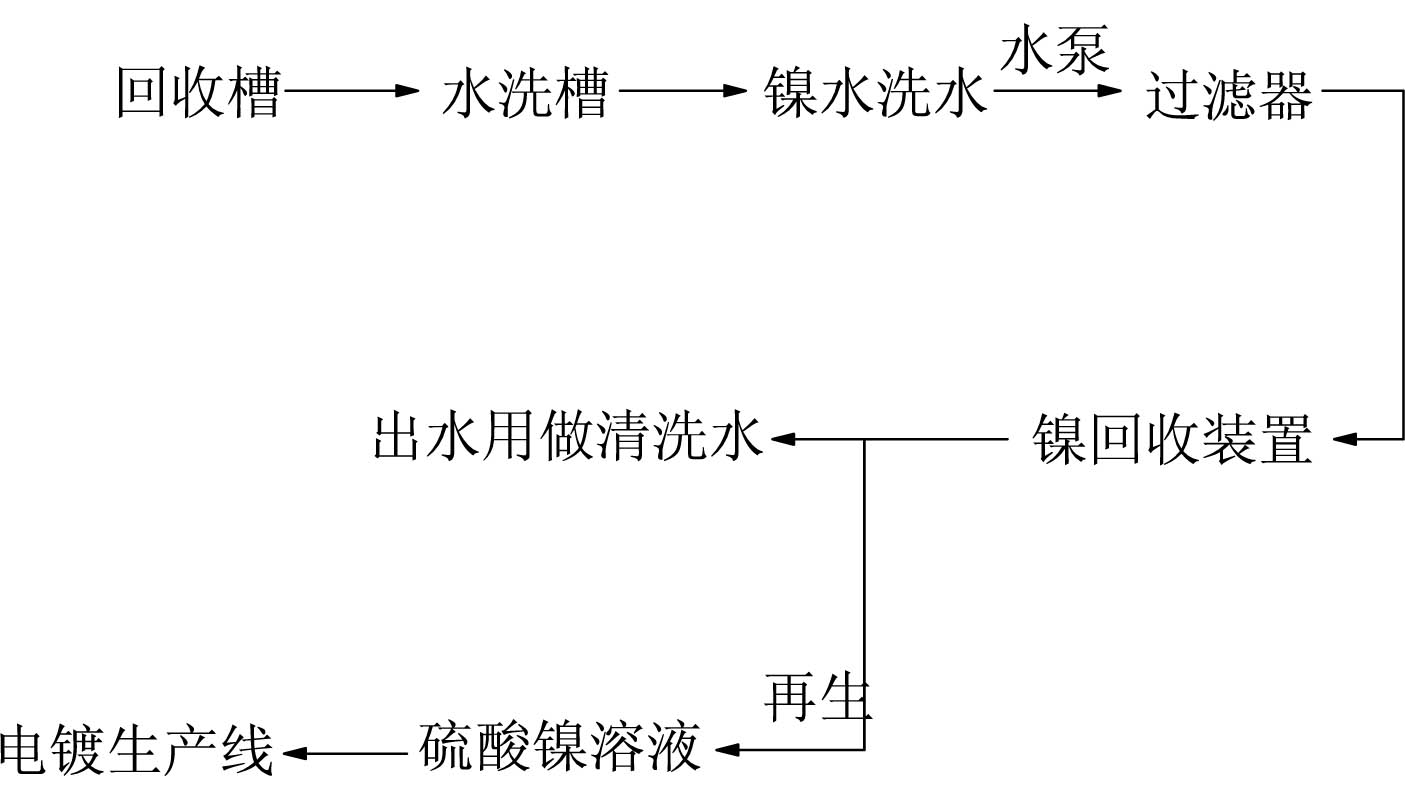

Method and device for recovering nickel resource and water resource in nickel plating wastewater

A recovery device and recovery method technology, applied in metallurgical wastewater treatment, ion-exchange water/sewage treatment, nickel sulfate, etc., can solve problems such as affecting the ion-exchange efficiency and nickel resource purity, and achieve burden reduction, high purity, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

