Manufacture method of tilted fiber grating hydrogen sensor based on optical catalytic oxidation

A technology of inclined fiber grating and photocatalytic oxidation, which is applied in the measurement of phase influence characteristics, etc., to solve the poisoning of hydrogen-sensitive catalysts, improve the sensitivity, and make it easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

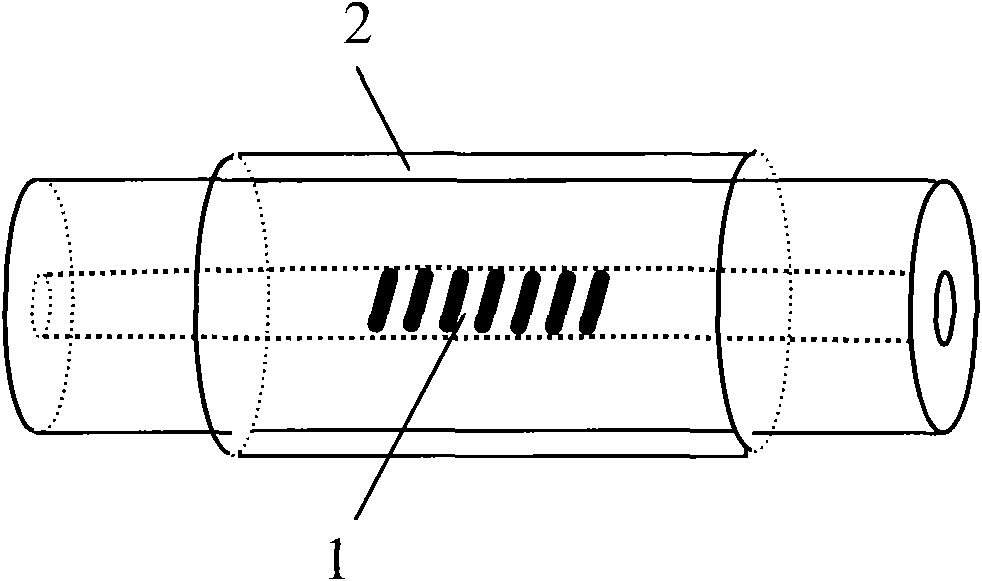

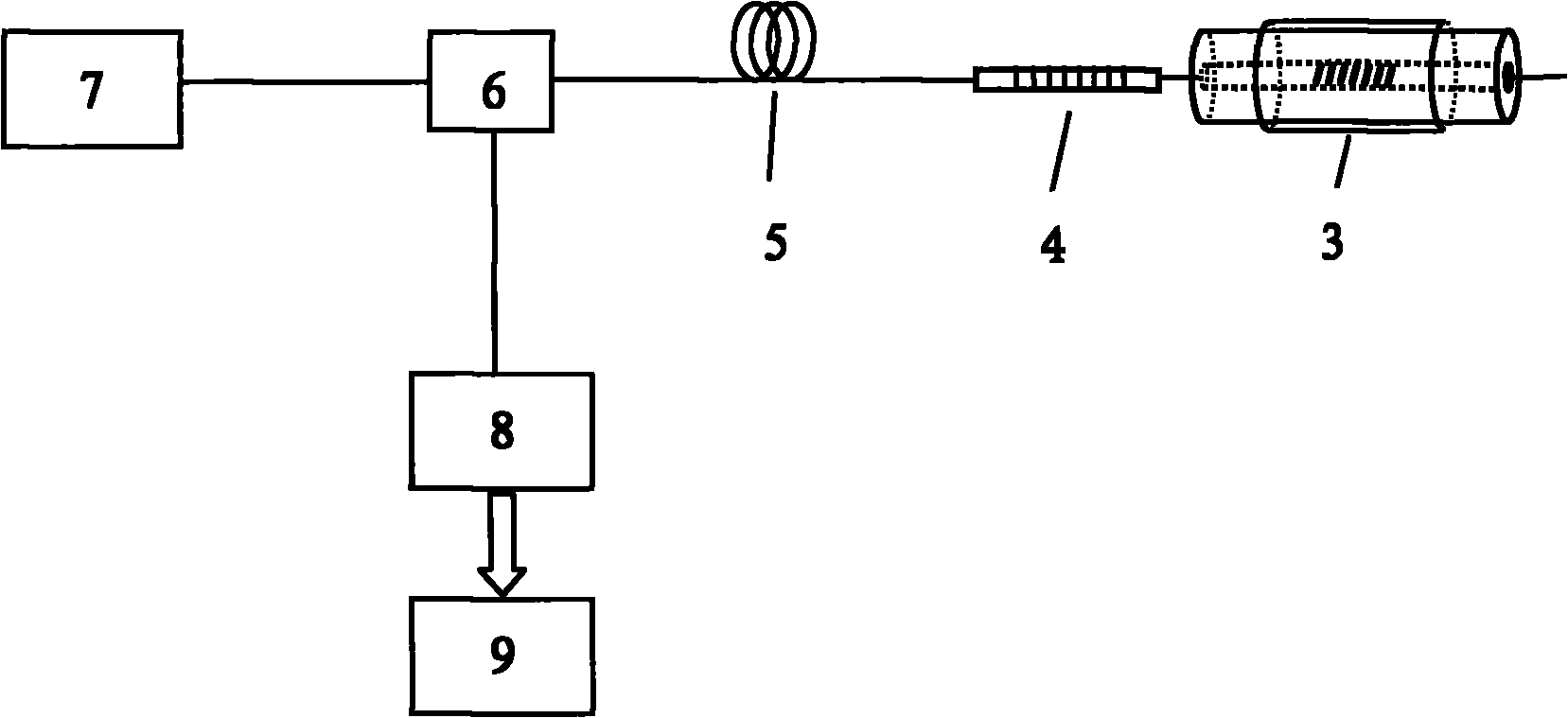

[0012] Example 1. First prepare sol-gel tungstic acid with protonated cation exchange resin with sodium tungstate, wash the prepared tungstic acid with deionized water and centrifuge 3 times; heat to 50°C and let stand for 5 hour, make it dry into powder; then add platinum chloric acid, stir and heat to 400°C, let it stand for 1 hour to obtain platinum-doped tungsten oxide powder whose surface is adsorbed by platinum, wherein the molar ratio of platinum to tungsten is 1:14; Finally, the platinum-doped tungsten oxide powder is added to the ethanolamine solvent, and then it is uniformly deposited on the surface of the inclined fiber grating by dipping and coating to form a hydrogen sensitive film.

Embodiment 2

[0013] Example 2. First prepare sol-gel tungstic acid with protonated cation exchange resin with sodium tungstate, wash the prepared tungstic acid with deionized water and centrifuge 5 times; hour, make it dry into powder; then add platinum chloric acid, stir and heat to 450°C, let