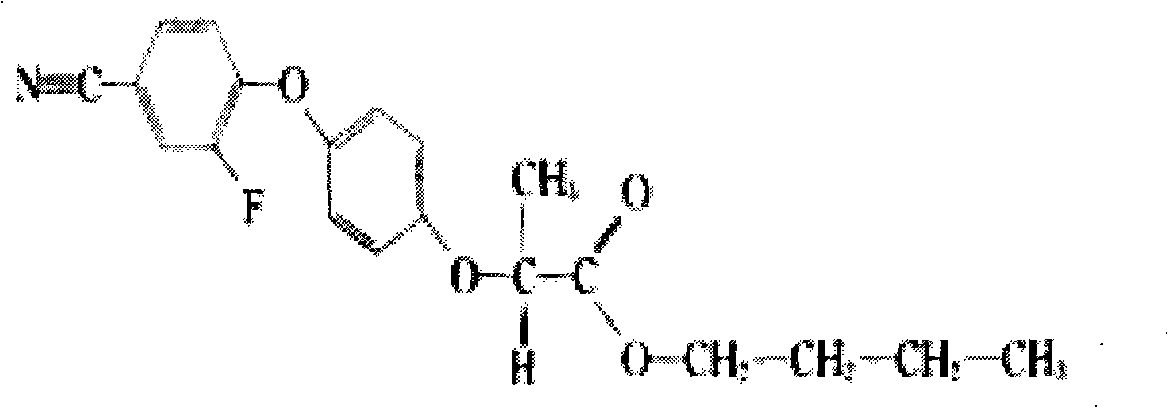

Cyhalofop-butyl microemulsion and preparation method thereof

A technology of cyhalofop-butyl and microemulsion, which is applied in the field of pesticide and herbicidal microemulsion, can solve the problems of environmental pollution, waste of resources, large usage amount, etc., and achieve the effects of reducing environmental pollution, reducing resource consumption and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of cyhalofop-ethyl microemulsion and preparation method thereof, it first prepares 2 kilograms of the original medicine of cyhalofop-methyl, 5 kilograms of dimethylformamide, 2 kilograms of n-butanol, nonionic surfactant, anionic surfactant 4 kg as raw material. Then add all the dimethylformamide and n-butanol into the stirring reaction kettle and mix evenly, then add the cyhalofop-ethyl raw material and mix and stir for about 1 hour, and the rotation speed is controlled at 50 rpm. Then add nonionic surfactant and anionic surfactant and continue to stir evenly, finally add water to make up to 20 kg, and continue to stir for 1 hour to make it a uniform transparent solution product.

Embodiment 2

[0023] A kind of cyhalofop-ethyl microemulsion and preparation method thereof, it first prepares 1 kilogram of cyhalofop-ethyl technical material, 3 kilograms of dimethylformamide, 3 kilograms of isobutanol, nonionic surfactant, anionic surfactant 3 kg as raw material. Then add all the dimethylformamide and n-butanol into the stirring reaction kettle and mix evenly, then add the cyhalofop-ethyl raw material and mix and stir for about 1 hour, and the rotation speed is controlled at 100 rpm. Then add nonionic surfactant and anionic surfactant and continue to stir evenly, finally add water to make up to 20 kg, and continue to stir for 2 hours to make it a uniform transparent solution product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com