Separation and purification method for cerebroside and ceramide type compound

A technology for the separation and purification of ceramides, which is applied in the field of functional oil preparation, can solve the problems that are not suitable for large-scale industrial extraction and production of sphingolipids, and the low utilization rate of raw materials and low yield, so as to improve the utilization rate of raw materials, The effect of low production cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

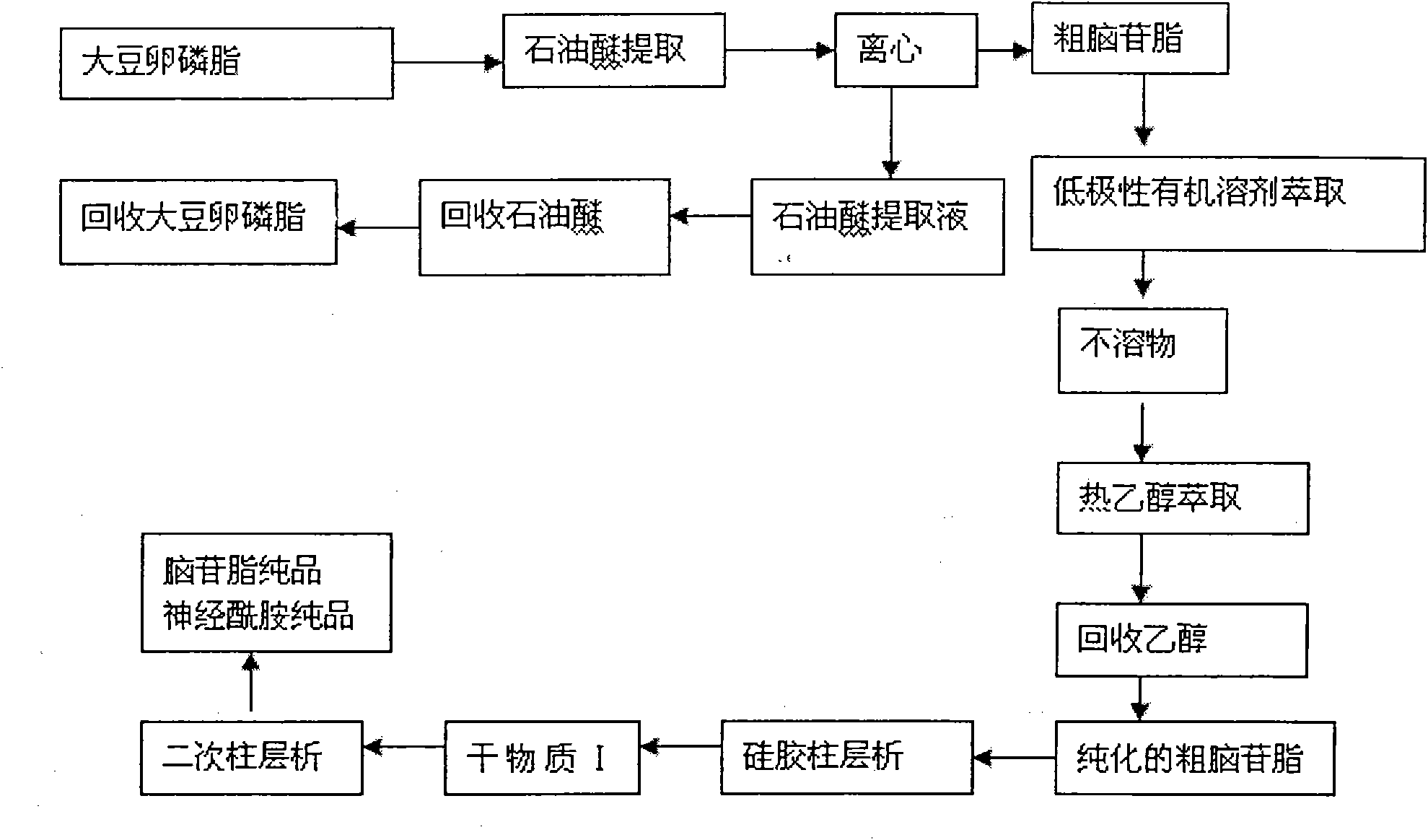

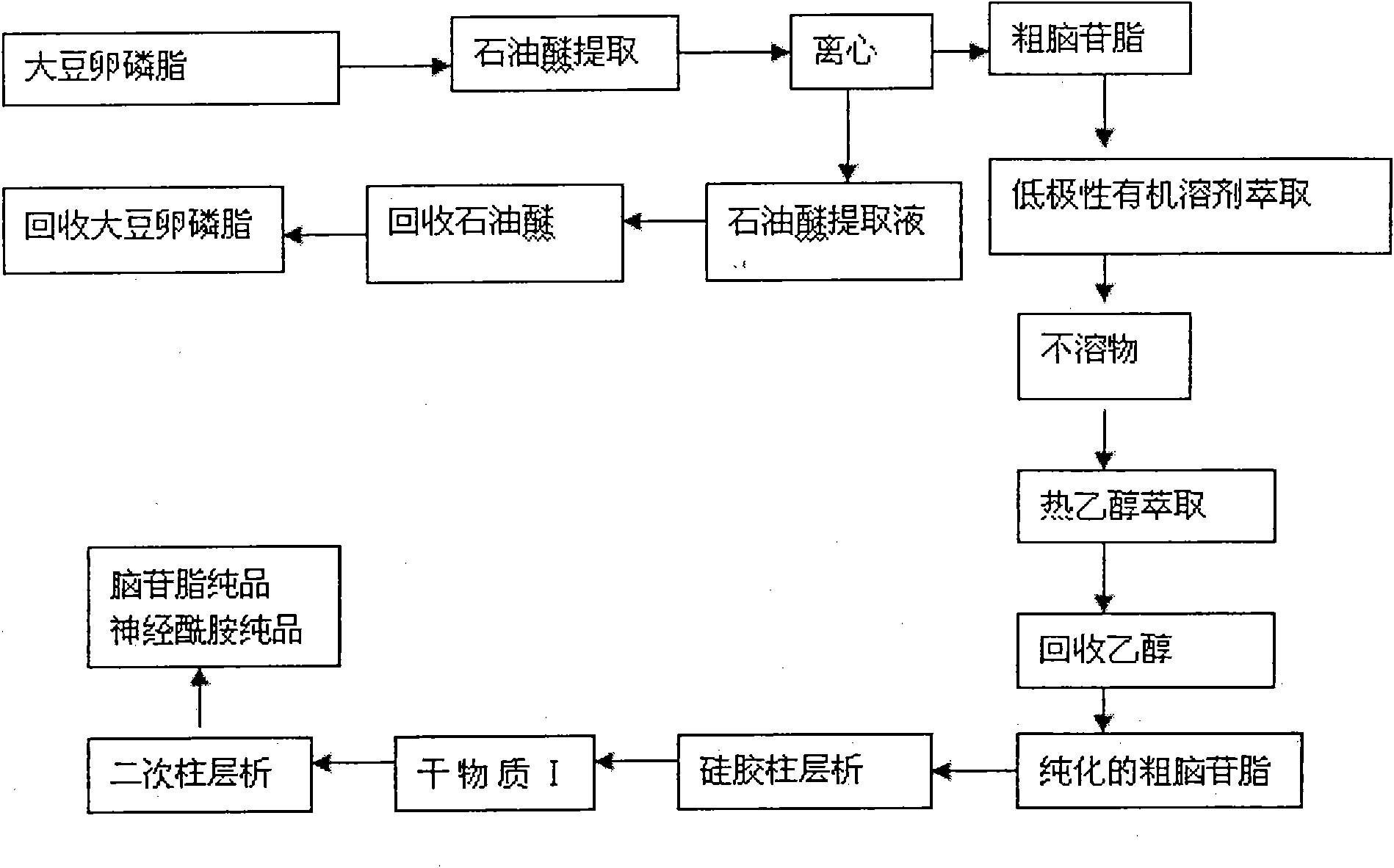

[0023] Embodiment 1: (processing route is as figure 1 shown)

[0024] (a) Extraction of crude cerebrosides: Weigh 30.0g of soybean lecithin into a 250mL conical flask, add 30ml of petroleum ether, connect a straight condenser, stir and extract under magnetic stirring for 30min, and the extraction temperature is 50°C After the extraction, cool down; transfer the extract to a centrifuge tube and centrifuge to obtain the lower layer of thick cerebroside solids; the upper layer of petroleum ether solution is concentrated and evaporated to dryness to obtain soybean lecithin after extracting cerebrosides, which can be recycled .

[0025] (b) pretreatment of crude cerebroside: the crude cerebroside solid in the lower layer is extracted once with petroleum ether (the mass volume ratio of crude cerebroside solid and petroleum ether is 1: 1), removes redundant neutral lipid, obtains Brown powdery insoluble matter; the insoluble matter was extracted 3 times with hot ethanol at a temper...

Embodiment 2

