Biosynthesis of cocoa butter improver

A technology of stearic acid and fatty acid, which is applied in the field of biosynthesis of cocoa butter improver, can solve the problems of high SOS content and low value, and achieve the effect of increasing solid fat content and enhancing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1. The transesterification reaction of raw material

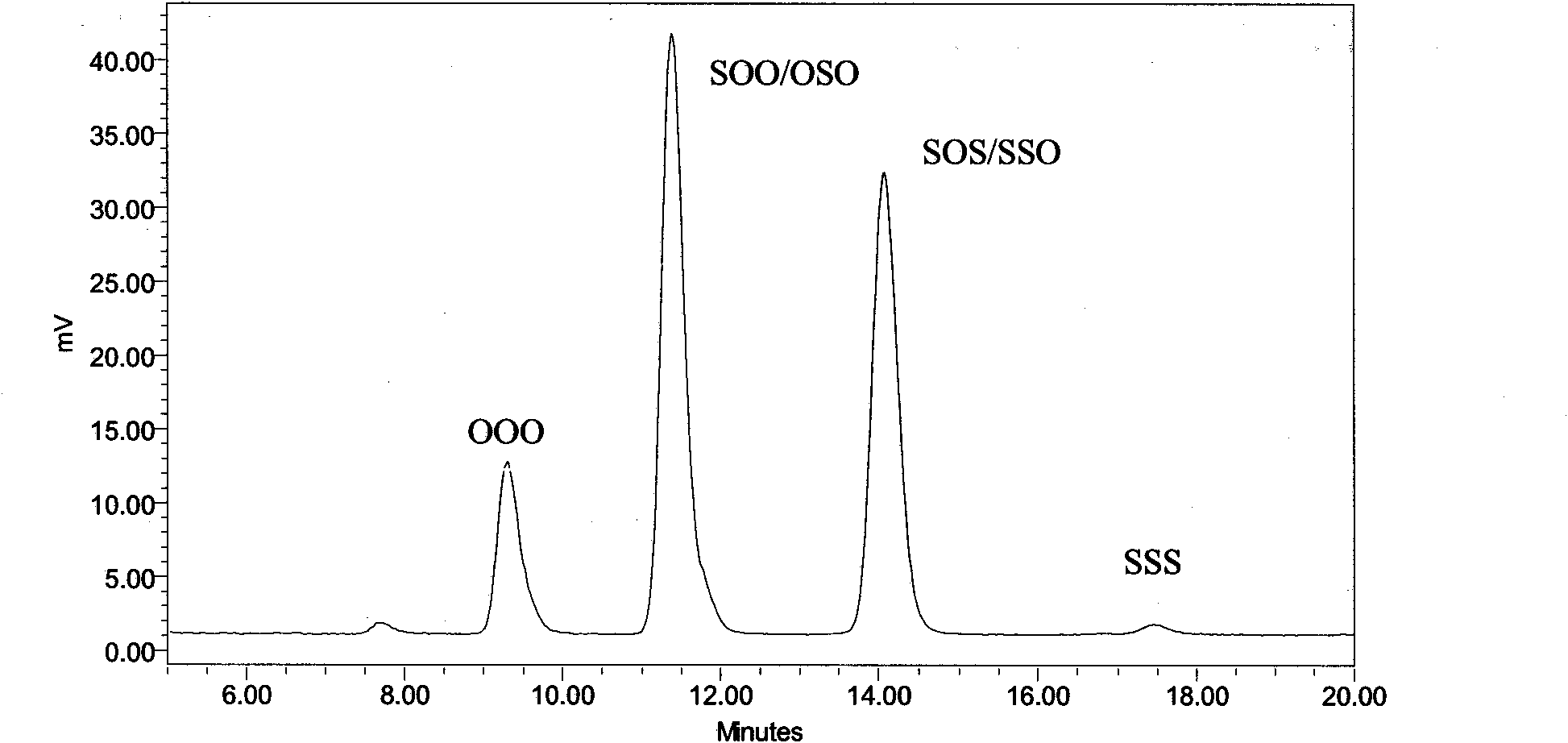

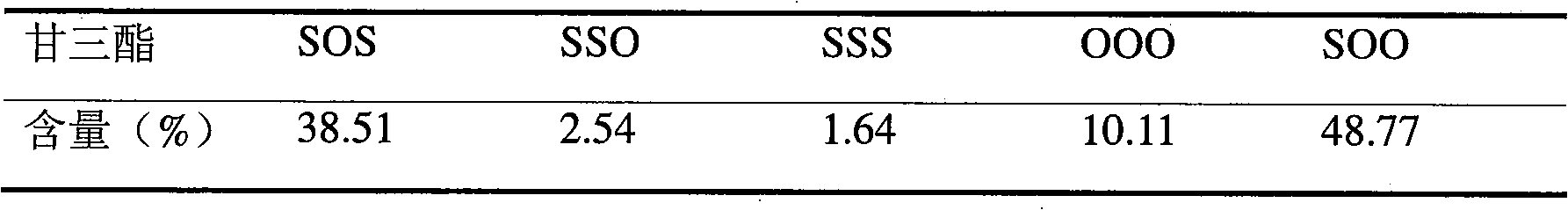

[0020] Accurately weigh a mixture of high oleic vegetable oil / stearic acid with a molar ratio of 1:4, and react at 70°C for 4 hours with 1% water and 10% enzyme. The main triglyceride composition in the reaction product is shown in Table 1.

