Preparation method of high-temperature and high-power field effect transistor

A field-effect transistor, high-power technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as many defects, difficult to increase speed, disordered polycrystalline diamond film grain boundaries, etc., and achieve good temperature stability sex, performance-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

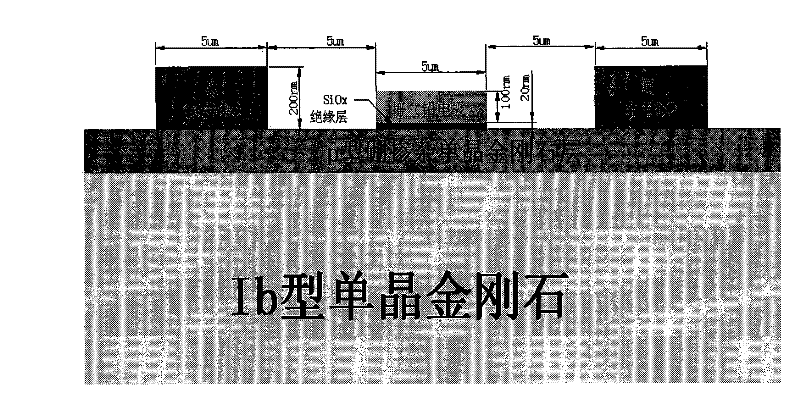

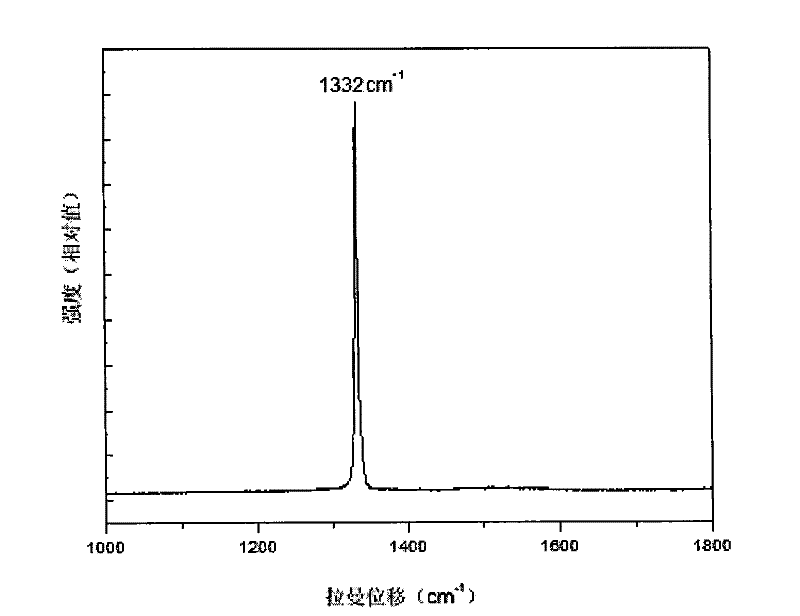

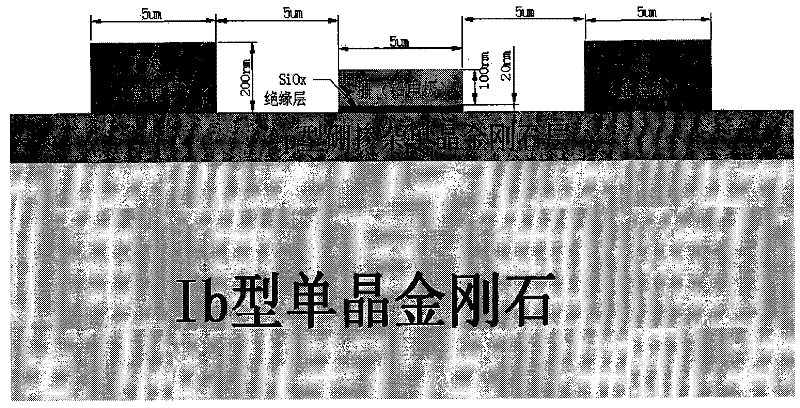

[0024] In this embodiment, the preparation process and steps of a semiconductor field effect transistor based on a p-type doped single crystal diamond film are as follows:

[0025] (1) Preparation of p-type boron-doped single-crystal diamond thin film: use purchased 2×2mm 2 I b type single crystal diamond as the deposition substrate. Ultrasonic cleaning in acetone solution for 10 minutes, dried and placed in a microwave plasma chemical vapor deposition (MPCVD) device.

[0026] First use a vacuum pump to evacuate the MPCVD reaction chamber to 5Pa, and then use a molecular pump to evacuate the reaction chamber to 5×10 -3 Pa, feed the mixed reaction gas of methane, hydrogen and diborane, adjust the flow of methane, hydrogen and diborane to be 1 standard ml / min, 120 standard ml / min and 2 standard ml / min respectively; the air pressure in the reaction chamber The setting is 0.2kPa, the substrate temperature is controlled at 690°C, the microwave power is set at 2350W, and the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com