Insulating coating on side face of zinc oxide lightning arrester valve plate and coating method thereof

A technology of insulating coating and lightning arrester, which is applied in coatings, devices for coating liquid on the surface, and surface pretreatment, etc. It can solve the problem that the insulation performance of the side cannot be achieved, the insulating coating is difficult to resist the impact of super large current, and it is unfavorable to form a complete continuous problems such as dense insulating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

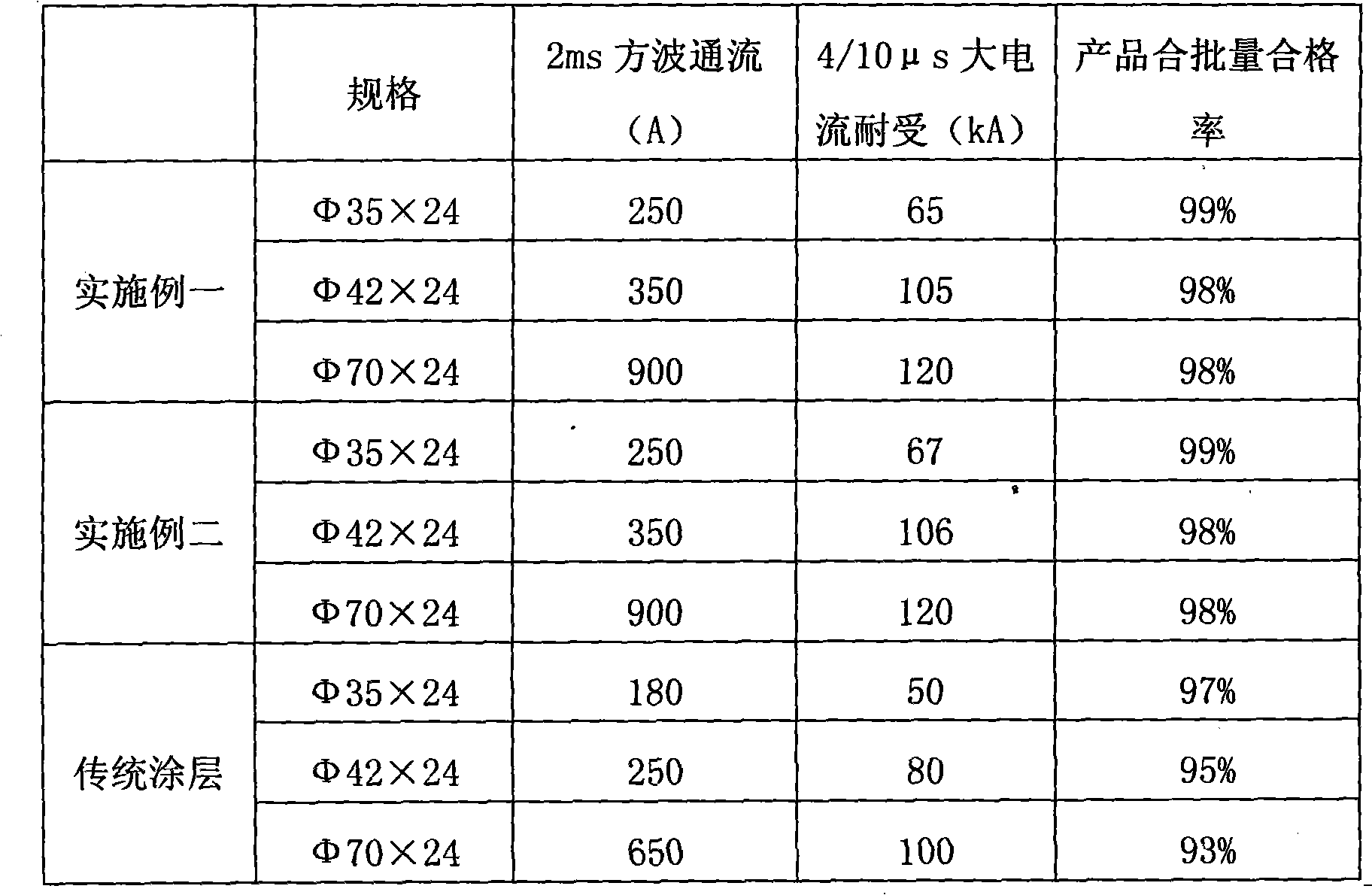

Embodiment 1

[0018] Embodiment 1: The insulating coating material on the side of the zinc oxide surge arrester valve plate is by weight percentage: fluorocarbon resin: SiO2 or Al2O3: isocyanate: myristyl ammonium acetate or PEG2000: methyltrimethoxysilane or carboxylated nitrile rubber: sec-butyl acetate=65:15:10:3:3:4.

[0019] The coating method of the insulating coating on the side of the zinc oxide surge arrester valve plate comprises the following steps:

[0020] a. All components of the insulating coating on the side of the zinc oxide surge arrester valve plate were mixed and dispersed with a sand mill for 3 hours, and filtered through a 120 mesh screen;

[0021] b. Grind the upper and lower surfaces of the zinc oxide surge arrester valve with a diamond double-end grinder; then clean it with an ultrasonic cleaner, then put it in an oven and bake it at 120°C for 2 to 3 hours, spray aluminum on the upper and lower surfaces of the valve Then vertically stacked, the thickness of sprayed...

Embodiment 2

[0023] Embodiment two: the insulating coating material on the side of the zinc oxide surge arrester valve plate is by weight percentage: fluorocarbon resin: SiO2: isocyanate: myristyl ammonium acetate: methyltrimethoxysilane: sec-butyl acetate=70:10: 10:3:3:4.

[0024] The coating method of the insulating coating on the side of the zinc oxide surge arrester valve plate comprises the following steps:

[0025] a. All components of the insulating coating on the side of the zinc oxide surge arrester valve plate were mixed and dispersed with a sand mill for 3 hours, and filtered through a 120 mesh stainless steel screen to obtain a good fluidity, uniform and stable coating;

[0026] b. Grind the upper and lower surfaces of the zinc oxide surge arrester valve with a diamond double-end grinder; then clean it with an ultrasonic cleaner, and then put it in an oven and bake it at 120°C for 2 to 3 hours. After the upper and lower surfaces of the valve are sprayed with aluminum Stacked v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com