Sanguisorba saponins and preparation method of sanguisorbin I

A technology of total saponins and Burnet, applied in the field of medicine, achieves the effect of reducing cost, high enrichment and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

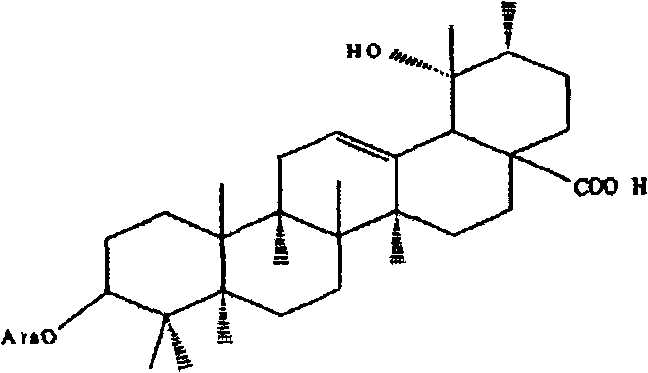

Image

Examples

Embodiment 1

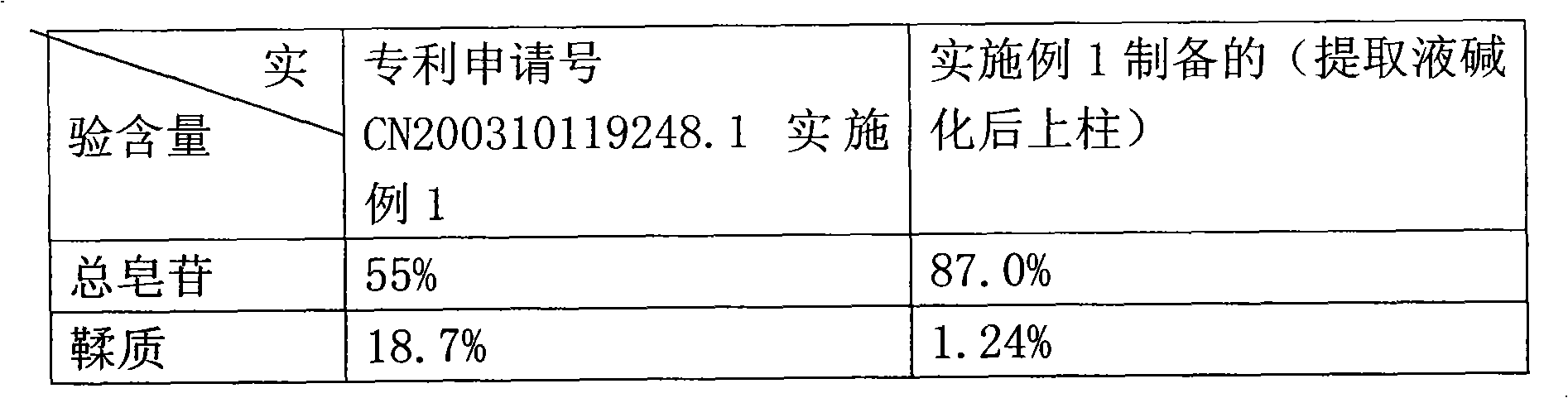

[0029] Embodiment 1: the preparation of total saponins of Burnet burnet

[0030] Burnet decoction pieces 30kg, add 240L of 30% ethanol and extract under reflux for 1h, filter the residue with 180L of 30% ethanol and extract under reflux for 1h, combine the filtrate, add 600L of water to dilute, add sodium hydroxide solution (3.5kg of sodium hydroxide dissolved in 24L water), adjust the pH value to 14.2, let stand, centrifuge to obtain the filtrate, pass through the D101 type macroporous adsorption resin, the flow rate is 1.5 column volume / h, and use 4 column volumes of 30% ethanol to elute after finishing the drug solution, and then Then eluted with water until the effluent was colorless, and finally eluted with 70% ethanol of 3 times the volume of the column bed, collected the 70% ethanol effluent, concentrated in vacuo until a certain amount of substance was precipitated, then stopped concentrating, stood for more than 2 hours, and reduced Suction pressure filtration, wash w...

Embodiment 2

[0031] Embodiment 2: the preparation of total saponins of Burnet burnet

[0032] Burnet decoction pieces 30kg, add 300L of 60% ethanol and heat under reflux to extract for 1h, filter to obtain the filtrate, add 450L of water to dilute, add potassium hydroxide solution (2.5kg of sodium hydroxide dissolved in 25L of water) under stirring to adjust the pH value to 10.5, static place, centrifuge to obtain the filtrate, pass through the macroporous adsorption resin HPD100, the flow rate is 1.2 column volume / h, and then wash with water until the effluent is colorless, then use 4 times the volume of the column bed for elution, and collect the acetone The eluent was concentrated in vacuo, dried in a vacuum oven, and pulverized to obtain 1.09 kg of total glycosides of Burnet glucosides powder, with a yield of 3.63%. The content of total saponins of Burnet eucalyptus was 71% as detected by colorimetry, and it was detected by high performance liquid chromatography. The content of elm sap...

Embodiment 3

[0033] Embodiment 3: the preparation of total saponins of Burnet burnet

[0034] Burnet decoction pieces 30kg, add 240L of 45% ethanol and extract under reflux for 1h, then filter the residue with 180L of 30% ethanol and extract under reflux for 1h, combine the filtrate, add 600L of water to dilute, add calcium hydroxide suspension (3kg of calcium hydroxide suspended in 30L water) adjust the pH value to 14, let it stand, filter to obtain the filtrate, pass through the macroporous adsorption resin D101, the flow rate is 1.8 column volume / h, and then use 4 column volumes of 1.0% sodium hydroxide solution to elute , then eluted with water until the effluent was colorless, then eluted with 30% ethanol of 3 times the volume of the column bed, and finally eluted with 75% ethanol of 3 times the volume of the column bed, collected the 75% ethanol eluate, and concentrated in vacuo , until there is no alcohol smell, the remaining concentrate is dried in a vacuum oven and pulverized to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com