Method for extracting sweet almond oil from sweet almond and method for separating protein

A technology of sweet almond oil and almond, which is applied in the field of oil and protein extraction, can solve problems such as emulsification, and achieve the effect of increasing added value, increasing yield, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one: the preparation technology of sweet almond oil and protein thereof

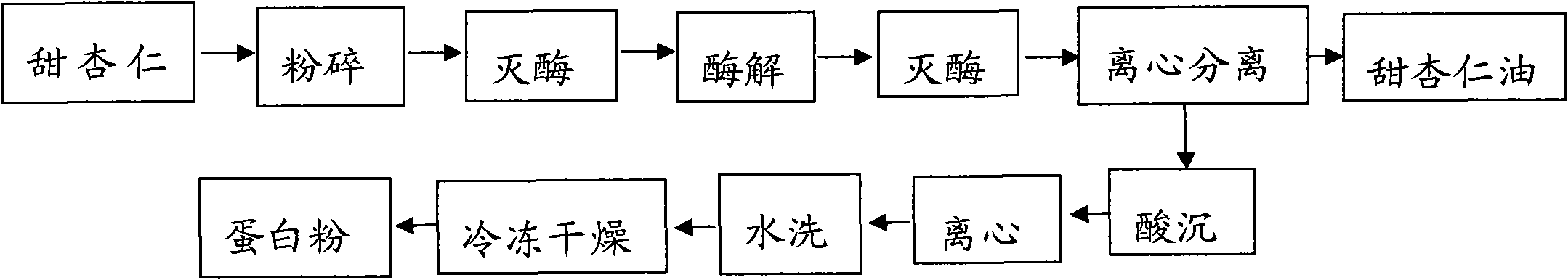

[0033] See attached figure 1 , the preparation steps of extracting sweet almond oil and protein thereof from sweet almonds are as follows:

[0034] (1) 1Kg of dried and pulverized sweet almonds are placed in an enzymatic hydrolysis tank.

