Photovoltaic glass plated with temperable anti-reflection film layer and manufacturing method thereof

A technology of anti-reflection film and photovoltaic glass, which is applied in the field of photovoltaic glass and its production, can solve the problem of anti-reflection film layer hardness, acid and alkali resistance, weather resistance or adhesion is not very high, can not withstand thermal shock, anti-reflection effect Weaken and other problems, to achieve the effect of high film adhesion, good hardness, and high power generation increment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

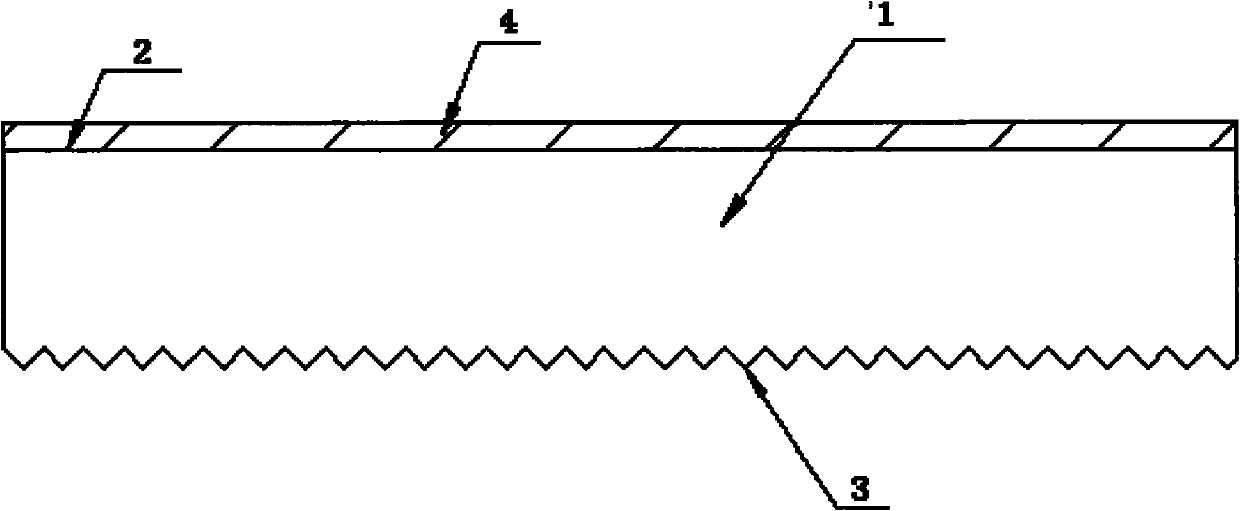

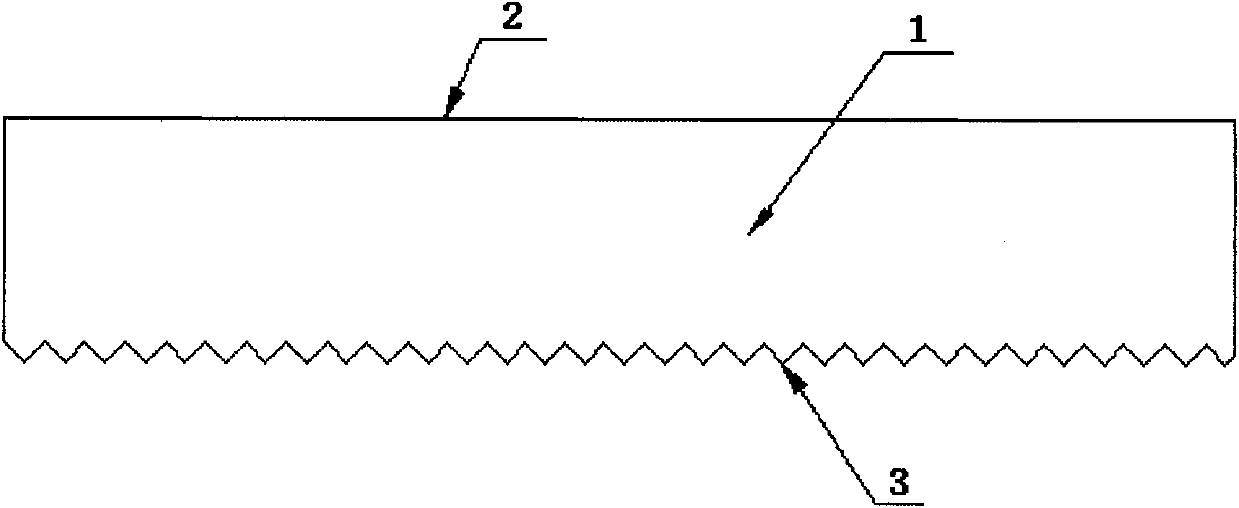

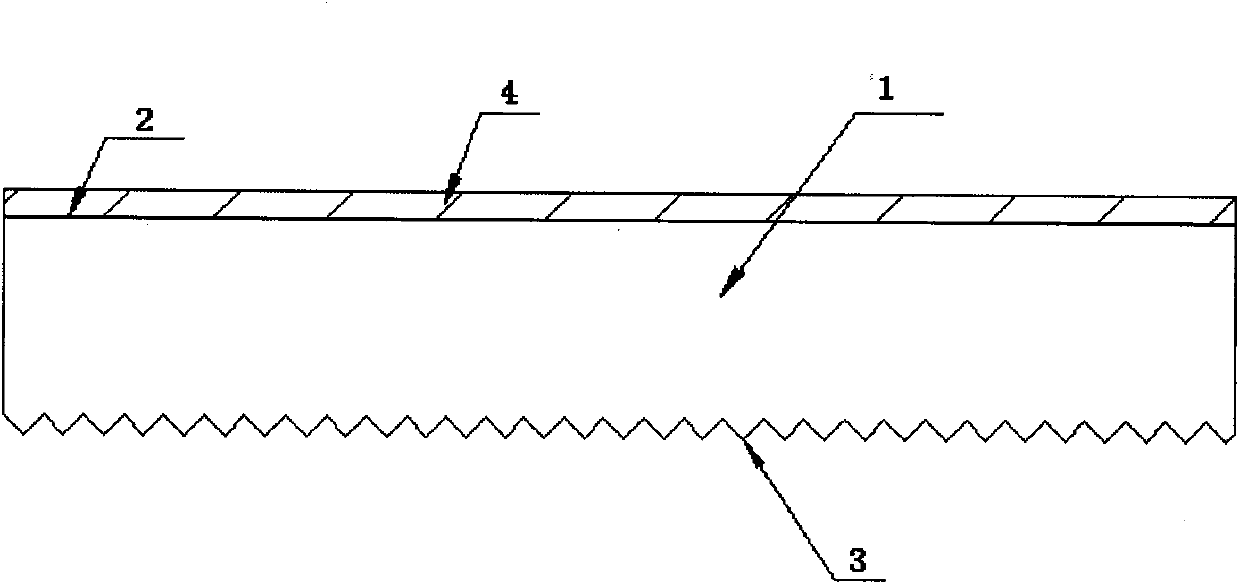

[0026] Such as figure 1 and figure 2As shown, a photovoltaic glass coated with a toughened anti-reflection coating. It includes a low-iron ultra-clear patterned glass substrate 1 and an anti-reflection film layer 4, the anti-reflection film layer 4 is coated on the suede surface 2 of the low-iron ultra-clear patterned glass substrate 1, and the anti-reflection film layer 4 The main component is silicon dioxide, and the thickness of the anti-reflection film layer 4 is 120nm. The production method of this glass is: use orthoethyl silicate (TEOS) as the precursor, ammonia water as the catalyst to make silica sol, and obtain an anti-reflection coating solution by diluting and adding stabilizers, binders, etc., wherein the raw materials And the ratio of the amount of catalyst substance: tetraethyl orthosilicate: water: ethanol: ammonia water = 1: 4: 80: 5; the amount of stabilizer added is 1 g per liter of coating solution; the amount of binder added is added per liter of coatin...

Embodiment 2

