Soft tissue engineering scaffold and preparation process thereof

A tissue engineering scaffold and film technology, applied in medical science, muscle, ligament and other directions, can solve the problems of poor controllability, complex, difficult to build structures, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

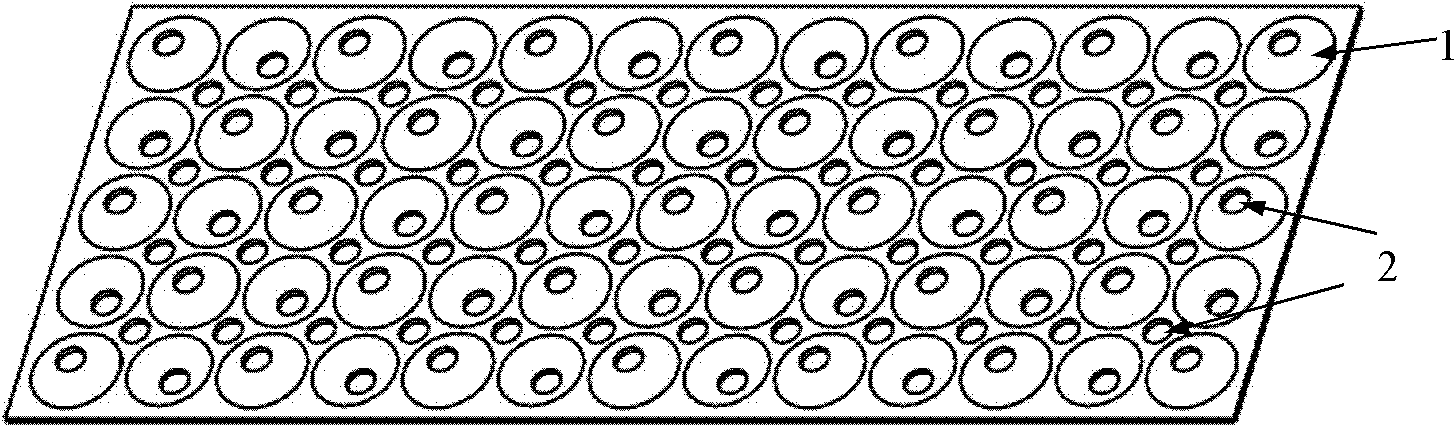

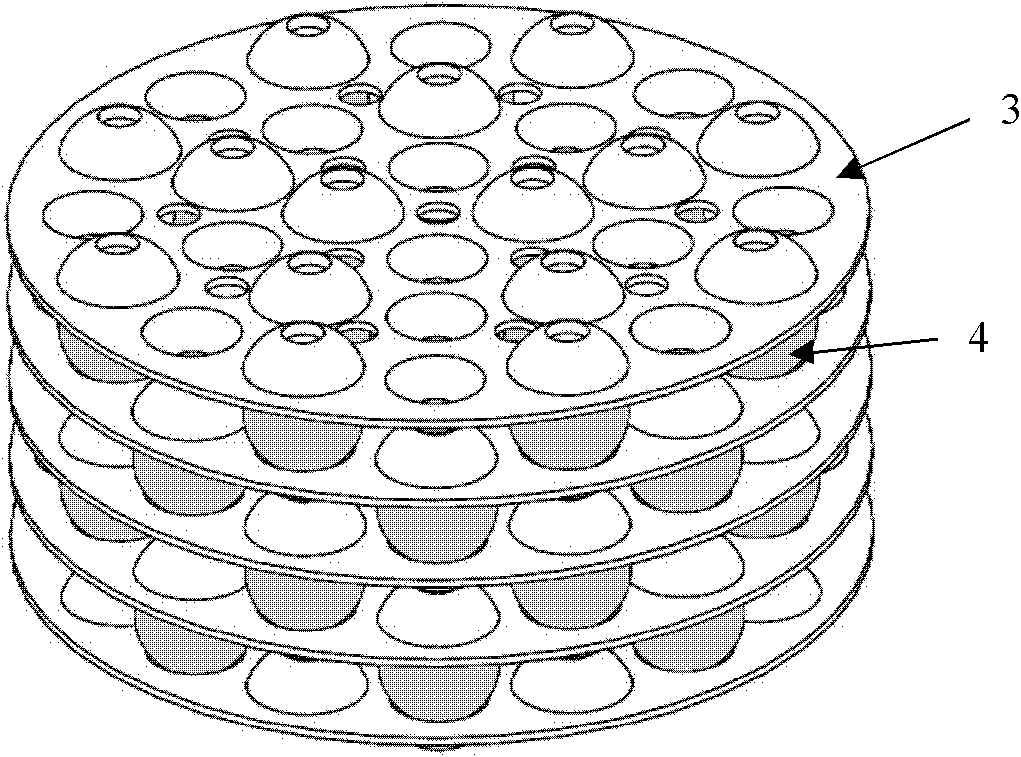

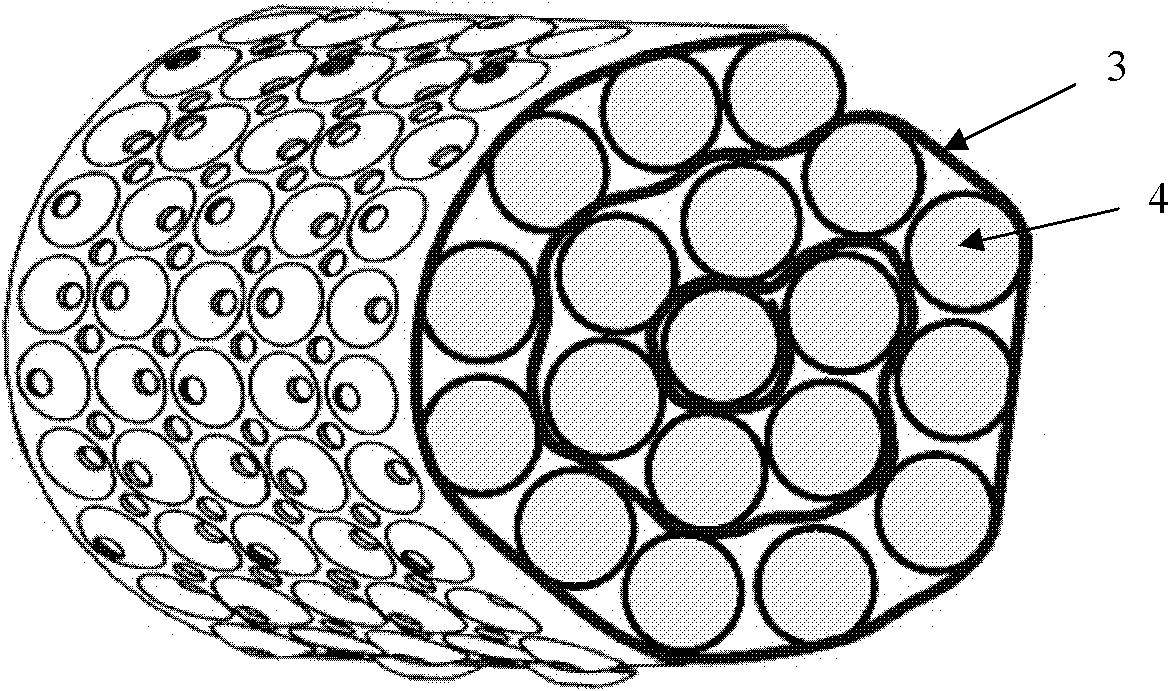

[0022] A soft tissue engineering scaffold, the visceral soft tissue engineering scaffold is formed by crimping or stacking small balls and thin films.

[0023] The pellets are made of biological materials (such as chitosan, silk fibroin, collagen, hydrogel, polylactic acid or polylactic acid-polyglycolic acid, heparin, cells, growth factors, and other anticoagulants), and can also be made of These biomaterials are mixed with cells; the pellets can be made by hand or pressed through molds;

[0024] The film is composed of biological materials (such as silk fibroin, chitosan, collagen, hydrogel, polylactic acid or polylactic acid-polyglycolic acid, heparin, and other anticoagulants), and can also be formed from these biological materials. Mix with cells and growth factors by infiltration. The material of the film must have a certain degree of elasticity and toughness, which is convenient for forming and maintaining the shape of the stent.

[0025] There are two types of films:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com