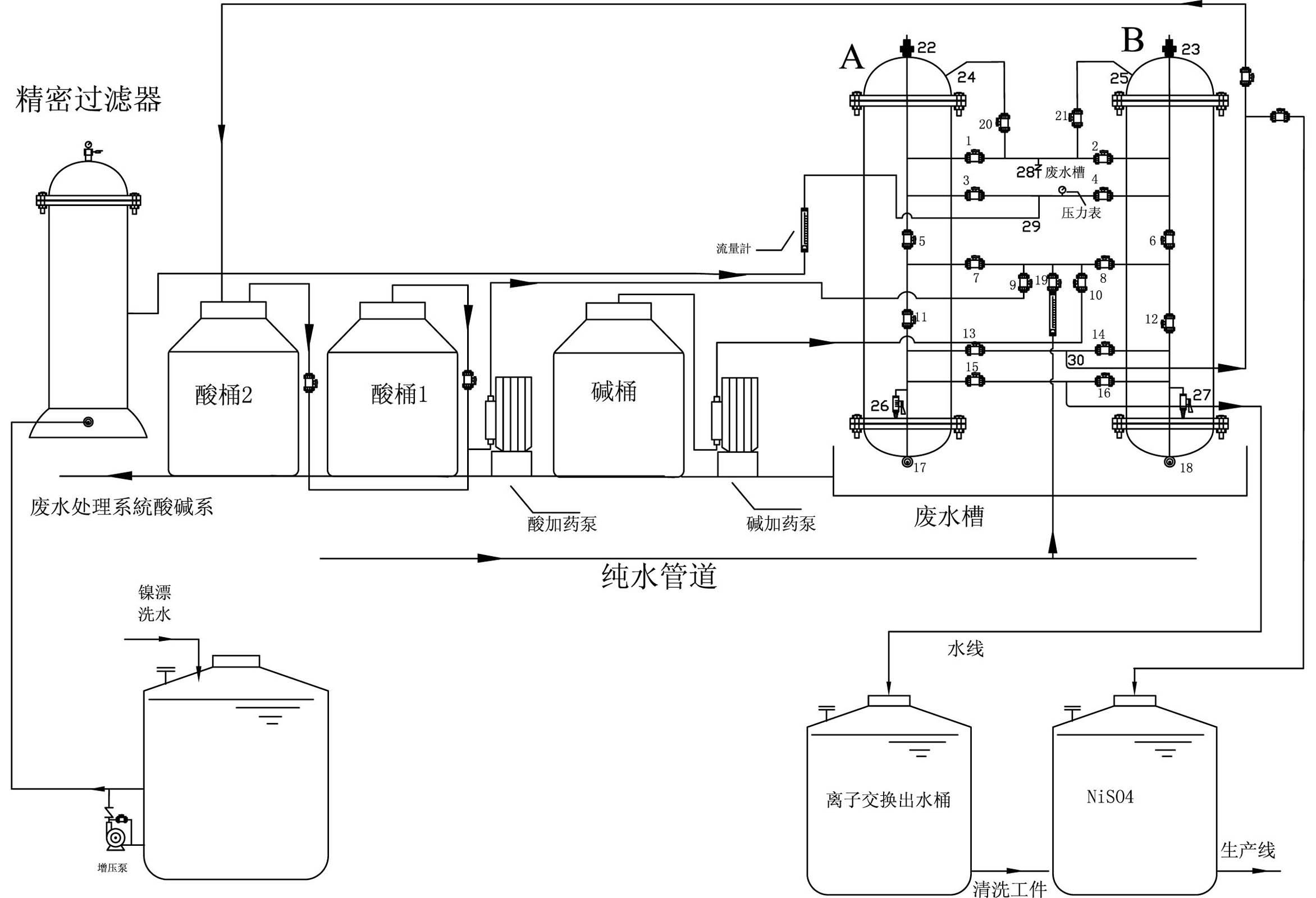

[0040] Example 1: Nickel plating rinsing water contains 419 mg / l of nickel, pumped into the nickel resource recovery device, nickel ions are ion-exchanged with the nickel high-selectivity resin, nickel resources are adsorbed on the nickel high-selectivity resin, use 10-15% Sulfuric acid washes down the nickel resources, and the resin is regenerated with 1.5mol / l sodium hydroxide. The eluent contains 66g / l of nickel, and the exchanged water contains 0.11mg / l of nickel.

