Diamond film coating steel matrix composite material and preparation method thereof

A technology of diamond film and composite materials, applied in the direction of metal material coating process, coating, metal layered products, etc., to achieve high bonding strength and eliminate negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In order to solve the above-mentioned second technical problem, the preparation method of the diamond film-coated steel-based composite material provided by the present invention comprises the following steps:

[0075] (1) Mechanically polish and remove oil stains on steel substrates;

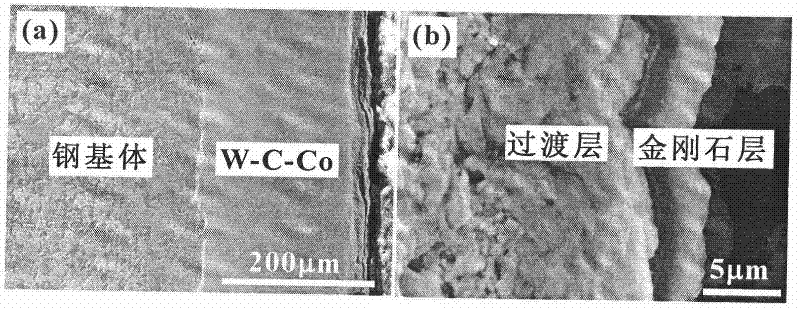

[0076] (2) Prepare a layer of W—C—Co intermediate layer on the surface of the steel base material, wherein the mass percentage of Co is 1-30%.

[0077] (3) Surface treatment of the W-C-Co intermediate layer, including grinding and polishing, to control the surface roughness;

[0078] (4), carry out the pretreatment before the growth of diamond superhard wear-resistant layer to W-C-Co intermediate layer;

[0079] (5) A diamond superhard wear-resistant layer is prepared on the surface of the treated sample by chemical vapor deposition.

[0080] The preparation method of the W-C-Co intermediate layer described in the described step (2) includes all techniques that can be used to prepare t...

Embodiment 1

[0091] First, the W-C-Co intermediate layer was prepared on the carbon steel substrate by thermal spraying technology, and then Ti / Cu / Ti / Cu / ... / Ti / Cu / Ti / TiC was prepared on the W-C-Co layer by PVD technology Composite transition layer. Before chemical vapor deposition, the sample was ultrasonically treated with diamond powder acetone suspension for 5-60 minutes, the surface of the sample was cleaned with acetone and dried with a fan, and then the diamond film was prepared by HFCVD technology. During the chemical vapor deposition process, the distance between the sample and the filament is 5-20mm, using CH 4 and H 2 is the reaction gas, CH 4 The concentration is 0.5%-8%, and the deposition time is 5-6 hours. During the deposition process, the distance between the filament and the substrate is 5-20mm.

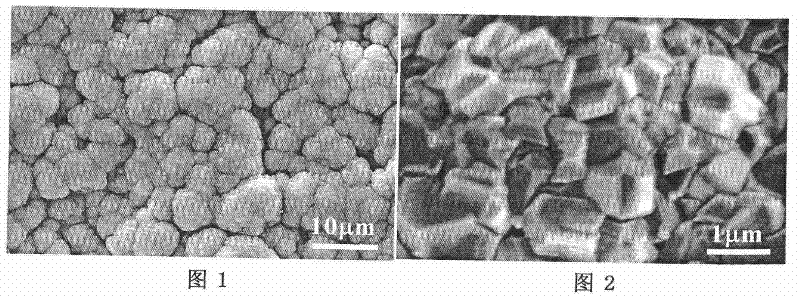

[0092] The surface morphology of the Ti / Cu / Ti / Cu / ... / Ti / Cu / Ti / TiC composite transition layer prepared on the thermal sprayed W-C-Co carbon steel substrate is as follows figu...

Embodiment 2

[0095] First, the W-C-Co intermediate layer was prepared on the carbon steel substrate by thermal spraying technology, and then the Ti / TiCN / TiC composite transition layer was prepared on the W-C-Co layer by PVD technology. Before chemical vapor deposition, the sample was ultrasonically treated with diamond powder acetone suspension for 5-60 minutes, the surface of the sample was cleaned with acetone and dried with a fan, and then the diamond film was prepared by HFCVD technology. During the chemical vapor deposition process, the distance between the sample and the filament is 5-20mm, using CH 4 and H 2 is the reaction gas, CH 4 The concentration is 0.5%-8%, and the deposition time is 5-6 hours. During the deposition process, the distance between the filament and the substrate is 5-20mm.

[0096] The surface morphology of the Ti / TiCN / TiC composite transition layer prepared on the thermal sprayed W-C-Co carbon steel base material is as follows Image 6 As shown; under this p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com