Method for self assembling non-spherical polystyrene grains to form into multihole and ordered structure

A technology of polystyrene particles and ordered structures, applied in the field of self-assembly of non-spherical polymer particles and the preparation of porous ordered structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The soap-free emulsion polymerization for the preparation of monodisperse core-shell solid crosslinked polystyrene (PS) microspheres was carried out in a 250 mL four-necked flask with a stirrer and a condenser tube: first, styrene (St) was added to the flask 2. A mixture of 70g and 90mL of deionized water, start stirring (200rpm), blow nitrogen to remove oxygen for 30min; then, turn on condensed water, turn on the water bath and raise the temperature to 70°C, add 0.12g of initiator potassium persulfate (KPS) and 10mL of deionized The mixed solution of water is recorded as the beginning of soap-free emulsion polymerization at this time. After the polymerization reaction is carried out for 3 hours, divinylbenzene (DVB) is added successively using a micro-injector (1 minute, 20 μL each time, and the final balance Less than 20 μL is also added at the last time), the total amount of DVB is used to control the cross-linking degree of polystyrene microspheres to be 10% to 11%, ...

Embodiment 2

[0029] The preparation of monodisperse core-shell solid cross-linked polystyrene microspheres is the same as in Example 1.

[0030] Put 0.3g of monodisperse cross-linked core-shell solid polystyrene microsphere powder sample and 36mL of chloroform into a 100mL three-necked flask, turn on the condensed water, and dissolve at a constant temperature of 42°C for 6h under constant stirring (200rpm); then, Collect the product, add acetone, repeat ultrasonic dispersion, centrifuge (rotating speed 9000rpm, time 8min) and wash 3 to 4 times; finally, the washed product part is directly dispersed in acetone to form a hollow cross-linked polymer with a concentration of 0.01g / ml. Styrene microspheres / acetone suspension.

