Direct current/ direct current converter and direct current/ direct current converting method

A DC converter and comparator technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems of limited bandwidth of voltage adder XADD, complex ISENSE module, distortion of current detection signal, etc., to overcome efficiency and detection accuracy Contradictions, reduced structural complexity, and the effect of avoiding bandwidth limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

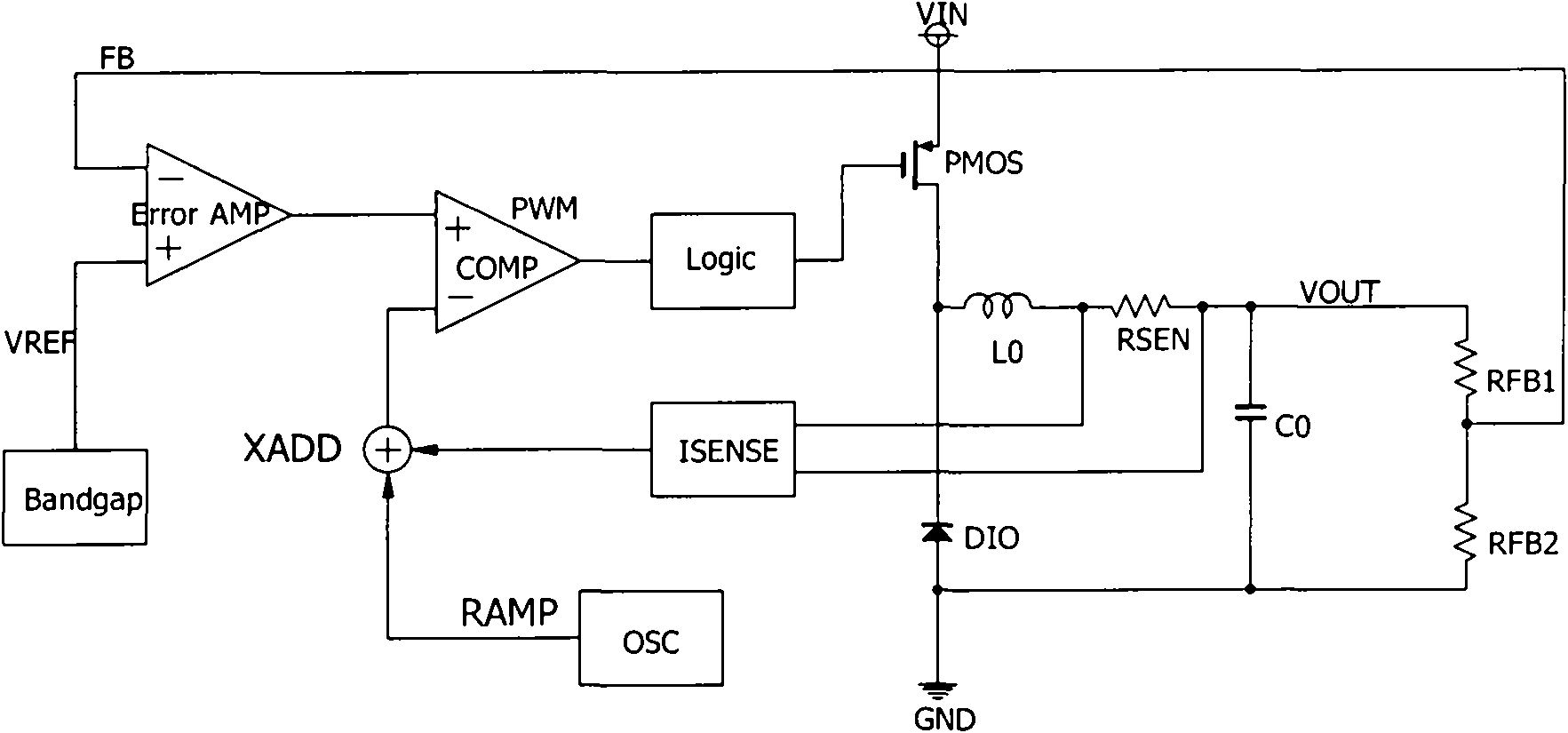

[0091] This embodiment firstly describes the main frame structure of a DC / DC converter provided by the technical solution of the present invention and the corresponding DC / DC conversion method.

[0092] Such as Figure 5 As shown, the converter includes a power switch PMOS, an inductor L 0 , voltage divider circuit and bandgap reference source Bandgap;

[0093] Among them, the voltage divider circuit is mainly composed of resistors RFB1 and RFB2, and the voltage divider is obtained with V OUT proportional to the feedback voltage V FB ;

[0094] Additionally, the converter includes:

[0095] The current detection module ISENSE is respectively connected to the power switch PMOS and the inductor L 0 , for generating a current detection signal reflecting the magnitude of the current flowing through the power switch PMOS;

[0096] The oscillator OSC is connected to the current detection module ISENSE, and is used to superimpose and compensate the current detection signal to g...

