Micro-fluidic chip for micro-magnetic field control and manufacturing method thereof

A technology of microfluidic control and microfluidic device, which is applied in the field of microfluidic chip controlled by micromagnetic field and its production, can solve the problems of difficult observation and high requirements for instruments and equipment, and achieve the effect of avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

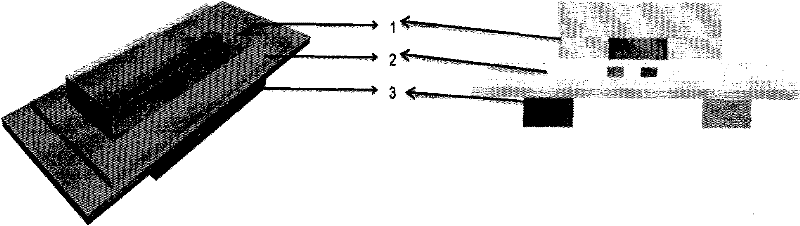

[0031] 1. Production:

[0032] (1) Cut the ITO conductive glass into a size of 30mm x 80mm, ultrasonically clean it in ethanol and ultrapure water, and then apply a layer of AZ4620 photoresist with a height of about 12 μm, pass through a printed mask, UV exposure is carried out under the machine to form the same pattern as on the mask. Then, in the electroplating bath, using a DC power supply and a large piece of nickel, electroplating is performed, and then the photoresist is removed in acetone, so that a tiny pattern of nickel is formed on the ITO conductive glass. Then adjust a polydimethylsiloxane (PDMS) prepolymer with a mass ratio of 15:1 (RTV615A:B), remove air bubbles in a vacuum, and use a plastic throwing machine to throw out a polydimethylsiloxane (PDMS) prepolymer of about The PDMS layer with a thickness of 8 μm was cured in an oven for half an hour. This encapsulates the nickel micropatterns in PDMS, avoids contact with magnetic beads in subsequent experiments, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com