Cleaning agent for windshield glass

A windshield and cleaning agent technology, which is applied in the direction of detergent compounding agent, detergent composition, organic cleaning composition, etc., can solve the problems of affecting the driver's vision and the complex composition of dirt, so as to maintain the transparency of the glass and clean it well Stain removal performance, detergency without cloud point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

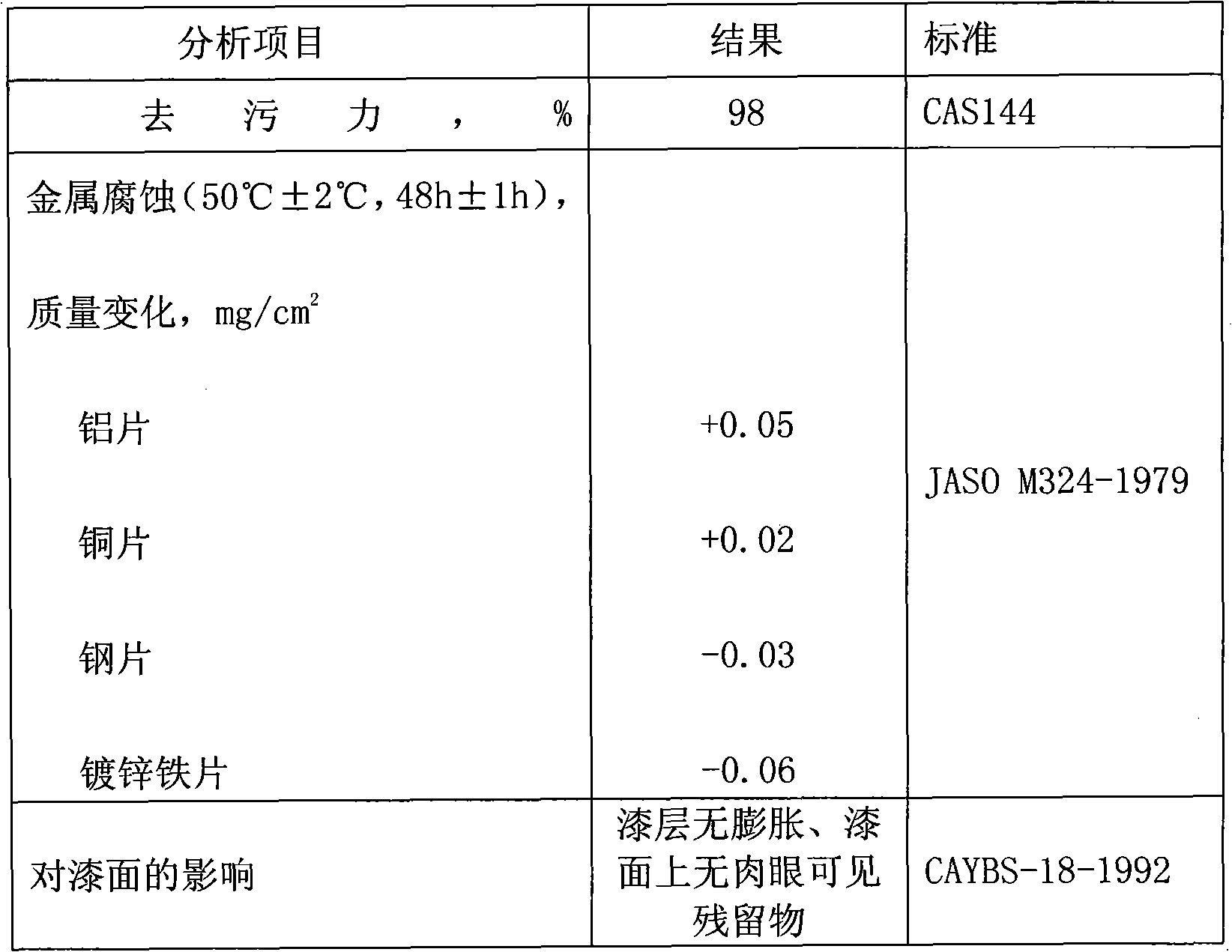

Examples

Embodiment 1

[0021] Take 0.1kg of alkyl glucoside (C8-C10), 0.6kg of sodium lauryl polyoxyethylene ether phthalate monoester, 1.0kg of propylene glycol monomethyl ether, 0.3kg of polyvinylpyrrolidone K-15, 2-phosphonobutyl 0.01kg of alkane-1,2,4-tricarboxylic acid, 1.0kg of 1,3-propanediol, 60.0kg of ethanol and 40.0kg of deionized water are mixed and stirred to form a product.

Embodiment 2

[0023] Take 0.2kg of alkyl glucoside (C8-C10), 0.3kg of sodium lauryl polyoxyethylene ether phthalate monoester, 2.0kg of propylene glycol monomethyl ether, 0.2kg of polyvinylpyrrolidone K-15, 2-phosphono 0.03kg of butane-1,2,4-tricarboxylic acid, 2.0kg of 1,3-propanediol, 40.0kg of ethanol and 50.0kg of deionized water are mixed and stirred to form the product.

Embodiment 3

[0025] Take 0.5kg of alkyl glucoside (C8-C10), 0.1kg of sodium lauryl polyoxyethylene ether phthalate monoester, 3.0kg of propylene glycol monomethyl ether, 0.1kg of polyvinylpyrrolidone K-15, 2-phosphonobutyl 0.05kg of alkane-1,2,4-tricarboxylic acid, 3.0kg of 1,3-propanediol, 30.0kg of ethanol and 70.0kg of deionized water are mixed and stirred to form a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com