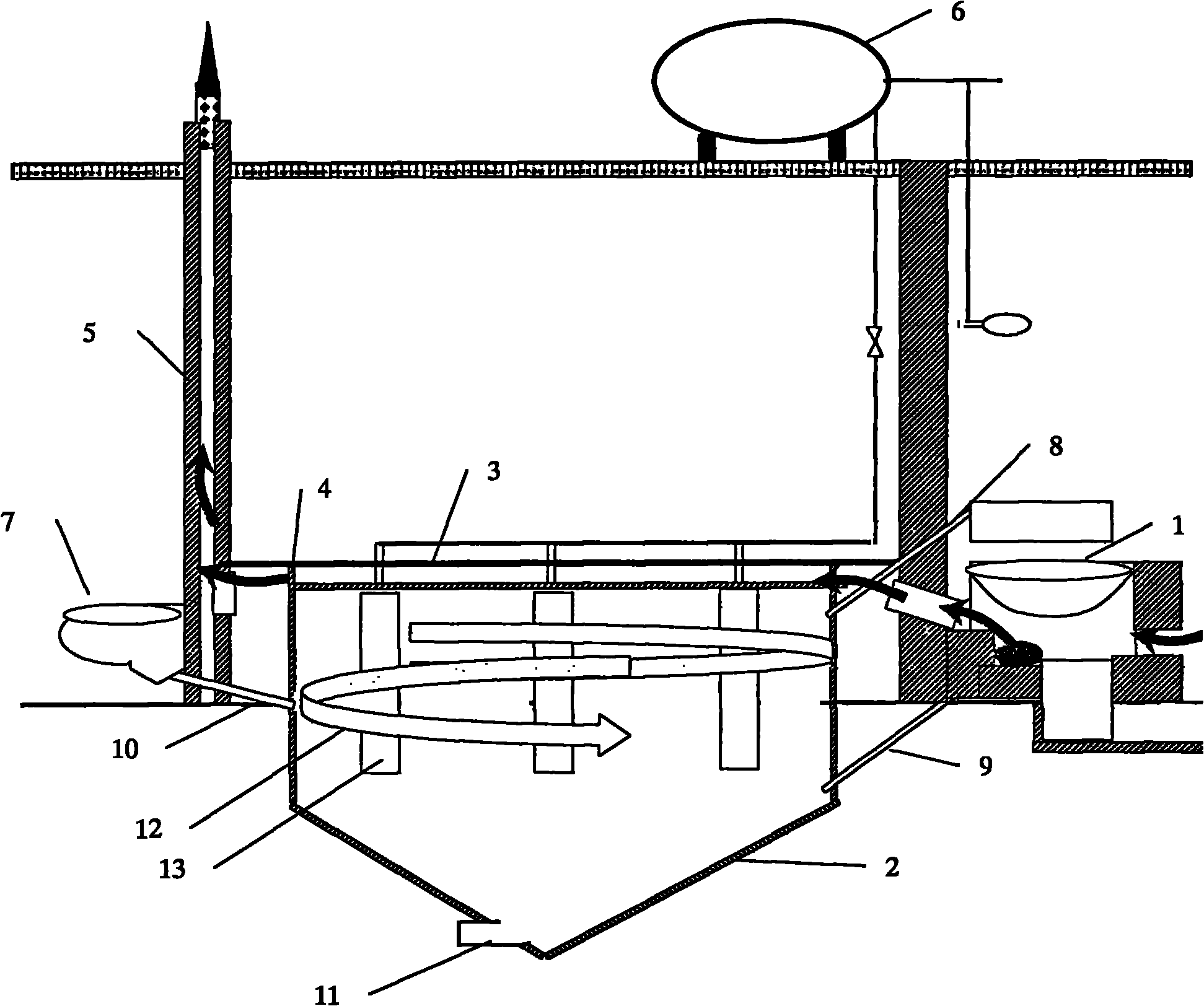

Pool-stove-kang-kitchen-toilet five-in-one biogas production method for rural houses in cold areas

A five-in-one technology in cold regions, applied in biological sludge treatment, gas/liquid distribution and storage, waste fuel, etc. Conducive to continuous fermentation operation and the effect of increasing gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As shown in the accompanying drawings, the fermentation reaction pool (2) is built directly below the heated kang, adopts masonry reinforced concrete materials, is surrounded by building foundation wall insulation, and the top is heated by stove (1) flue gas. During the cooking process, while heating the kang, the hot flue gas flows through the inside of the kang to increase the temperature and heat the fermentation reaction tank downwards. With the antifreeze and heat preservation effect of the foundation of the house, the water temperature in the reaction chamber reaches the temperature required for fermentation. The biogas tank side wall extends upwards as a heated kang support column (4) to support the upper heated kang surface (3), and the heated kang surface (3) is made of prefabricated slab reinforced concrete.

[0017] After the flue gas passes through the kang heating chamber and the biogas reaction tank, it is discharged through the chimney along the smoke wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com