All-weather and full-automatic multi-layer temperature-control circular greenhouse

A technology for greenhouses and implementation methods, which is applied in greenhouse cultivation, botany equipment and methods, and roof coverings, etc., and can solve the problems that crops in the shed cannot make full use of sunlight, the construction cost of solar greenhouses is high, and insulation materials cannot be used to keep warm, etc. problems, to achieve the effect of protecting physical and mental health, improving the ability to resist severe weather, and improving the ability to resist severe weather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

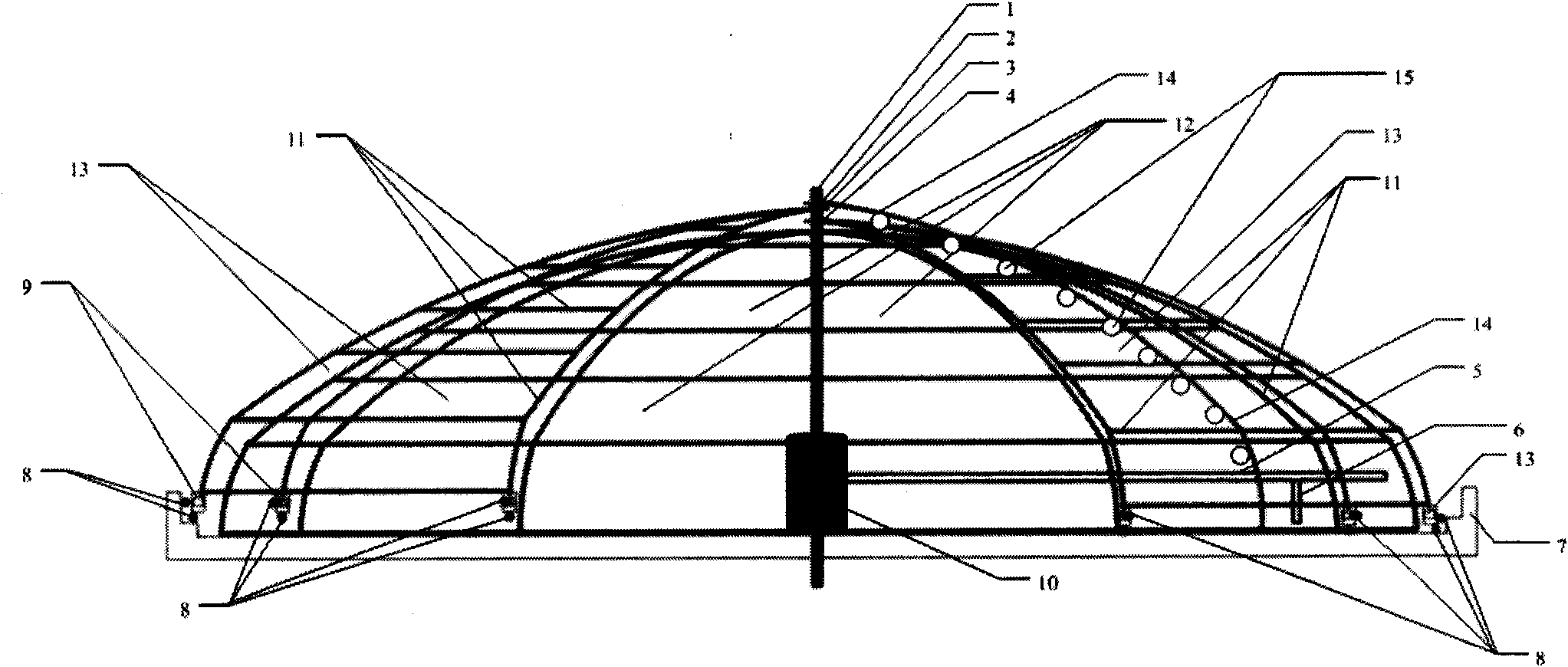

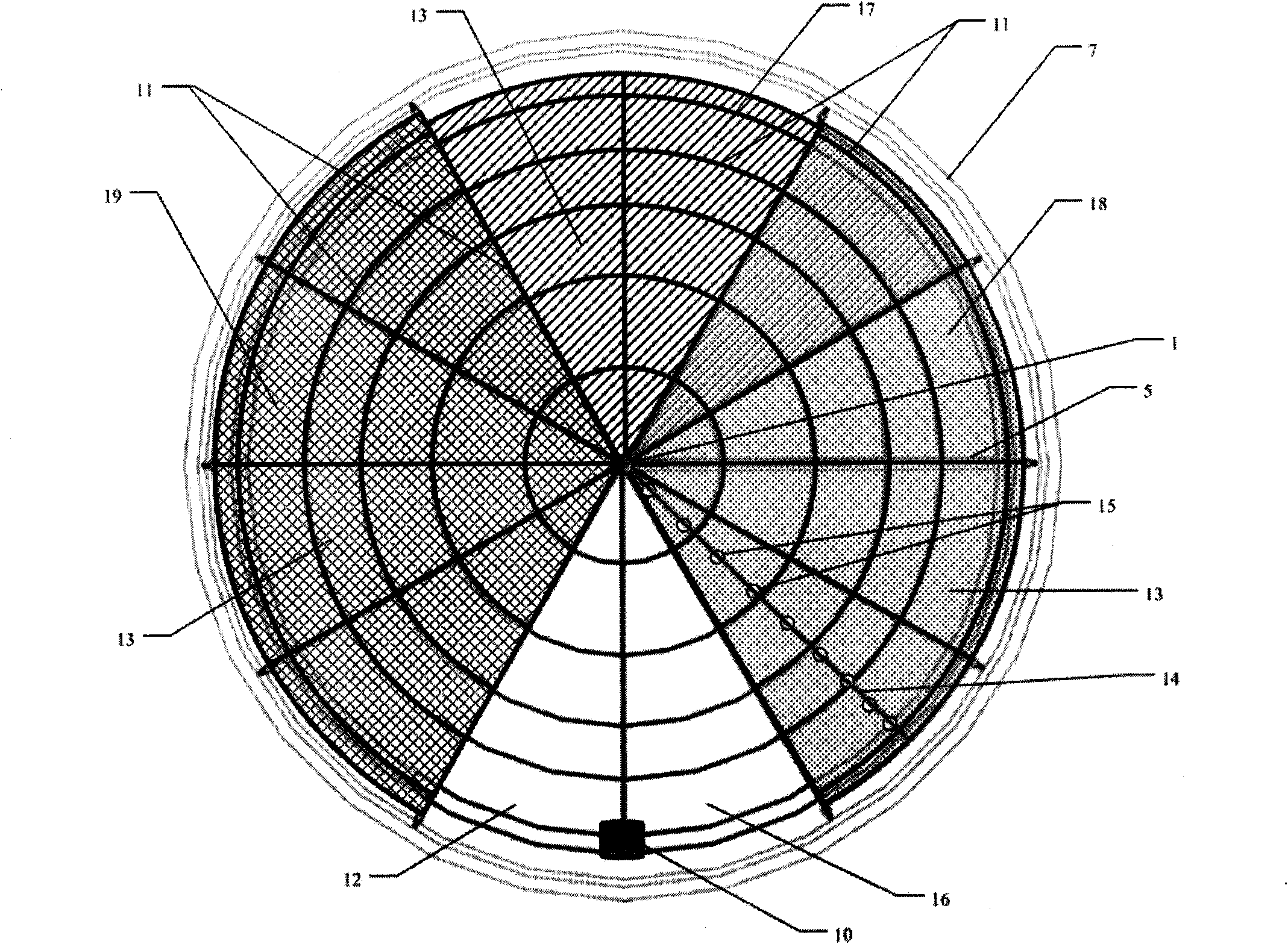

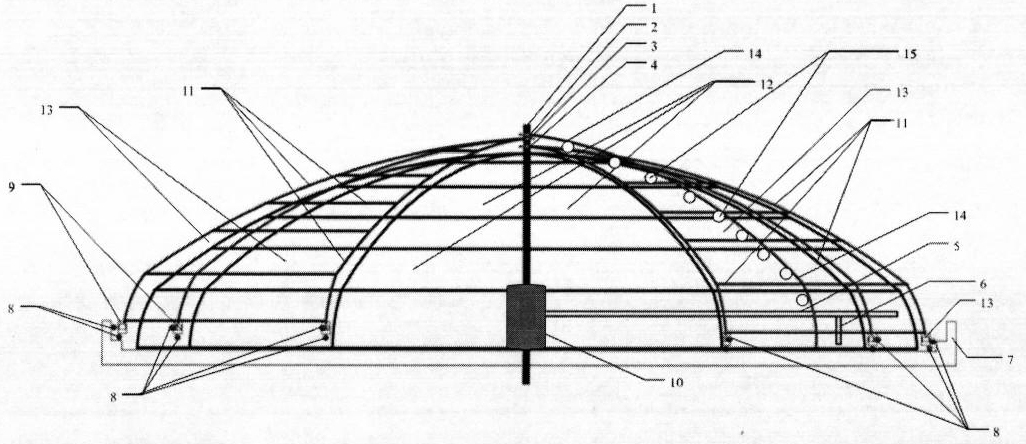

[0022] The installation structure of the present invention is as follows: the present invention is attached figure 1 , attached figure 2 The all-weather, fully automatic multi-layer temperature-controlled circular greenhouse is installed on a piece of land with a length × width of 33m × 20m. It includes support column 1, rotating device 2 of the i+1 layer, rotating device 3 of the i layer, rotating device 4 of the first layer, horizontal working arm 5, vertical working arm 6, level track 7, moving device 8, driving device 9 , door 10, skeleton 11, light-transmitting film 12, thermal insulation filling material 13, snow plowing arm 14, snow plow 15, 0th daylighting layer 16, 0th thermal insulation layer 17, ith thermal insulation layer 18, ith thermal insulation layer +1 layer of insulation layer 19, assembled cost invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com