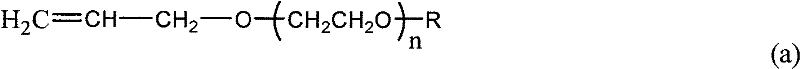

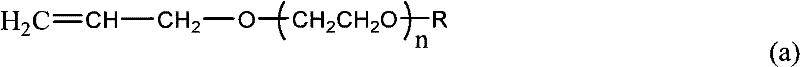

Method for preparing blocked allyl polyether

A technology of allyl polyether and hydroxyl-terminated polyether, which is applied in the field of preparation of end-capped allyl polyether, can solve the problems of low yield and low end-capping efficiency of end-capped allyl polyether, Achieve the effects of improving yield and capping efficiency, avoiding hydrolysis, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 176 grams of nonylphenol polyoxyethylene (15) ether (EO=15), 12 grams of solid potassium hydroxide and 200 milliliters of toluene in a 500 milliliter glass reactor, and replace it with nitrogen for 3 times under stirring. React with water at an azeotropic temperature of 85°C for 4 hours, and separate the water generated by the reaction through the azeotropy of toluene and water, control the amount of water output until the synthesis reaction of potassium nonylphenol polyether alcohol is completed, and lower the reaction temperature to 60°C , slowly add 20 grams of chloropropene dropwise, after the dropwise addition, heat up to 120°C and stir for 4 hours to react. After the etherification reaction is completed, carry out vacuum distillation to recover toluene, filter and desalt to separate the generated salt, and finally refine to obtain nonyl phenol-terminated allyl polyether.

Embodiment 2

[0023] Add 132 grams of nonylphenol polyoxyethylene (10) ether (EO=10), 12 grams of solid potassium hydroxide and 200 milliliters of toluene in a 500 milliliter glass reactor, and replace it with nitrogen for 3 times under stirring. React with water at an azeotropic temperature of 85°C for 4 hours, and separate the water generated by the reaction through the azeotropy of toluene and water, control the amount of water output until the synthesis reaction of potassium nonylphenol polyether alcohol is completed, and lower the reaction temperature to 60°C , slowly add 20 grams of chloropropene dropwise, after the dropwise addition, heat up to 120°C and stir for 4 hours to react. After the etherification reaction is completed, carry out vacuum distillation to recover toluene, filter and desalt to separate the generated salt, and finally refine to obtain nonyl phenol-terminated allyl polyether.

Embodiment 3

[0025] Add 176 grams of nonylphenol polyoxyethylene (15) ether (EO=15) 12 grams of solid potassium hydroxide and 200 milliliters of toluene in a glass reactor of 500 milliliters, replace with nitrogen gas 3 times under stirring, in two Toluene and water were reacted at an azeotropic temperature of 95°C for 4 hours, and the water generated by the reaction was separated by the azeotropy of xylene and water, and the amount of water was controlled until the synthesis reaction of potassium nonylphenol polyether alkoxide was completed, and the reaction temperature was lowered to Slowly add 20 grams of chloropropene dropwise at 60°C. After the dropwise addition, raise the temperature to 130°C and stir for 4 hours. After the etherification reaction is complete, carry out vacuum distillation to recover toluene, filter and desalt to separate the generated salt, and finally refine A nonylphenol-terminated allyl polyether is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com