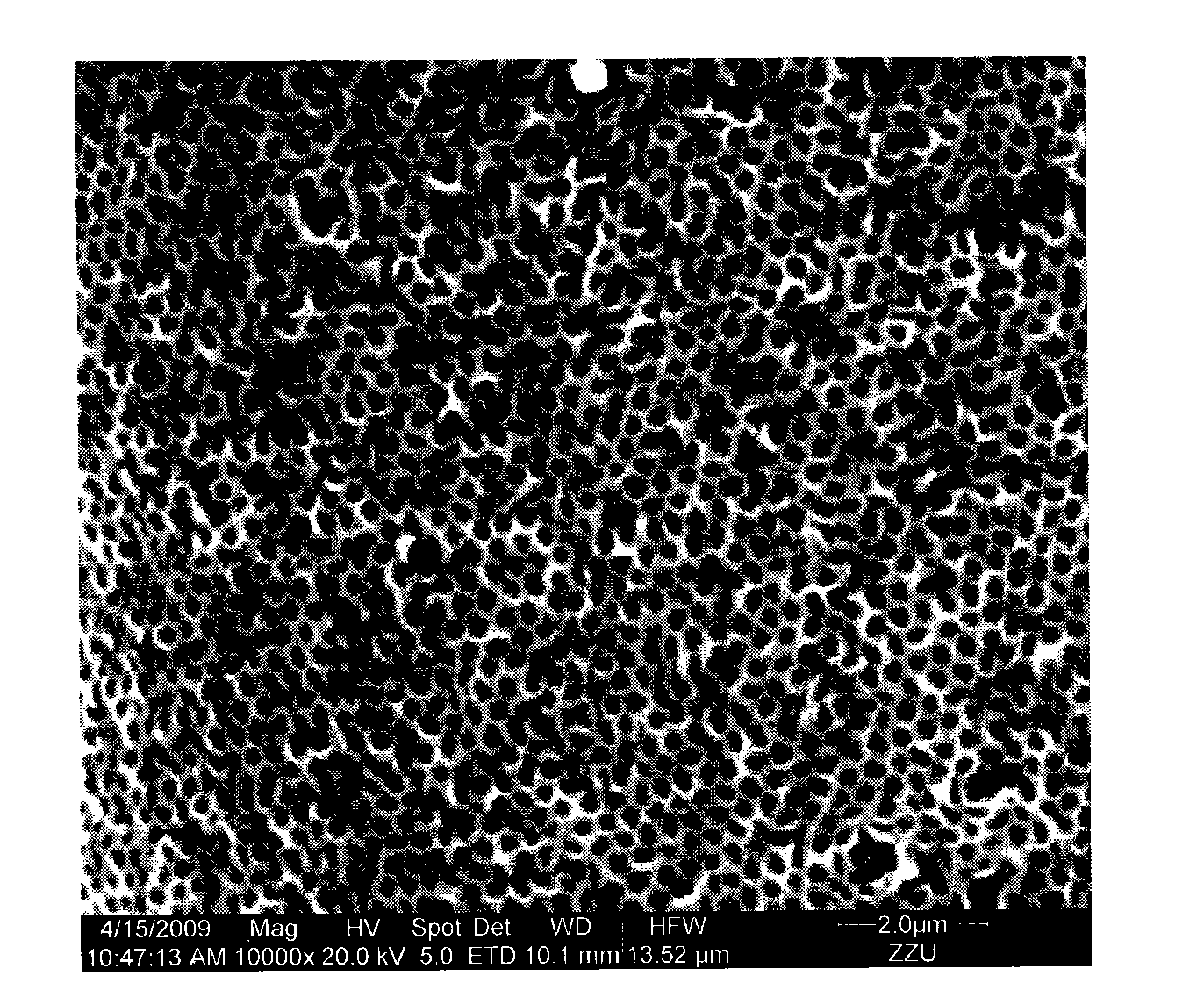

[0031] Drop the hollow cross-linked polystyrene microspheres / acetone suspension on the glass with a drop volume of 0.015-0.020ml in an oven environment at 30°C, and dry at a constant temperature for 8 hours to obtain quasi-hexagonal bowl-shaped hollow cross-linked polysty...

Embodiment 3

[0033] The preparation of monodisperse core-shell solid cross-linked polystyrene microspheres is the same as in Example 1.

[0034] Put 0.3g of monodisperse cross-linked core-shell solid polystyrene microsphere powder sample and 33mL tetrahydrofuran into a 100mL three-necked flask, turn on the condensed water, and dissolve at a constant temperature of 38°C for 12h under constant stirring (180rpm); then, Collect the product, add acetone, repeat ultrasonic dispersion, centrifuge (8000rpm, time 10min) and wash 3 to 4 times; finally, the washed product part is directly dispersed in acetone to form a hollow cross-linked polymer with a concentration of 0.008g / ml. Styrene microspheres / acetone suspension.