Embodiment 2

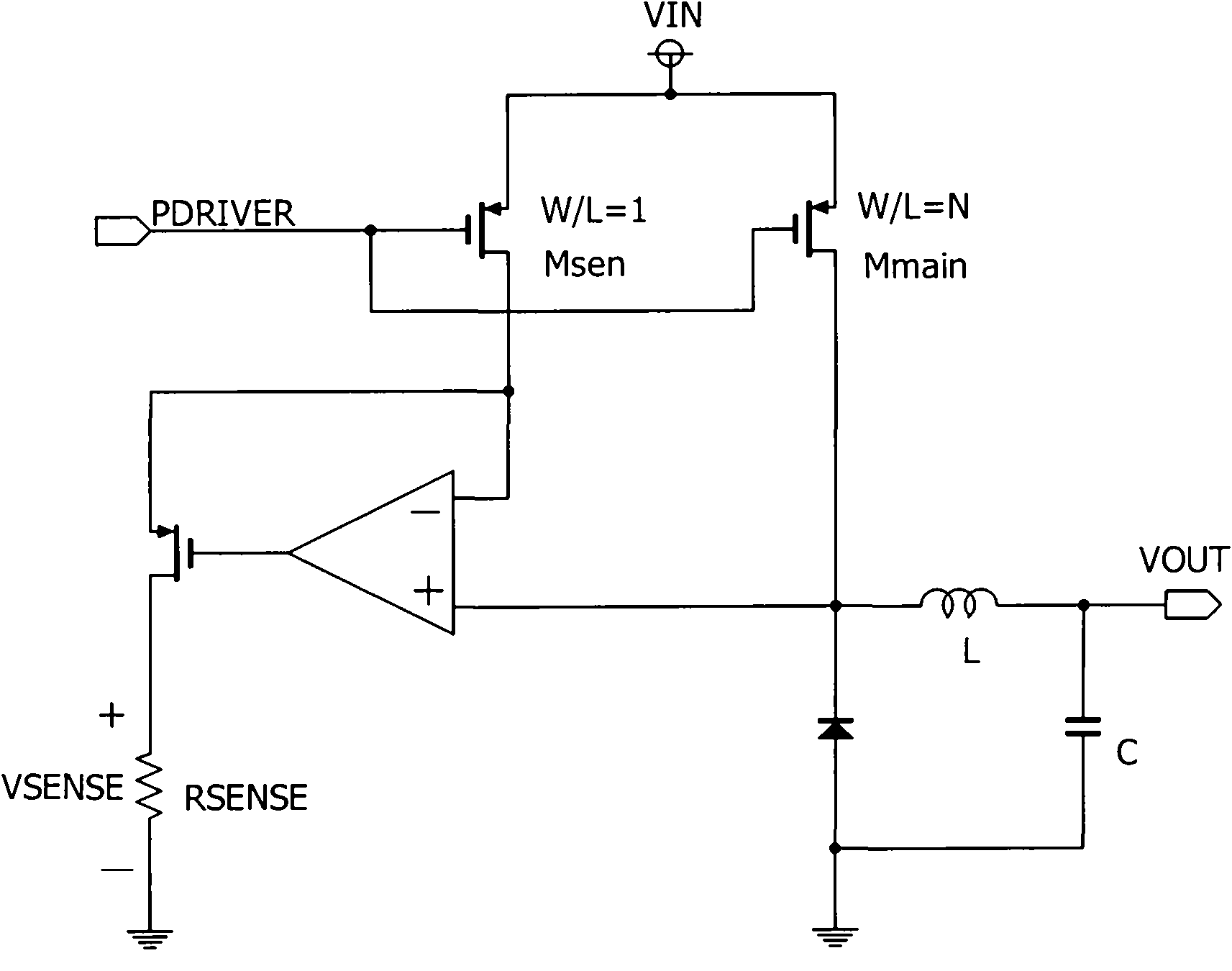

[0108] This embodiment takes a step-down DC / DC converter as an example to describe the specific structure and corresponding working process of the current detection module ISENSE and the oscillator OSC contained in the converter.

[0109] Such as Image 6 As shown, the current detection module ISENSE includes an amplification unit A, a feedback capacitor C 1 , input capacitance C 2 and the first S 1 , the second S 2 , the third S 3 switch;

[0110] The first switch S 1 used to control whether the feedback capacitor is connected to the circuit;

[0111] The second switch S 2 Used to control whether the source of the power switch is connected to the circuit;

[0112] The third switch S 3 used to control whether the current detection module is connected to the drain of the power switch;

[0113] The amplifying unit A is used to amplify the difference between the power switch drain voltage and the source voltage, and then generate a current detection signal for reflectin...