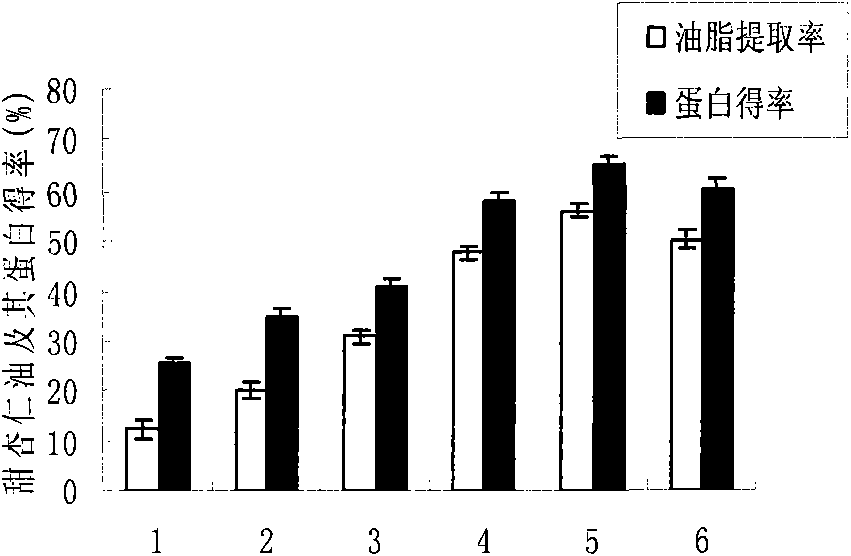

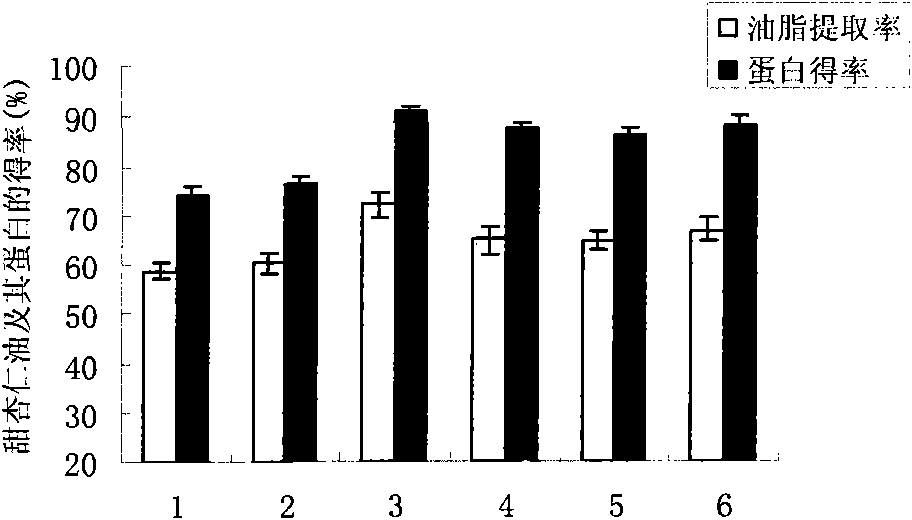

[0035] (2) Add ionized water to sweet almonds, the solid-to-liquid ratio is 1:5 according to the mass of sweet almonds: the volume ratio of deionized water, rapidly heat up to 85-90°C, maintain for 10min, and cool down to room temperature rapidly after enzymatic inactivation treatment. Use NaOH to adjust the pH value to 7.0, carry out enzymolysis temperature 35 ℃, under this condition, add enzyme according to the mass ratio of compound enzyme (cellulase+neutral protease): the sweet almond ratio is 1: 100, in the compound enzyme The mass ratio of cellulase:neutral protease is 1:1, the enzymolysis is stirred for 1 hour, and then the temperature is rap...

Embodiment 2

[0041] Embodiment two: the preparation technology of sweet almond oil and protein thereof

[0042] See attached figure 1 , the preparation steps of extracting sweet almond oil and protein thereof from sweet almonds are as follows:

[0043] (1) After drying 1Kg of sweet almonds, pulverize them with a pulverizer and place them in an enzymatic hydrolysis tank.

[0044] (2) Add deionized water with a solid-to-liquid ratio (mass of sweet almond: volume of deionized water) of 1:4 to the sweet almond, rapidly raise the temperature to 85-90°C, keep it for 10min, and cool down to room temperature rapidly after enzyme-inactivating treatment. Adjust the pH value to 8.5 with NaOH, carry out enzymolysis temperature 50 ℃, under this condition, add enzyme according to the mass ratio of (cellulase+alkaline protease): sweet almond is 1:100, enzymolysis and stirring for 2 hours, (cellulase:alkaline protease=2:3) then rapidly raise the temperature to 85-90°C, maintain it for 10min, and carry o...

Embodiment 3

[0050] Embodiment three: the preparation technology of sweet almond oil and protein thereof

[0051] See attached figure 1 , the preparation steps of extracting sweet almond oil and protein thereof from sweet almonds are as follows:

[0052] (1) After drying 1Kg of sweet almonds, pulverize them with a pulverizer and place them in an enzymatic hydrolysis tank.

[0053] (2) Add deionized water with a solid-to-liquid ratio (mass of sweet almond: volume of deionized water) of 1:3 to the sweet almond, rapidly raise the temperature to 85-90°C, maintain it for 10 minutes, and cool down to room temperature rapidly after enzymatic inactivation treatment. Adjust to pH value 9.0 with NaOH, carry out enzymolysis temperature 55 ℃, under this condition, according to (cellulase+neutral protease): the mass ratio of sweet almond is 1: 100 to add enzyme (cellulase: neutral protease). Protease = 2:3), enzymatic hydrolysis and stirring for 3 hours, and then rapidly raised the temperature to 85-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com