Near ultraviolet excited white light fluorescent powder and preparation method thereof

A fluorescent powder and near-ultraviolet technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of white light attenuation, achieve the effects of narrow particle size distribution, uniform particles, and lower reaction sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] According to the chemical formula CaGdAl 3 o 7 :0.03Ce 3+ , 0.19Tb 3+ The mole fraction ratio of the composition weighs CaCO 3 , Gd 2 o 3 , Al 2 o 3 , CeO 2 , Tb 4 o 7 , and weigh 5% of the total weight of the above raw materials H 3 BO 3 As a co-solvent, put all the above-mentioned raw materials in a planetary ball mill for 4 hours, mix well, dry, and pass through a 200-mesh sieve. Put the obtained powder into an alumina crucible, place the crucible in a graphite box, put it into a muffle furnace, and sinter in a reducing atmosphere formed by active graphite powder. The powder is kept at 800°C for 4 hours, and at 1300°C for 6 hours. Hours, cool with the furnace, grind and refine, and pass through a 300-mesh sieve; put it in 50°C water for 15 minutes, let it stand, filter its supernatant, then add it into 50°C water for 15 minutes, let it stand, filter its supernatant , repeat 3 times, take out the precipitate, dry it, and get phosphor powder.

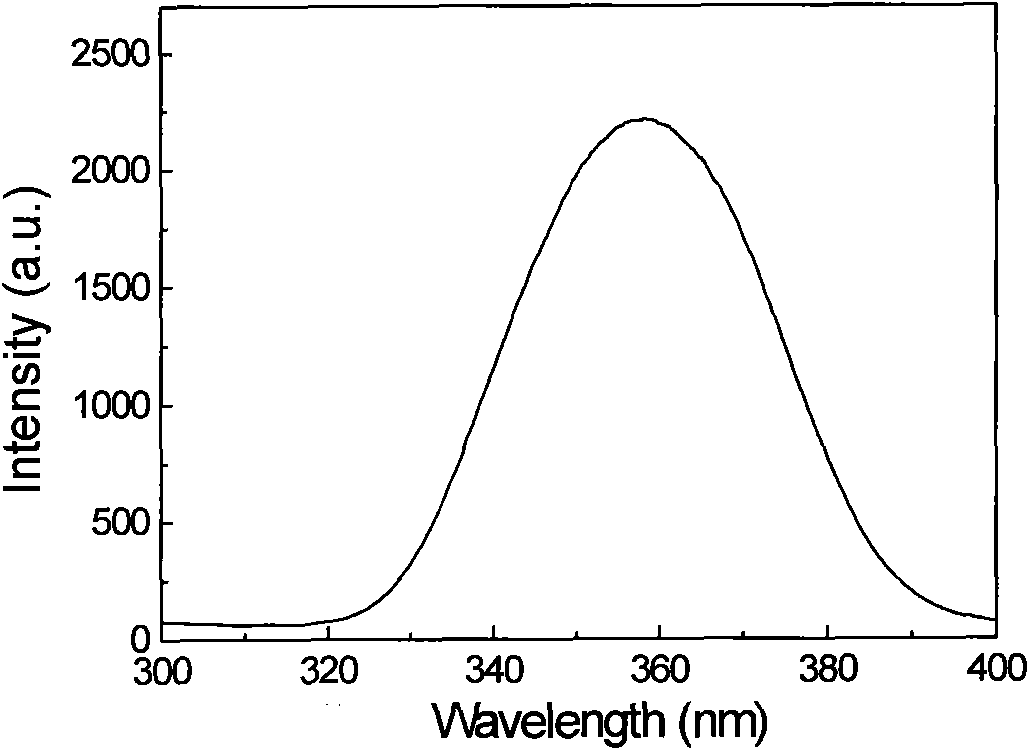

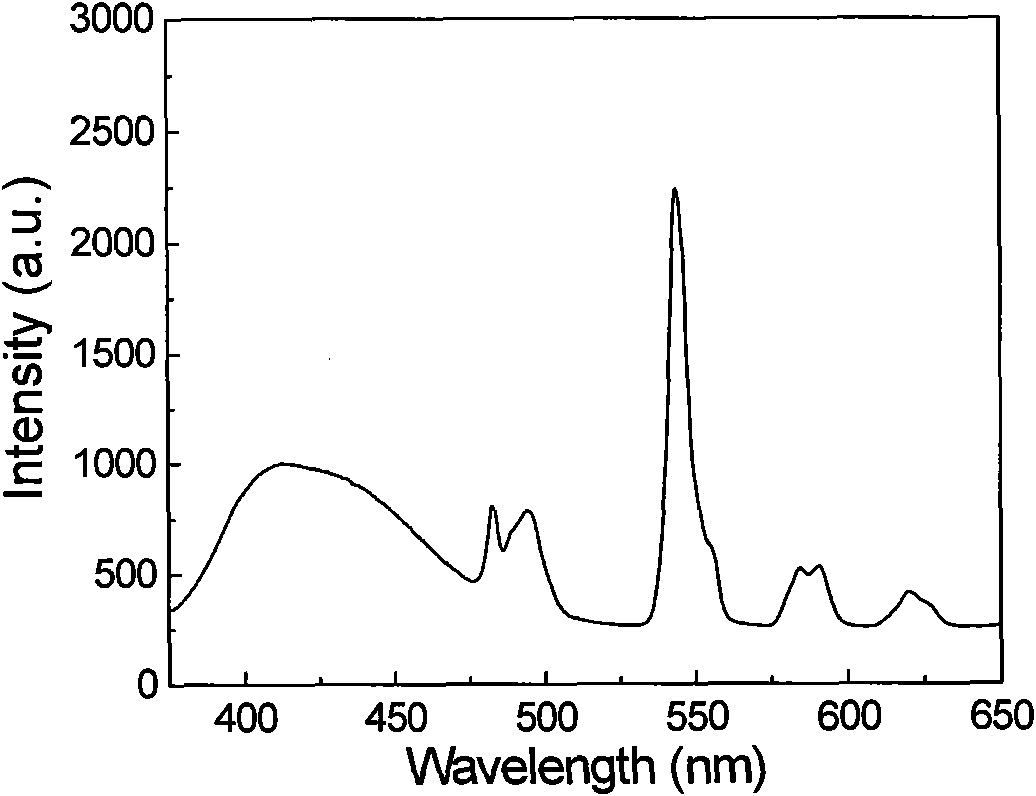

[0014] The...

Embodiment 2

[0017] According to the chemical formula CaY 0.25 Gd 0.75 al 3 o 7 :0.05Ce 3+ , 0.20Tb 3+ The mole fraction ratio of the composition weighs CaCO 3 , Y 2 o 3 , Gd 2 o 3 , Al 2 o 3 , CeO 2 , Tb 4 o 7 , and weighed the total weight of the above raw materials 7% H 3 BO 3 As a co-solvent, put