Preparation method of blue light luminescent material composited by stannic oxide and manganese oxide

A tin dioxide and blue light emitting technology, applied in the directions of luminescent materials, chemical instruments and methods, etc., can solve the problems of no tin oxide composite blue light emitting material, inability to achieve obvious improvement, low luminous efficiency, etc., and achieve a wide range of applications, Excellent stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

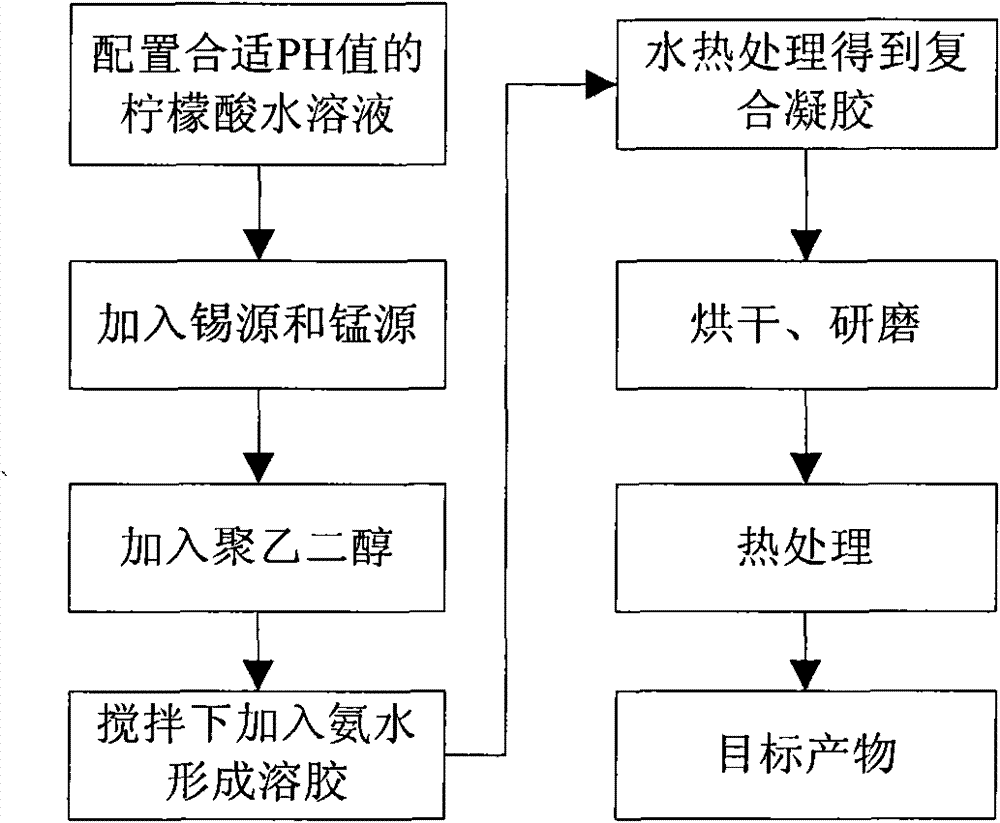

Method used

Image

Examples

Embodiment approach 1

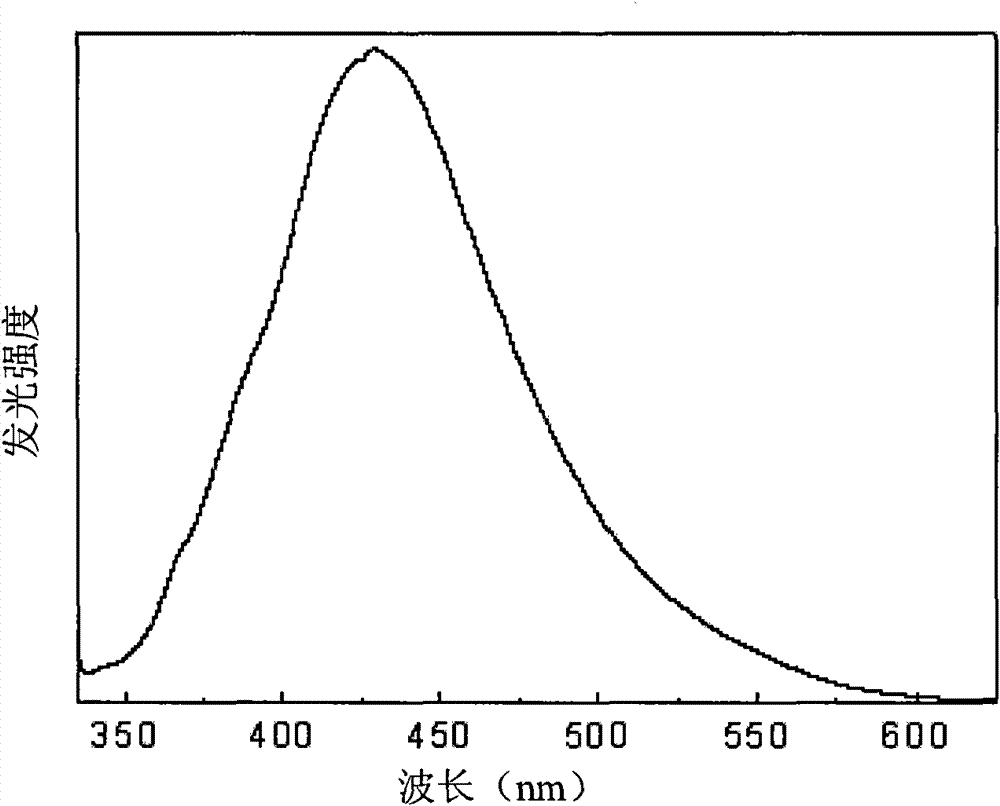

[0027] Under stirring, add citric acid to 1000ml of deionized water at a constant temperature of 50°C until the pH of the solution is 1.5, then add 87.5 grams of tin tetrachloride pentahydrate and 49.5 grams of manganous chloride hexahydrate, stir to dissolve, and obtain a clear solution A . Then add 100ml polyethylene glycol solution, after stirring for 10 minutes, under stirring, add 300ml of ammonia water within 20 minutes to form tan sol B. Then add B into a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction at 150°C for 12 hours to obtain a tin dioxide / manganese oxide composite gel. The resulting gel was dried at 110°C and ground. Then heat treatment at 200° C. in the air for 1 hour to obtain a tin