Method for recycling methylamine hydrochloride

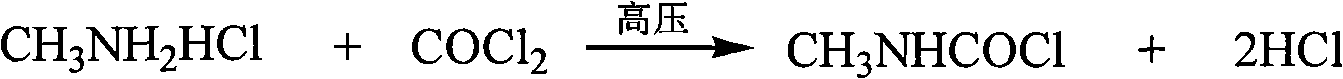

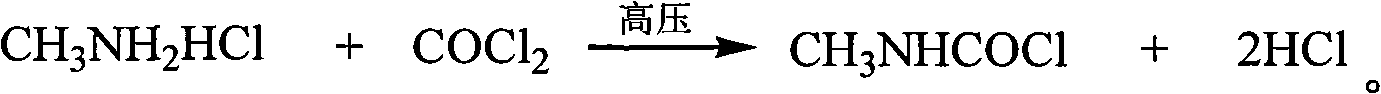

A technology of methylamine hydrochloride and methylcarbamoyl chloride, applied in the field of recycling of methylamine hydrochloride, can solve the problems of long reaction process, large consumption of phosgene, high reaction temperature, etc., to reduce energy consumption and Discharge of three wastes, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 67.5g (1.0mol) of methylamine hydrochloride, 500g (4.11mol) of chloroform, and 130g (1.31mol) of liquid phosgene into a 1000mL autoclave, stir and raise the temperature to 110°C, the pressure of the autoclave is 2.3MPa, and continue the reaction for 4h , down to room temperature after the reaction. The reaction liquid is filtered, and the weight percentage of methylcarbamoyl chloride in the filtrate is 12.5%. After the phosgene is removed by the dephosphorization tower, it enters the circulation system of the MIC production device. The filter residue is returned to the autoclave to enter the reaction process of the next batch of methylamine hydrochloride. The conversion rate of methylamine hydrochloride was 73%, and the yield was 91.8% (calculated as methylamine hydrochloride).

Embodiment 2

[0014] Add 67.5g (1.0mol) of methylamine hydrochloride, 500g (4.12mol) of chloroform, and 100g (1.01mol) of liquid phosgene into a 1000mL autoclave, stir and raise the temperature to 110°C, the pressure of the autoclave is 2.0MPa, and continue the reaction for 4h , down to room temperature after the reaction. The reaction liquid is filtered, and the weight percent of carbamoyl chloride in the filtrate is 12.2%, and the phosgene is removed by the degassing tower, and then enters the circulation system of the MIC production device. The filter residue is returned to the autoclave to enter the reaction process of the next batch of methylamine hydrochloride. The conversion rate of methylamine hydrochloride was 71.2%, and the yield was 90.5% (calculated as methylamine hydrochloride).

Embodiment 3

[0016] Add 67.5g (1.0mol) of methylamine hydrochloride, 500g (5.05mol) of 1,2-dichloroethane, 120g (1.21mol) of liquid phosgene into a 1000mL autoclave, stir and heat up to 85°C, and the pressure of the autoclave is 1.7 MPa continued to react for 5h, and the reaction was completed and dropped to room temperature. The reaction liquid is filtered, and the weight percentage of methylcarbamoyl chloride in the filtrate is 10.8%. After the phosgene is removed by the degassing tower, it enters the circulation system of the MIC production device. The filter residue is returned to the autoclave to enter the reaction process of the next batch of methylamine hydrochloride. The conversion rate of methylamine hydrochloride was 62.2%, and the yield was 93.5% (calculated as methylamine hydrochloride).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com