Preparation method for nickel-cobalt-manganese ternary hydroxide for lithium battery and product

A hydroxide, nickel cobalt manganese technology, applied in nickel oxide/nickel hydroxide, electrical components, battery electrodes, etc., can solve the problem of unstable physical and chemical properties, electrochemical performance and quality indicators, poor operation controllability, and high energy consumption problems, to achieve the effects of improving electrochemical properties, uniform inlay and out, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

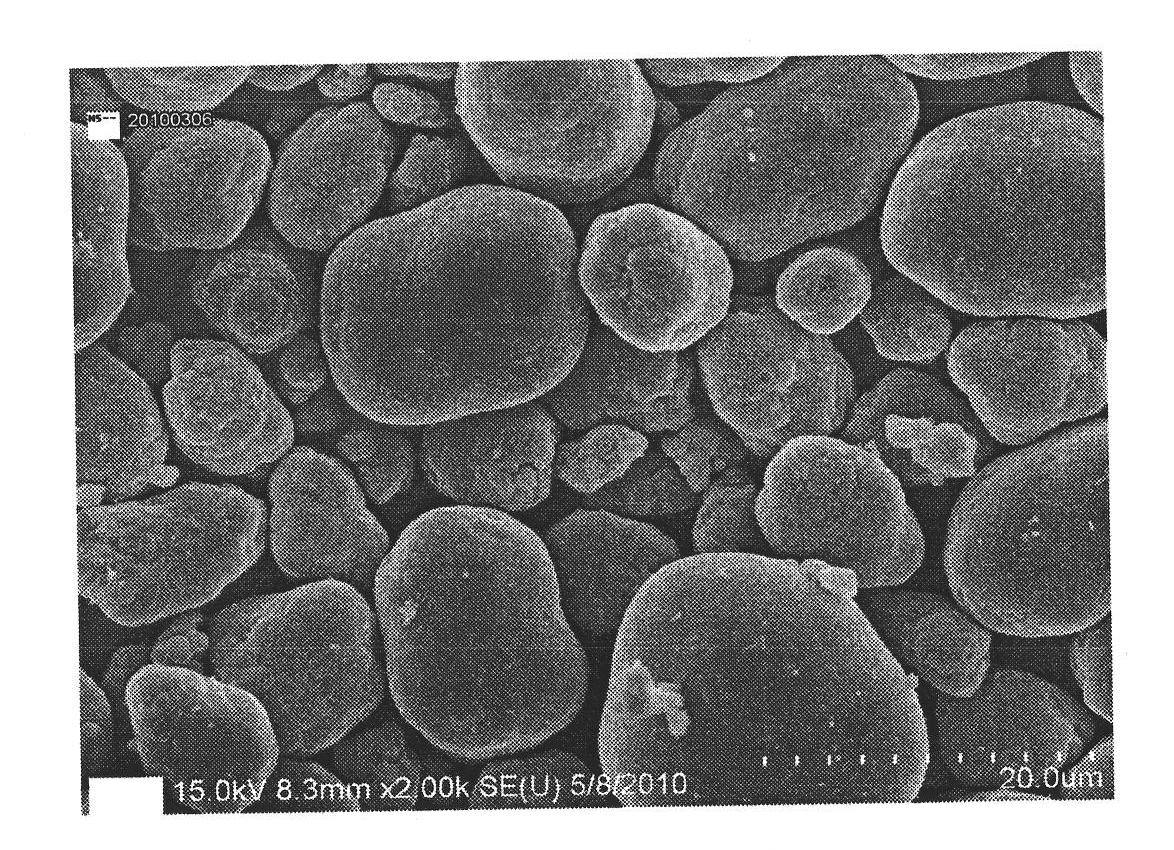

Embodiment 1

[0024] Add 112g of nickel chloride, 108g of cobalt chloride and 57g of manganese chloride to 1330ml of water, mix well, add 0.8g of oxalic acid (H 2 C 2 O 4 ) Stir for 2 hours, then modify and purify in a tubular reactor with a magnetic flux of 900 Stella to make liquid A, and modify the sodium hydroxide in a tubular reactor with a magnetic flux of 850 Stella. Purify into material liquid B; disperse material liquid A at a speed of 1.5 liters / hour and material liquid B at a speed of 0.8 liters / hour into the non-magnetic reactor, in the liquid phase with both axial flow and radial flow In the environment, the reaction temperature is controlled at 50℃, and the pH is 9.5 to 10.0. The nickel, cobalt, and manganese ions are co-precipitated through the affinity of the hydroxyl bond. A spherical nickel-cobalt-manganese ternary hydroxide and inorganic salt mixture slurry with a diameter of 9 microns. The slurry removes inorganic salts and stabilizers in a water system at 85°C to obtain a...

Embodiment 2

[0026] In 4000ml of water, add 636g of nickel sulfate, 257g of cobalt sulfate and 227g of manganese sulfate, mix well, add 5.8g of oxalic acid (H 2 C 2 O 4 ) Stir for 3 hours, then modify and purify in a tubular reactor with a magnetic flux of 350 Stella to make liquid A, and sodium hydroxide is modified and purified in a tubular reactor with a magnetic flux of 350 Stella The feed liquid B is prepared, and the feed liquid A is dispersed into the non-magnetic reactor at a speed of 1.8 liters / hour and the feed liquid B is dispersed into the non-magnetic reactor at a speed of 0.85 liters / hour, in a liquid phase environment with both axial flow and radial flow. The reaction temperature was controlled at 60°C and the pH was 9.5 to 10.0. The nickel, cobalt, and manganese ions were co-precipitated through the affinity of the hydroxyl bond. After the affinity co-precipitation, they were reconstructed and modified in a laminar flow in a natural state, and the average particle size was A ...

Embodiment 3

[0028] In 1900ml water, add 280g nickel nitrate, 270g cobalt nitrate and 113g manganese nitrate respectively, mix well, add 4.0g oxalic acid (H 2 C 2 O 4 ) Stir for 1.5 hours, then modify and purify in a tubular reactor with a magnetic flux of 950 Stella to make feed liquid A, and sodium hydroxide is modified and purified in a tubular reactor with a magnetic flux of 650 Stella Prepare feed liquid B, feed liquid A at a speed of 2.0 liters / hour, and feed liquid B at a speed of 1.0 liters / hour into the non-magnetic reaction kettle, in a liquid phase environment with both axial flow and radial flow The reaction temperature was controlled at 70℃ and the pH value was 10~11.5. The nickel, cobalt, and manganese ions were co-precipitated through the affinity of the hydroxyl bond. After the affinity co-precipitation, they were reconstructed and modified in a laminar flow in a natural state to obtain an average particle size 10 micron spherical nickel-cobalt-manganese ternary hydroxide and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com