dioxide / manganese oxide composite luminescent material with a molar ratio of tin and manganese of 1:1. The photoluminescence spectrum shows that this tin dioxide / manganese oxide composite luminescent material emits strong blue light under the excitati...

Embodiment approach 2

[0029] The preparation process of the above-mentioned Example 1 was adopted, except that 140.2 grams of tin tetrachloride pentahydrate and 19.8 grams of manganous chloride hexahydrate were added. The prepared tin dioxide / manganese oxide composite luminescent material has a molar ratio of tin and manganese of 75:25.

Embodiment approach 3

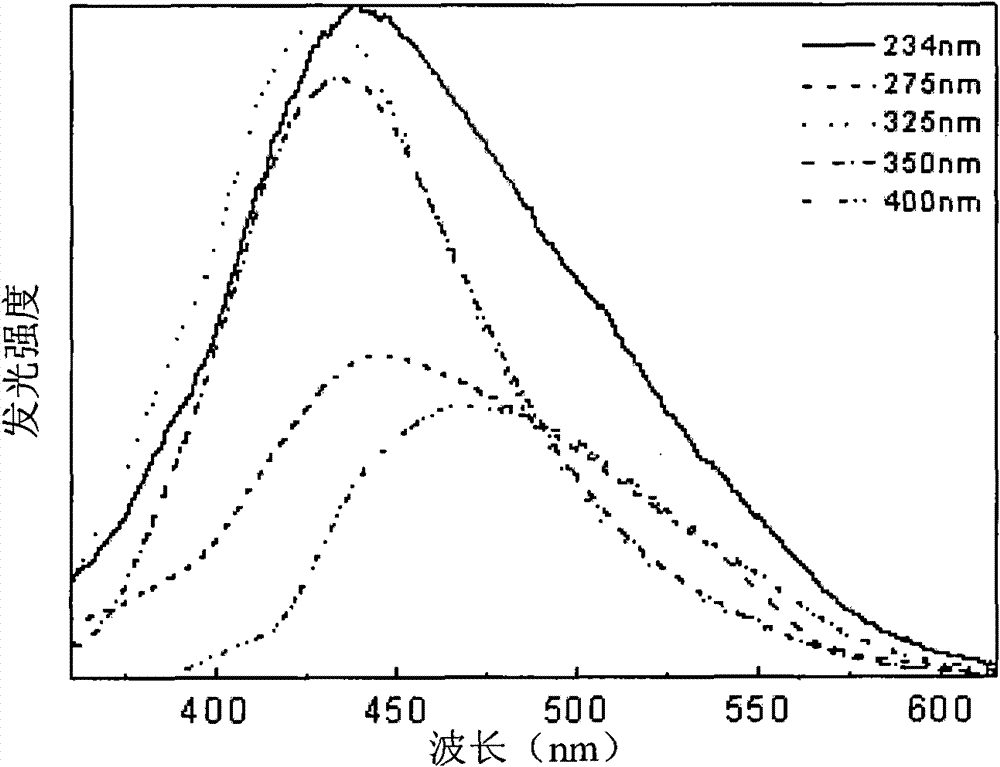

[0031] The preparation process of the above-mentioned Example 1 was adopted, except that 35.02 grams of tin tetrachloride pentahydrate and 79.2 grams of manganous chloride hexahydrate were added. The prepared tin dioxide / manganese oxide composite luminescent material has a molar ratio of tin and manganese of 25:75. The photoluminescence spectrum shows that this tin dioxide / manganese oxide composite luminescent material also emits strong blue light under the excitation of ultraviolet rays, ranging from 350-600nm, and the luminescence is the strongest under the excitation of 343nm ultraviolet rays, and the luminescence peak is 434nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com