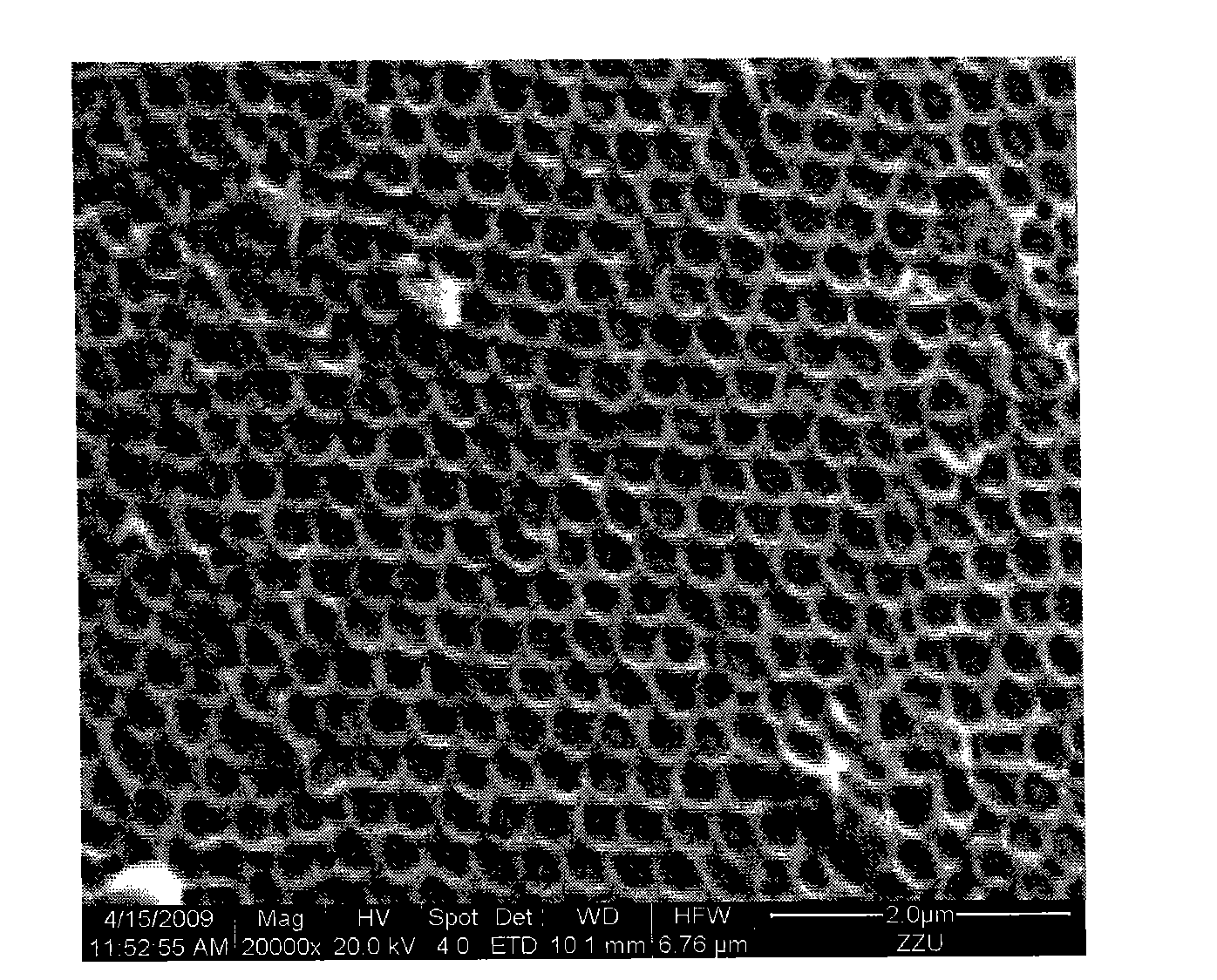

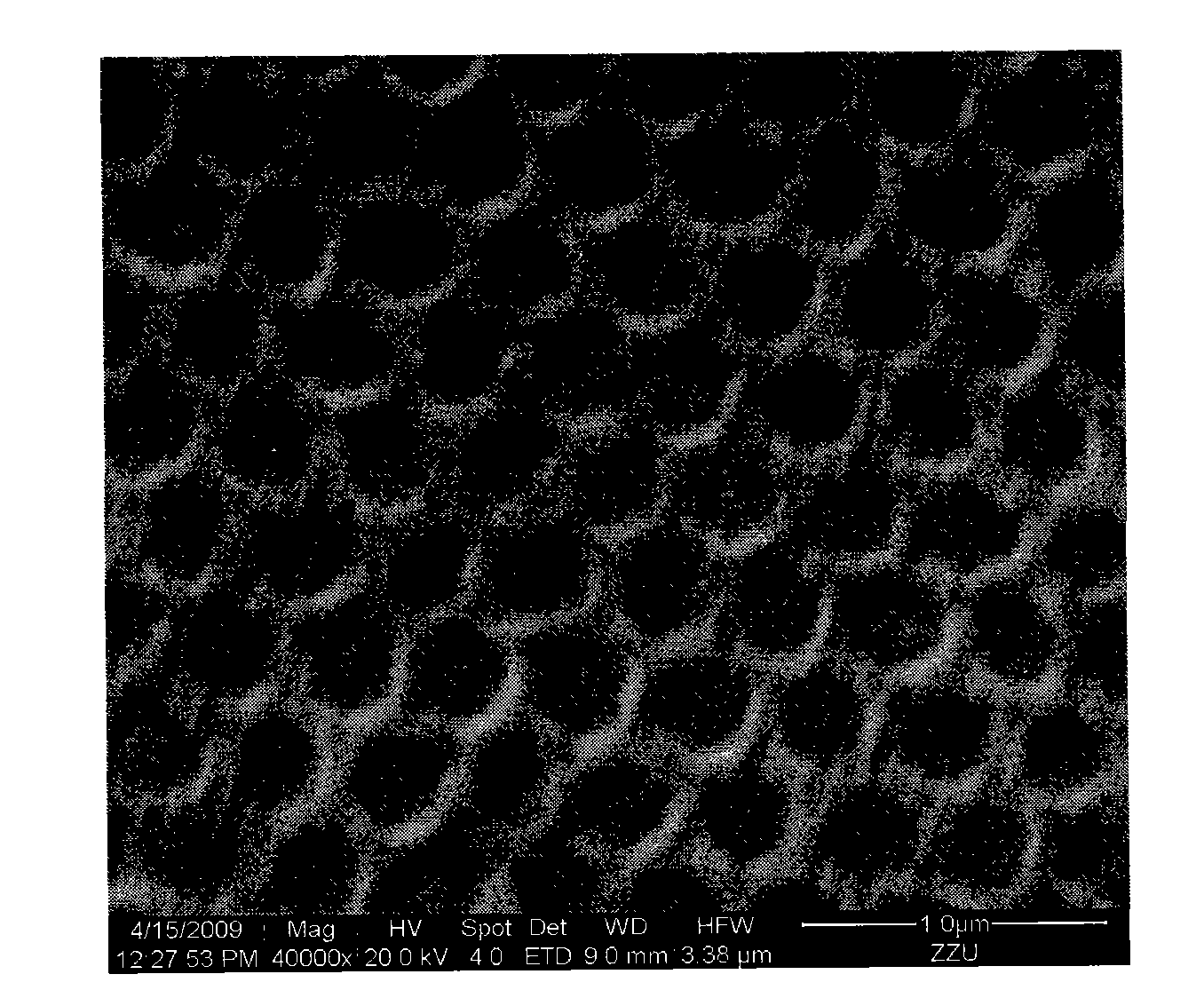

[0035]Drop the hollow cross-linked polystyrene microsphere / acetone suspension on the mica with a drop volume of 0.015-0.020ml in an oven environment at 50°C, and dry at a constant temperature for 5 hours to obtain hexagonal bowl-shaped cross-linked polystyrene microsphere particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com