Nanocrystalline wood floor geothermal composite structure

A nano-microcrystalline and composite structure technology, applied in heating methods, electric heating systems, household heating, etc., can solve problems such as waste of water resources, complicated installation work, waste of resources, etc., to enhance dimensional stability, alleviate peak-valley electricity consumption, etc. Contradictions, the effect of strengthening the heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

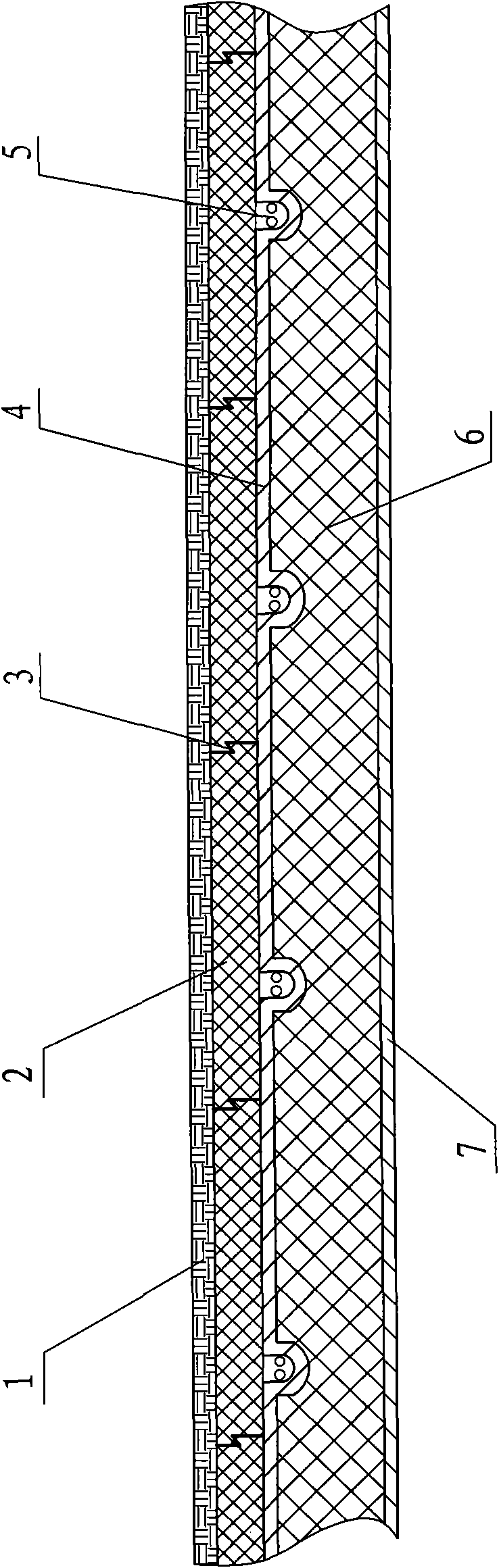

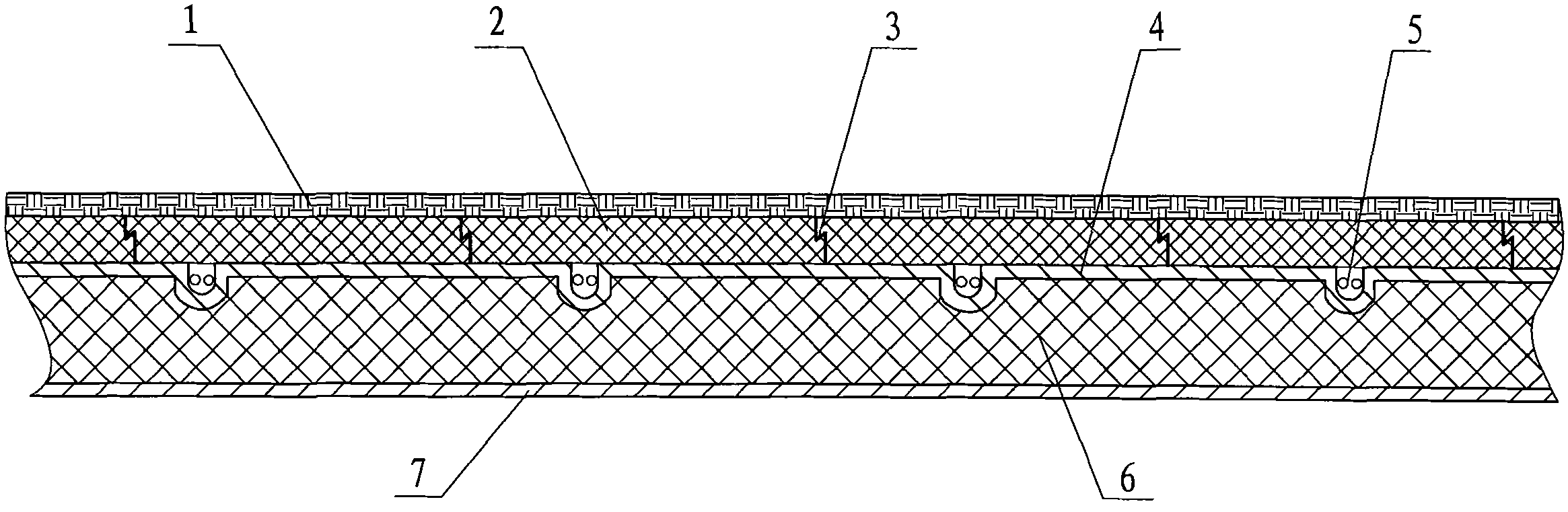

[0027] Depend on figure 1 As shown, 2 in the figure is the nano-microcrystalline wood floor layer, 6 is the XPS extruded board heat insulation layer, and a closed groove is evenly opened on the upper part of the XPS extruded board heat insulation layer 6, and the XPS extruded board heat insulation layer is evenly opened. The upper part of the heat layer 6 and the closed groove part are evenly distributed with an aluminum heat-conducting layer 4, and the bending part of the closed groove is an arc-shaped groove; the closed groove with the aluminum heat-conducting layer 4 is covered with silica gel Heating cable 5, the silicone heating cable 5 is connected to the power supply through a temperature control switch with a temperature sensor; a nano-microcrystalline wood floor layer 2 with a wear-resistant surface layer 1 is directly laid on the top of the heat conduction layer. In addition, a metal heat reflection layer 7 is directly laid on the lower part of the XPS extruded board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com