[0033] (a) Extraction of crude cerebrosides: Weigh 30.0g of soybean lecithin into a 250mL conical flask, add 60ml of petroleum ether, connect a straight condenser, stir and extract for 60min under magnetic stirring, and the extraction temperature is 30°C After the extraction, cool down; transfer the extract to a centrifuge tube and centrifuge to obtain the lower layer of thick cerebroside solids; the upper layer of petroleum ether solution is concentrated and evaporated to dryness to obtain soybean lecithin after extracting cerebrosides, which can be recycled .

[0034] (b) Pretreatment of crude cerebroside: the crude cerebroside solid in the lower layer is extracted once with normal hexane (the mass volume ratio of crude cerebroside solid and normal hexane is 1: 2), removes unnecessary neutral lipid, obtains Brown powdery insoluble matter; the insoluble matter was extracted 3 times with hot ethanol (the mass volume ratio of insoluble matter and hot ethanol was 1:3) at a tempe...

Embodiment 3

[0042] (a) Extraction of crude cerebrosides: Weigh 30.0g of soybean lecithin into a 250mL conical flask, add 90ml of petroleum ether, connect a straight condenser, stir and extract under magnetic stirring for 45min, and the extraction temperature is 40°C After the extraction, cool down; transfer the extract to a centrifuge tube and centrifuge to obtain the lower layer of thick cerebroside solids; the upper layer of petroleum ether solution is concentrated and evaporated to dryness to obtain soybean lecithin after extracting cerebrosides, which can be recycled .

[0043] (b) Pretreatment of crude cerebroside: the crude cerebroside solid in the lower layer is extracted once with industrial hexane (mass volume ratio of crude cerebroside solid and industrial hexane is 1: 3) to remove excess neutral lipid , to obtain a brown powdery insoluble matter; the insoluble matter was then extracted 3 times with hot ethanol (the mass volume ratio of the insoluble matter and hot ethanol was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com