Aspergillusniger strain and application thereof

A technology of Aspergillus niger strain and Aspergillus niger, which is applied in the field of enzyme engineering, can solve problems such as low fermentation enzyme activity, and achieve the effects of stable yield, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

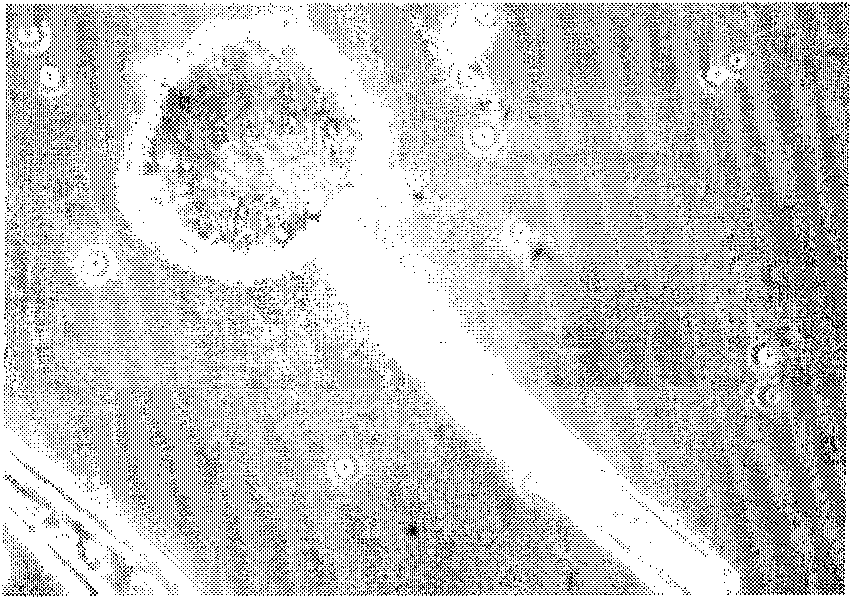

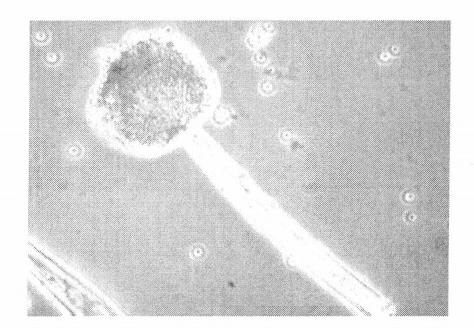

Image

Examples

example 1

[0031] Slope seed medium: add 20g of glucose and 20g of agar to the infusion juice made from 200g of potatoes, add tap water to make the volume to 1000ml, and the pH is natural. This slant is used for strain activation, preservation and test tube slant seeds, etc.

[0032] Screening double layer Congo red medium:

[0033] K H 2 PO 4 1g, (NH 4 ) 2 SO 4 0.7g, MgSO 4 0.3g, CaCl 2 0.15g, 0.5ml Mandel’s Nutrient Solution——constant volume to 500ml…recorded as solution (1)

[0034] The lower layer is 200ml solution (1)+4g agar

[0035]The upper layer is 1g of CMC, 0.1g of sodium deoxycholate, and 0.01g of Congo red, which are dissolved in 100ml of solution (1), and 1g of agar is added.

[0036] The initial bacteria were derived from the activated sludge of the wastewater treatment plant. Dilute the activated sludge, suspend it in sterile water, add fermentation medium, and incubate at 30°C for 72-84h. Take an appropriate amount of culture solution, press 10 -4 , 10 -...

example 2

[0038] Nitrite mutagenesis: 0.2 mol / L acetic acid and 0.2 mol / L sodium acetate were formulated into acetic acid-sodium acetate buffer solution with pH 4.4 at 63:37 (V / V), and the slant was mixed with acetic acid-sodium acetate buffer solution Aspergillus niger T2 spores on the surface were washed to make acetic acid spore suspension. Add 0.1mol / L NaNO 2 Solution 2mL, after mutagenesis for 5min and 10min, add 2mL 0.7mol / L Na 2 HPO 4 solution as a terminator. Take 0.05mol / L NaNO with the same operation 2 Perform mutagenesis. The bacterial solution after the above treatment and the blank control were serially diluted, and diluted to the original concentration of 10 -3 、10 -4 、10 -5 0.2mL each of the solution was coated on a plate, numbered and placed in a 30°C incubator. After 72 hours of constant temperature cultivation, a single colony with a large transparent circle was picked out, and a liquid fermentation experiment was carried out in a conical flask to determine the ...

example 3

[0042] Preparation of fermentation medium: 4.95g corncobs, 3.5g yeast powder, KH in a 500ml Erlenmeyer flask 2 PO 4 0.4g, MgSO 4 0.06g, CaCl 2 0.06g, trace elements: FeSO 4 1mg, MnSO 4 0.32mg, ZnSO 4 0.2mg, add water to 200ml, pH 5.0.

[0043] Seed preparation: put the above-mentioned culture medium in the Erlenmeyer flask (500ml), sterilize at 121° C. for 30 minutes, inoculate Aspergillus niger T2 of the present invention at 10% after cooling, and cultivate at a constant temperature of 28-33° C. for 24 hours.

[0044] Liquid state fermentation: sterilize the above medium at 121°C for 30 minutes, inoculate the prepared seeds into the medium at 10% after cooling, cultivate for 72 hours at 30°C with a rotation speed of 200 rpm. The test results of the above-mentioned Erlenmeyer flasks repeated for 4 batches showed that the average enzyme activity of β-glucosidase reached 2.46U / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com