all the above-mentioned raw materials in a planetary ball mill for 4 hours, mix well, dry, and pass through a 200-mesh sieve. Put the obtained powder into an alumina crucible, place the crucible in a graphite box, put it into a muffle furnace, and sinter in a reducing atmosphere formed by active graphite powder. The powder is kept at 900°C for 6 hours, and at 1350°C for 7 hours. Hours, cool with the furnace, grind and refine, and pass through a 300-mesh sieve; put it in 70°C water for 20 minutes, let it stand, filter the supernatant, then add 70°C water for 20 minutes, stand still, filter the supernatant , repeat 3 times, take out the precipitate, dry it, and get phosphor powd...

Embodiment 3

[0020] According to the chemical formula CaY 0.5 Gd 0.5 al 3 o 7 :0.07Ce 3+ , 0.24Tb 3+ The mole fraction ratio of the composition weighs CaCO 3 , Y 2 o 3 , Gd 2 o 3 , Al 2 o 3 , CeO 2 , Tb 4 o 7 , and weigh 5% of the total weight of the above raw materials K 2 CO 3 As a co-solvent, put all the above-mentioned raw materials in a planetary ball mill for 4 hours, mix well, dry, and pass through a 200-mesh sieve. Put the obtained powder into an alumina crucible, place the crucible in a graphite box, put it into a muffle furnace, and put it in a N 2 and H 2 Sintering in a reducing atmosphere formed by a mixed gas with a molar ratio of 95:5, the powder is kept at 800°C for 6 hours, at 1250°C for 8 hours, cooled with the furnace, ground and refined, and passed through a 300-mesh sieve; put into 80°C Sonicate in water for 15 minutes, let it stand still, filter the supernatant, then add water at 80°C and sonicate for 15 minutes, let it stand, filter the supernatant, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com