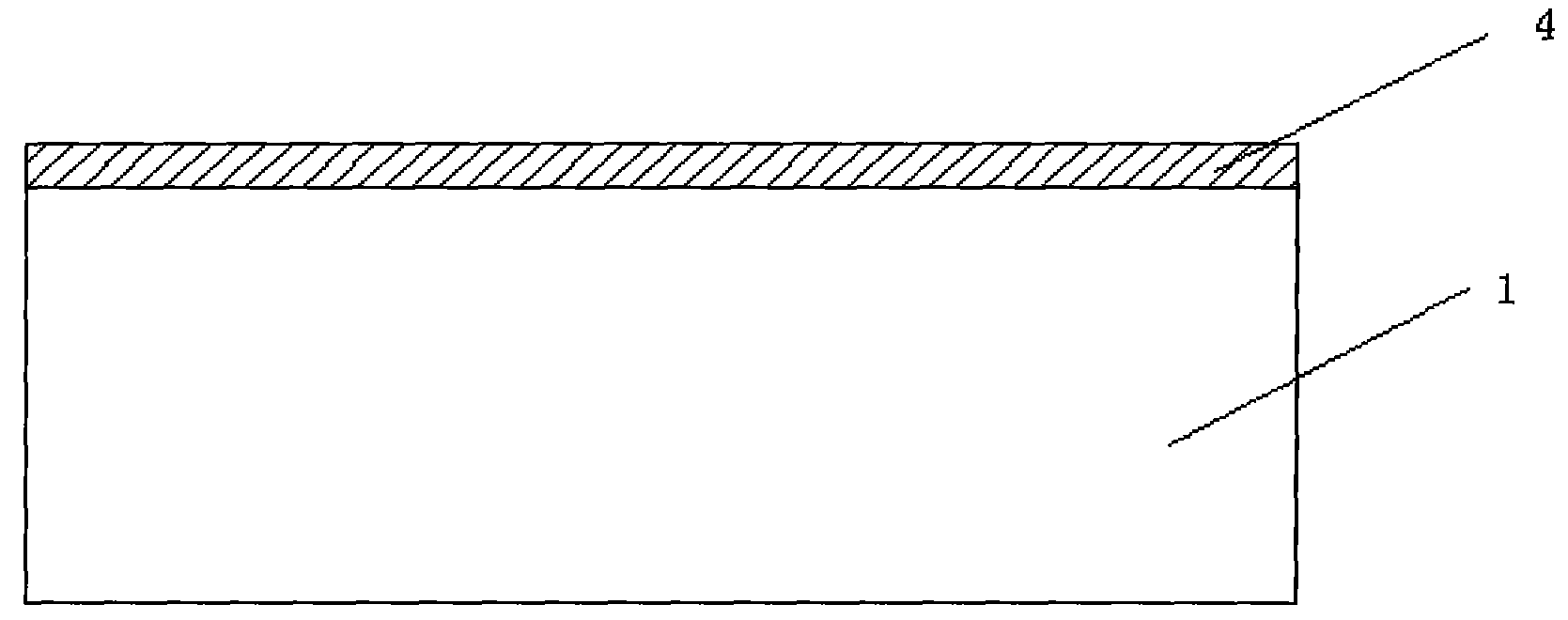

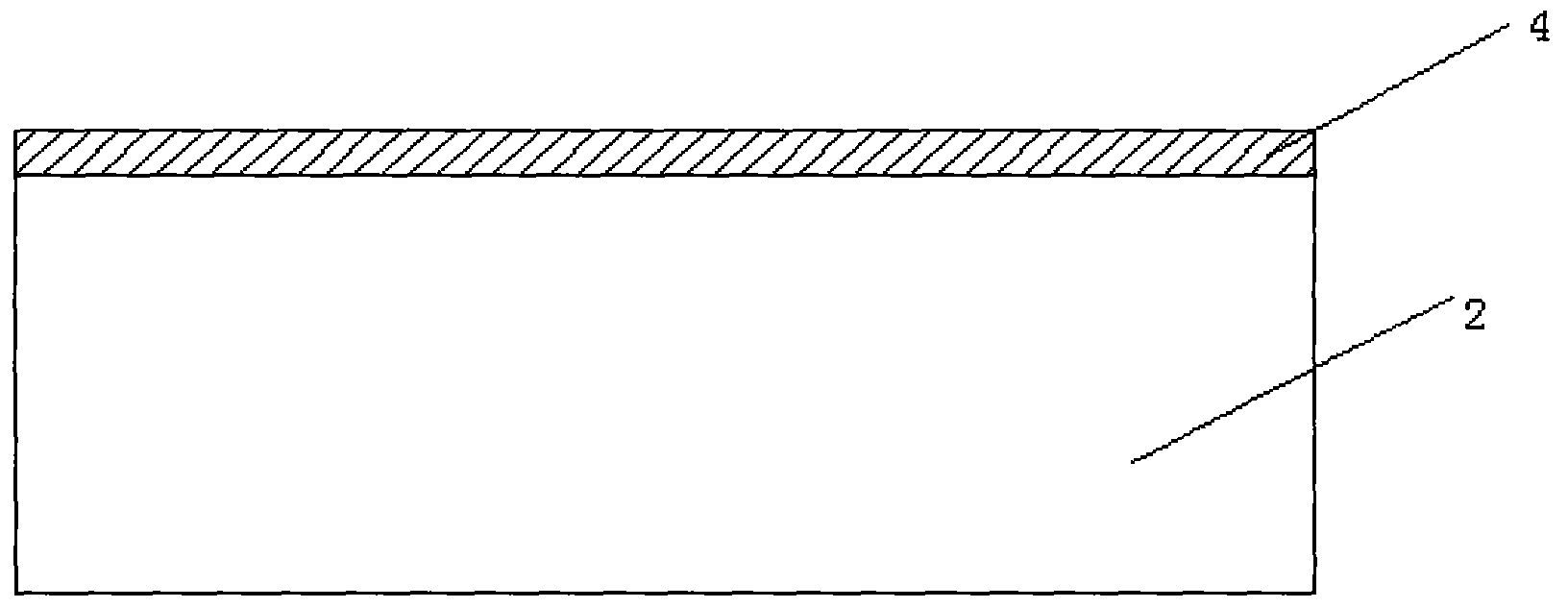

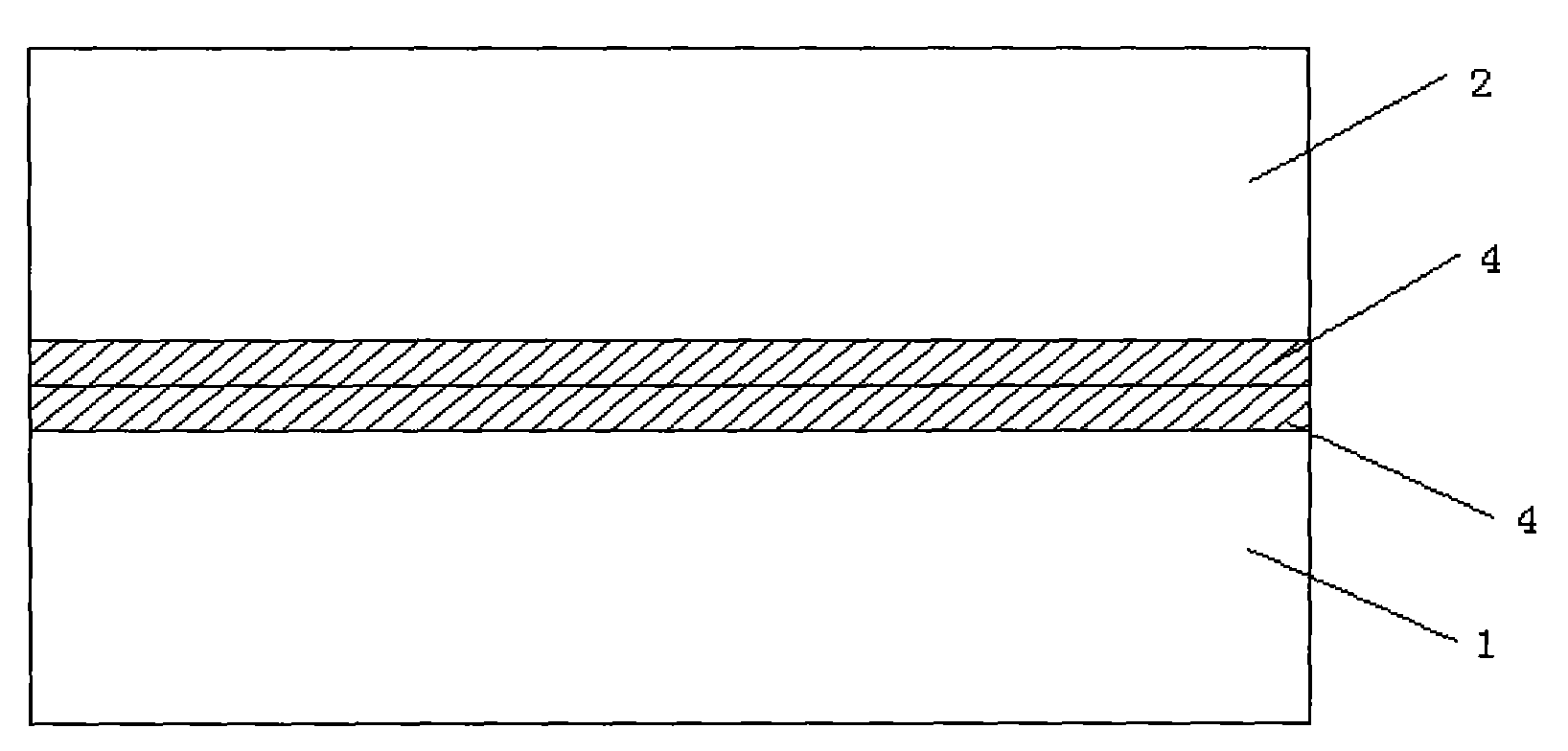

[0033] a. A connection plate 1 and a back plate 2 are provided, and an oxide layer 4 is grown on the connection plate 1 and the back plate 2; the connection plate 1 is monocrystalline silicon, and the material of the back plate 2 is doped Single crystal silicon; the oxide layer 4 is silicon dioxide, and the connection plate 1 and the back plate 2 are bonded and fixed by the corresponding oxide layer 4; the connection plate 1 is mainly used for the reliability of the thinning process of the back plate 2; The structures of plate 1 and back plate 2 are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com