Device and method for protein feed production by recycling of aquaculture wastewater treatment process

An aquaculture, feed protein technology, applied in feed, animal feed, animal feed and other directions, can solve the problems of low carbon source release efficiency, low efficiency of nutrient salt assimilation and utilization, contrary to environmental friendliness, etc., to improve the assimilation and utilization of nutrient salt. Efficiency, high processing load per unit volume, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

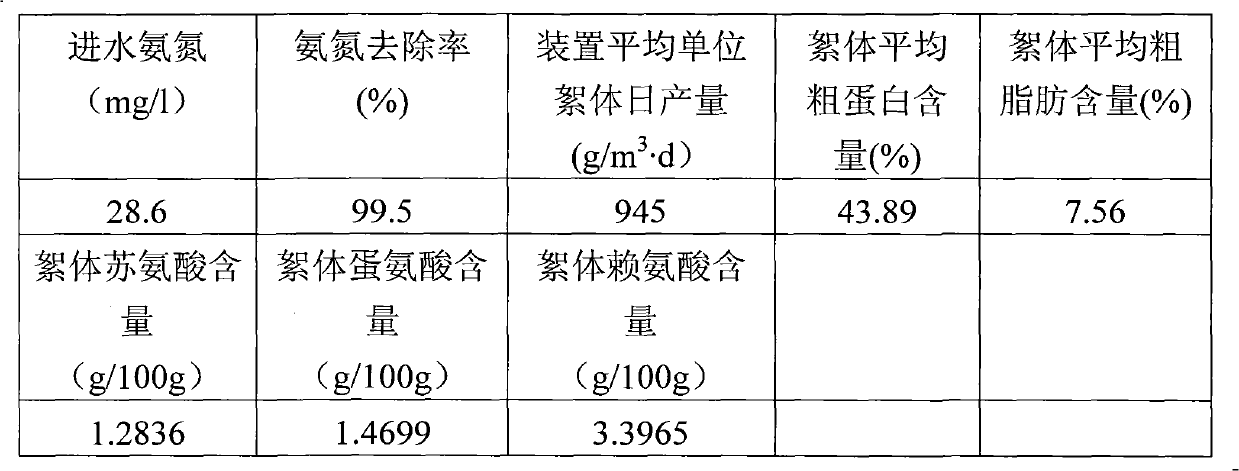

Examples

Embodiment Construction

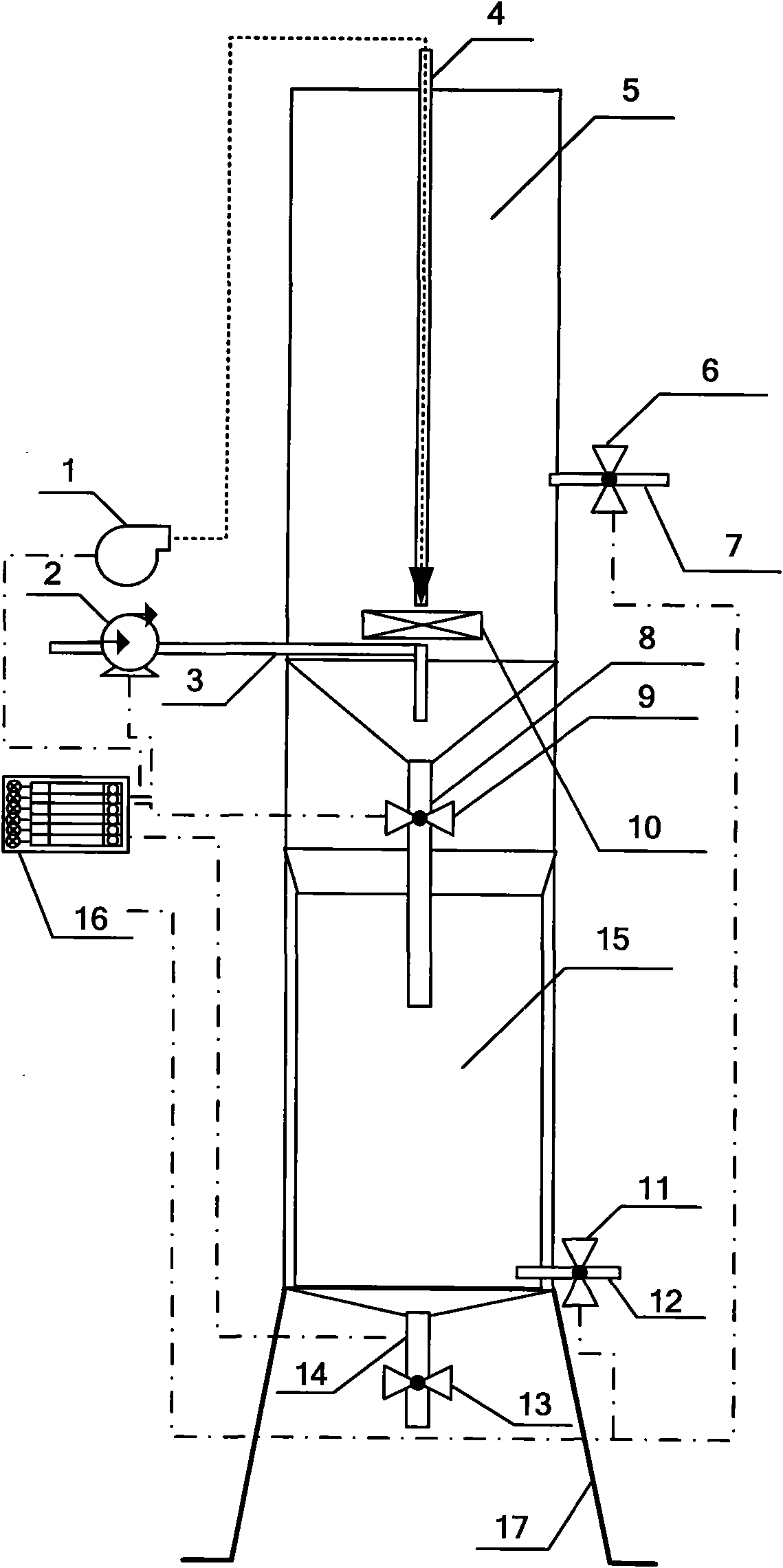

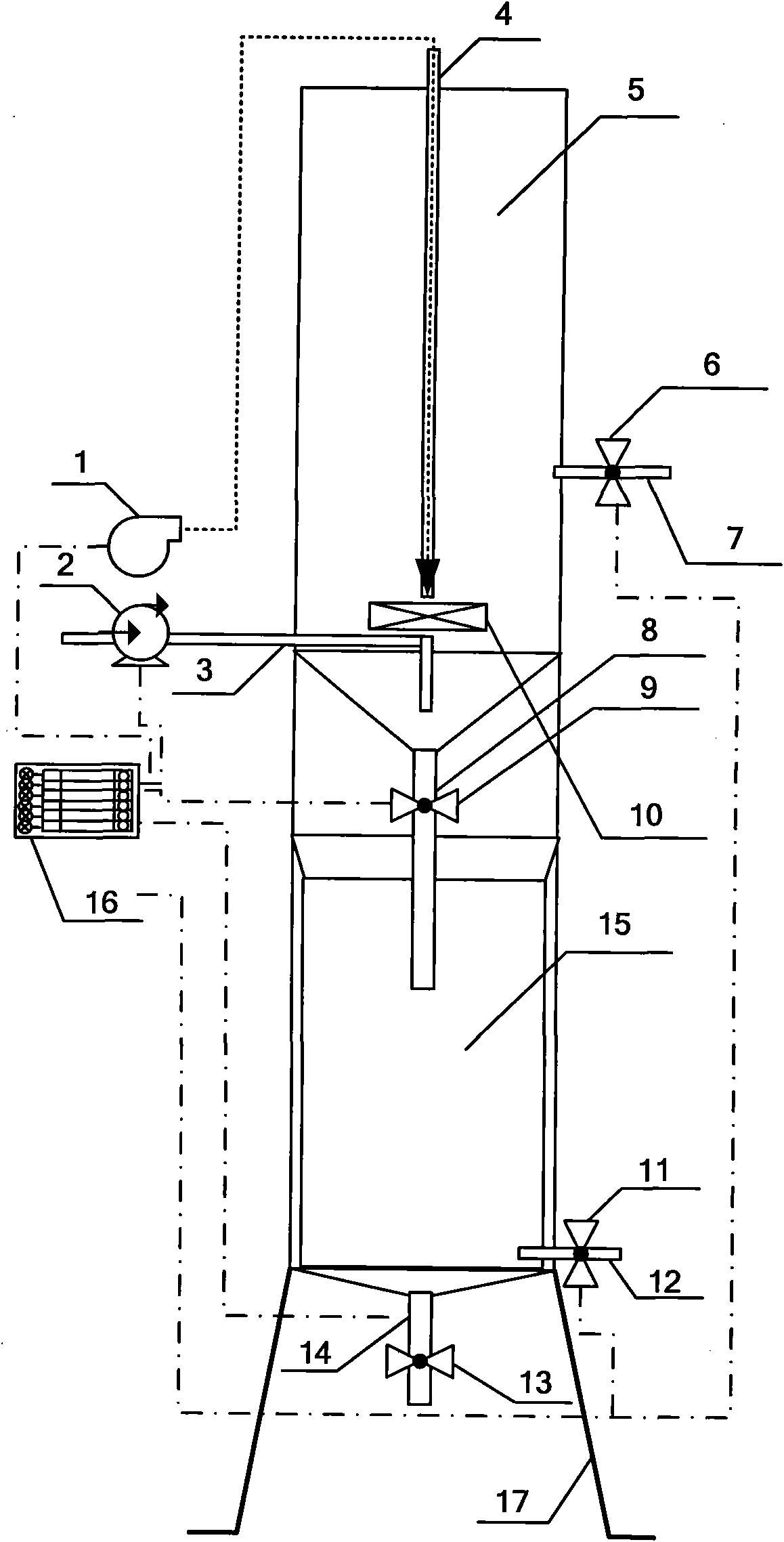

[0019] The device of the present invention for the production of feed protein by resource utilization in the biological treatment process of aquaculture wastewater comprises: a blower 1, a metering pump 2, a water inlet pipe 3, an air guide pipe 4, a reaction chamber 5, a first electromagnetic valve 6, an upper drain pipe 7, and an upper mud discharge Pipe 8, second solenoid valve 9, disc air distributor 10, third solenoid valve 11, lower drain pipe 12, fourth solenoid valve 13, lower mud discharge pipe 14, resource recovery chamber 15, programmable controller 16 , device support frame 17.

[0020] The connection relationship of each part of the device is as follows: the blower 1 is connected with the air guide tube 4 by a flexible pipe, the air guide tube 4 is inserted vertically downward at the center position of the top of the reaction chamber 5, the height of the top of the air guide tube 4 is 2-5 cm from the top of the reaction chamber 5, and the guide tube 4 The distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com