it stand for 1.5 hours to obtain platinum-doped tungsten oxide powder whose surface is adsorbed by platinum, wherein the molar ratio of platinum to tungsten is 1:14; Finally, the platinum-doped tungsten oxide powder is added to the ethanolamine solvent, and then it is uniformly deposited on the surface of the inclined fiber grating by dipping and coating to form a hydrogen sensitive film.

Embodiment 3

[0014] Example 3. First, sol-gel tungstic acid was prepared with protonated cation exchange resin with sodium tungstate, and the prepared tungstic acid was washed with deionized water and centrifuged 8 times; heated to 60°C, and stood for 7 hour, make it dry into powder; then add platinum chloric acid, stir and heat to 500°C, let it stand for 2 hours to obtain platinum-doped tungsten oxide powder whose surface is adsorbed by platinum, wherein the molar ratio of platinum to tungsten is 1:14; Finally, the platinum-doped tungsten oxide powder was added to the ethanolamine solvent, and then it was uniformly deposited on the surface of the inclined fiber grating by dip coating to form a hydrogen sensitive film.

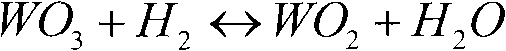

[0015] Platinum-doped tungsten oxide films were prepared on the surface of inclined gratings by sol-gel method. When hydrogen exists, the tungsten oxide film will produce the following chemical reactions:

[0016]

[0017]

[0018] When tungsten trioxide is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com