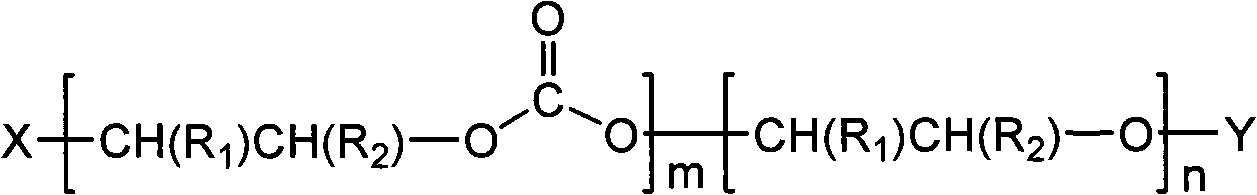

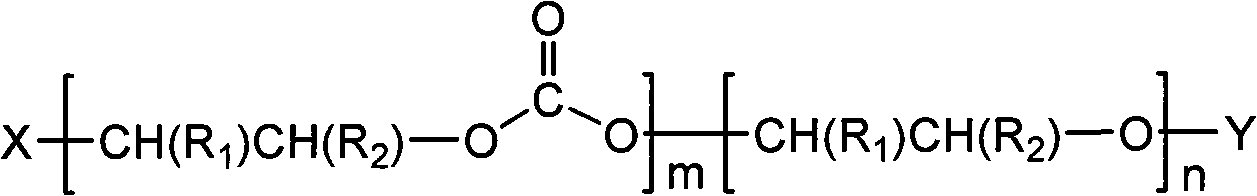

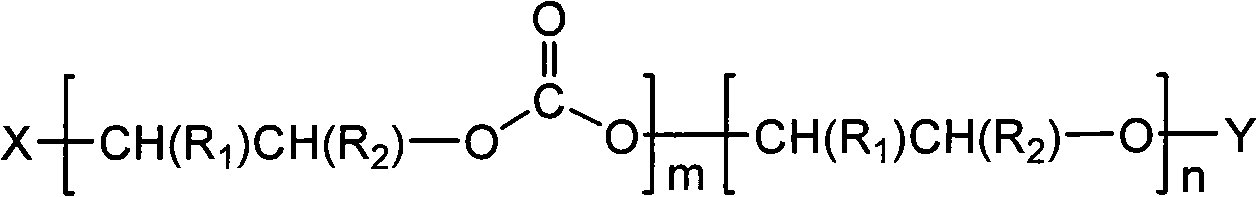

Polyurethane microporous elastomer, preparation method and application thereof

A microporous elastomer and polyurethane technology, applied in the field of polyurethane, can solve the problems of poor mechanical properties, easy hydrolysis, easy mildew, etc., achieve good physical and mechanical properties, realize environmental protection utilization, and reduce demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Preparation of soles

[0075] According to an embodiment of the present invention, the polyurethane elastomer provided by the present invention can be used for making shoes, including parts such as shoe soles.

[0076] The specific embodiments and methods disclosed herein are described by way of illustration and not limitation.

[0077] Raw materials mentioned in context are described below

[0078] Bayflex 2003E: polyester polyol, with an average molecular weight of 2000 and a hydroxyl value of 56 mg KOH / g, available from Bayer Material Technology Co., Ltd.

[0079] Arcol 1026: polyether polyol, with an average molecular weight of 4000 and a hydroxyl value of 28 mg KOH / g, available from Bayer Material Technology Co., Ltd.

[0080] Arcol 1362: polyether polyol, with an average molecular weight of 6000 and a hydroxyl value of 28 mg KOH / g, available from Bayer Material Technology Co., Ltd.

[0081] Hyperlite E851: polyether polyol, hydroxyl value of 18.5mg KOH / g, a...

Embodiment 1-4

[0090] Add the 4,4'-MDI and polyol in the amount listed in Table 1 into the reaction kettle, react at 70°C for 2 hours, cool the reaction kettle to 65°C, and modify the carbimide with the amount listed in Table 1. MDI (CD-MDI) was added to the reaction kettle and stirred for 30 minutes, and cooled to room temperature to obtain isocyanate-terminated prepolymers A1-A4.

Embodiment 5

[0092] Add the 4,4'-MDI and polyol in the amount listed in Table 1 into the reaction kettle, react at 60°C for 2 hours, cool the reactor to 50°C, and modify the carbodiimide in the amount listed in Table 1. The MDI (CD-MDI) was added to the reaction kettle and stirred for 30 minutes, and cooled to room temperature to obtain the isocyanate-terminated prepolymer A5.

[0093] Table 1 Preparation of isocyanate terminated prepolymers

[0094]

[0095] As shown in Table 1,

[0096] In Examples 1 and 5, in the process of preparing the isocyanate-terminated prepolymer, the polycarbonate polyol prepared by the reaction of carbon dioxide and an epoxy compound was not added; in Examples 2-4, in the preparation of the isocyanate-terminated prepolymer In the process of polymerizing, a polycarbonate polyol prepared by the reaction of carbon dioxide and an epoxy compound is added.

[0097] Preparation of Polyurethane Microcellular Elastomer

[0098] The isocyanate-terminated prepolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com