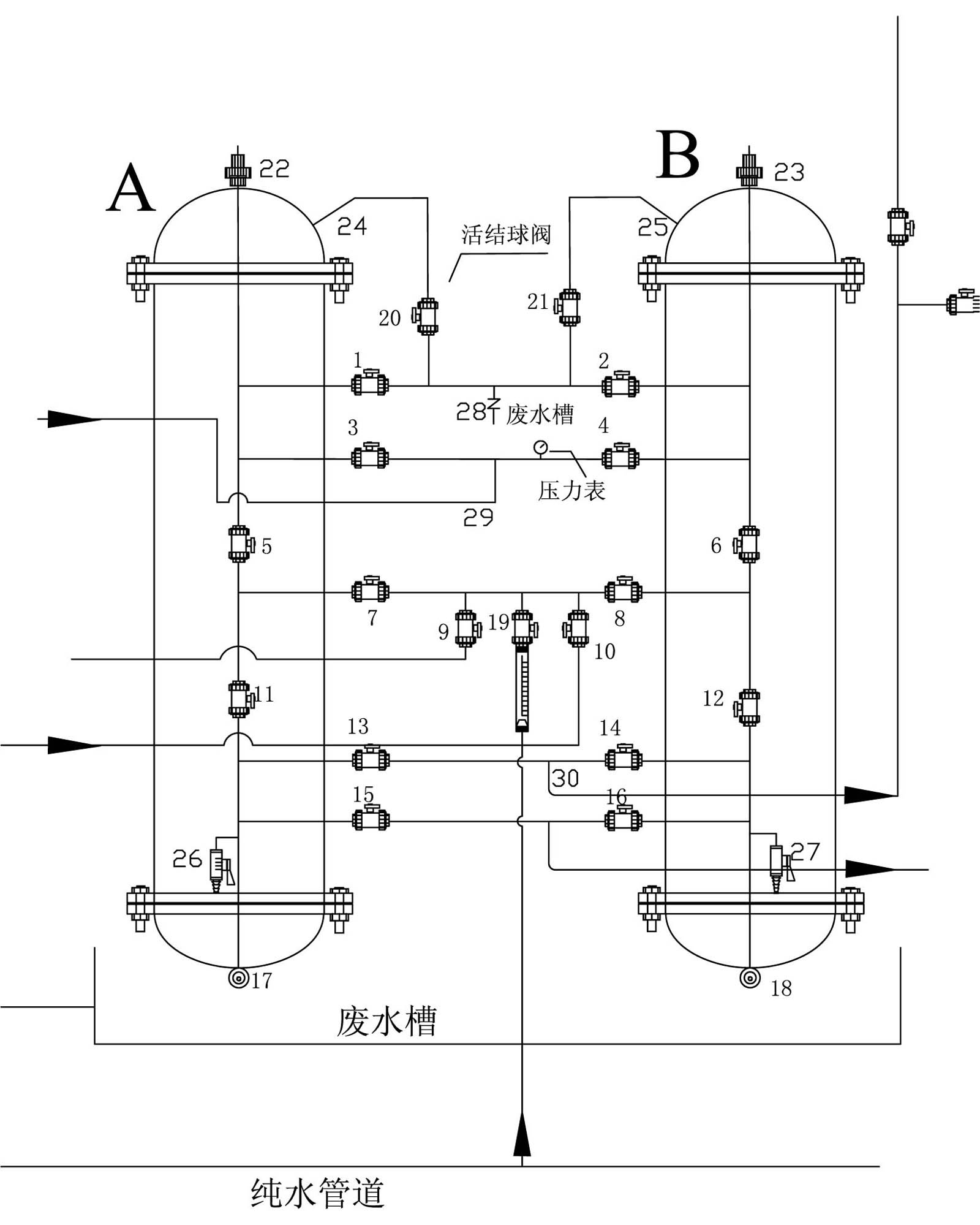

[0041] The operating principle of the nickel-plating waste water nickel resource and water resource recovery device of the present invention, with reference to the appended figure 2 , image 3 shown;

[0042] 1. Before production, all pumps are turned on automatically, and all valves are closed.

[0043] 2. Container A and container B are used in series, container A→container B

[0044] First open the valves 3, 11, 7, 8, 6, 16, pump the nickel rinsing water to the nickel recovery device, the nickel water en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com