Embodiment 3

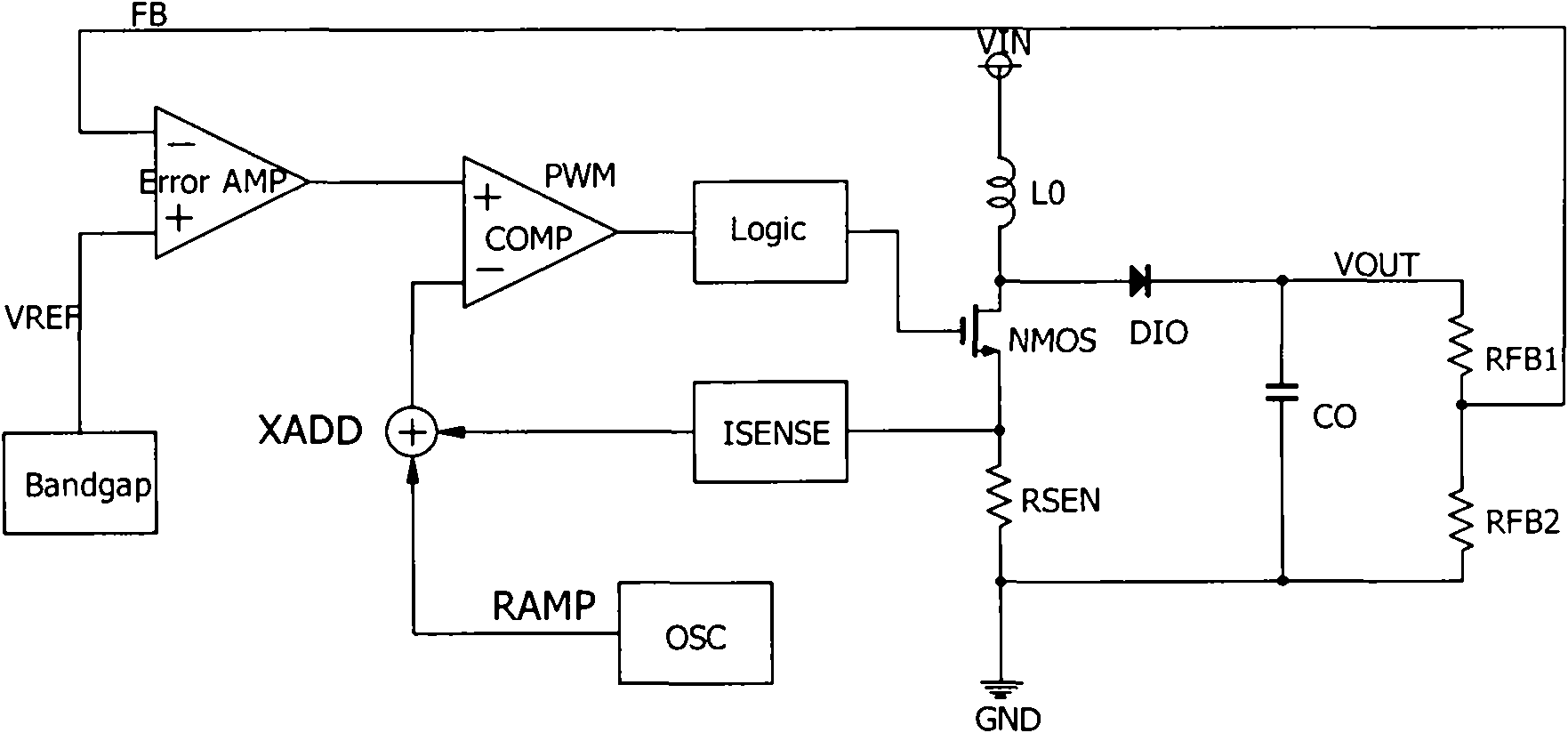

[0147]This embodiment takes a step-up DC / DC converter as an example to describe the specific structure and corresponding working process of the current detection module ISENSE and the oscillator OSC included in the converter.

[0148] Such as Figure 8 As shown, the current detection module ISENSE includes an amplification unit A, a feedback capacitor C 1 , input capacitance C 2 and the first S 1 , the second S 2 , the third S 3 switch;

[0149] The first switch S 1 used to control whether the feedback capacitor is connected to the circuit;

[0150] The second switch S 2 Used to control whether the source of the power switch is connected to the circuit;

[0151] The third switch S 3 used to control whether the current detection module is connected to the drain of the power switch;

[0152] The amplifying unit A is used to amplify the difference between the power switch drain voltage and the source voltage, and then generate a current detection signal for reflecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com