[0028] like figure 1 and figure 2 As shown, a photovoltaic glass coated with a toughened anti-reflection coating. It includes a low-iron ultra-clear patterned glass substrate 1 and an anti-reflection film layer 4, the anti-reflection film layer 4 is coated on the suede surface 2 of the low-iron ultra-clear patterned glass substrate 1, and the anti-reflection film layer 4 The main component is silicon dioxide, and the thickness of the anti-reflection film layer 4 is 150nm. The production method of this glass is: use orthoethyl silicate (TEOS) as a precursor, hydrochloric acid as a catalyst to prepare silica sol, and obtain an anti-reflection coating solution by diluting and adding stabilizers, binders, etc.; the raw materials And the amount ratio of catalyst substance: tetraethyl orthosilicate: water: ethanol: hydrochloric acid=1: 2: 30: 1; The addition amount of stabilizer is that every liter of coating solution adds 3g; The amount of binder addition is that every liter of ...

Embodiment 3

[0030] like figure 1 and figure 2 As shown, a photovoltaic glass coated with a toughened anti-reflection coating. It includes a low-iron ultra-clear patterned glass substrate 1 and an anti-reflection film layer 4, the anti-reflection film layer 4 is coated on the suede surface 2 of the low-iron ultra-clear patterned glass substrate 1, and the anti-reflection film layer 4 The main component is silicon dioxide, and the thickness of the anti-reflection film layer 4 is 180nm. The production method of this glass is: use orthoethyl silicate (TEOS) as a precursor, hydrochloric acid as a catalyst to prepare silica sol, and obtain an anti-reflection coating solution by diluting and adding stabilizers, binders, etc.; the raw materials And the amount ratio of catalyst substance: tetraethyl orthosilicate: water: ethanol: hydrochloric acid=1: 3: 50: 3; The addition amount of stabilizer is that every liter of coating solution adds 5g; The amount of binder addition is that every liter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com