[0021] Main triglyceride composition in the reaction product of table 1

[0022]

Embodiment 2

[0023] Embodiment 2. Deacidification by molecular distillation

[0024] Weigh 200g of the product after transesterification, the yield of the heavy phase obtained at a preheating temperature of 80°C, a feed rate of 2mL / min, a heating wall temperature of 190°C, and a scraper speed of 120r / min is about 44%, and the acid value of the heavy phase Since 115.8mgKOH / g is lower than 3.1, the acid value of the heavy phase obtained by the first-stage molecular distillation is less than 0.28mgKOH / g after the second-stage molecular distillation is carried out under the same conditions. Wherein the light phase containing a large amount of stearic acid can be directly or extremely hydrogenated and recycled as raw material for transesterification.

Embodiment 3

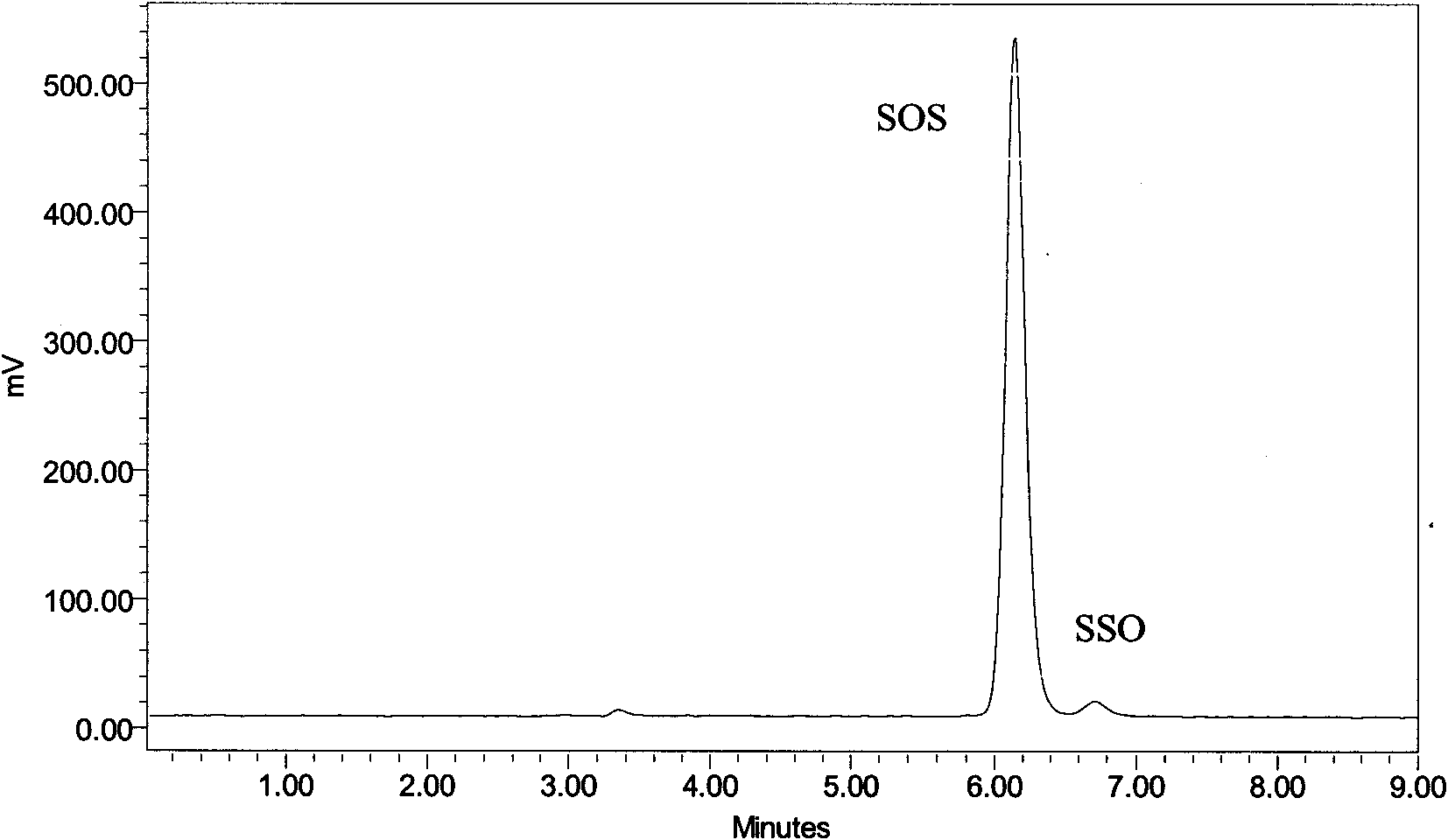

[0025] Embodiment 3. Fractionation and purification

[0026] Weigh 10 g of the deacidification product prepared in Example 2, add 20 mL of acetone 1:2, melt completely in a water bath at 50°C, then crystallize to remove diacylglycerol, and then keep it at 20°C for 4 hours to precipitate part of the crystals , the crystals are suction filtered and the solvent is air-dried to obtain about 2.45 g of stearin with an SOS content of 73.6%, wherein low-melting palmitin (mainly composed of SOO and OOO) is recycled as a transesterification raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com