Method for purifying molybdenum disulfide by leaching molybdenum concentrate with chlorate

A molybdenum disulfide and molybdenum concentrate technology, applied in the direction of molybdenum sulfide, can solve the problems of high chemical consumption and energy consumption, high toxicity of cyanide, difficult to promote, etc., to reduce pollution, reduce waste discharge, and improve leaching. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The content of each main component of molybdenum concentrate used is as follows:

[0034] Element type

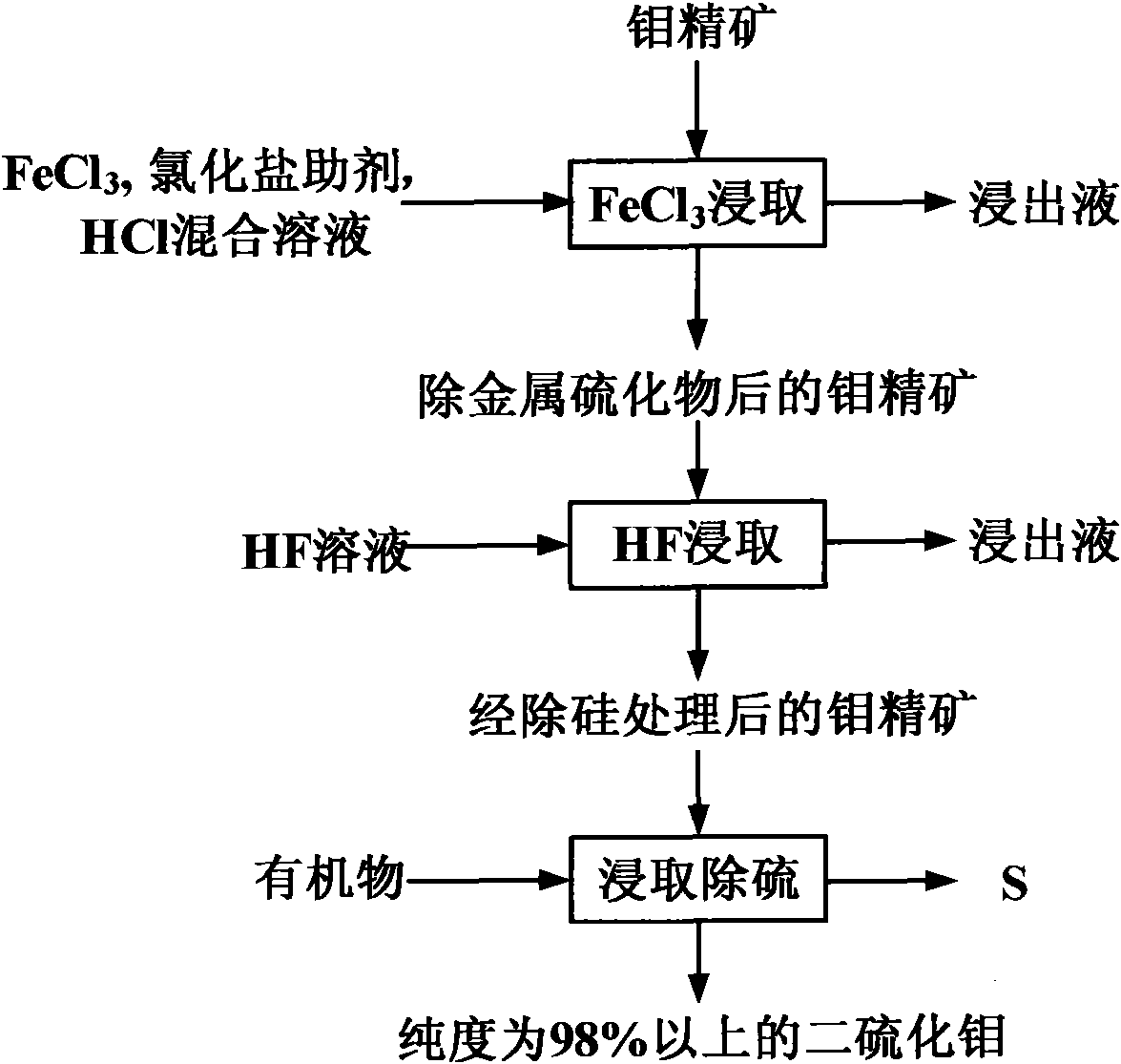

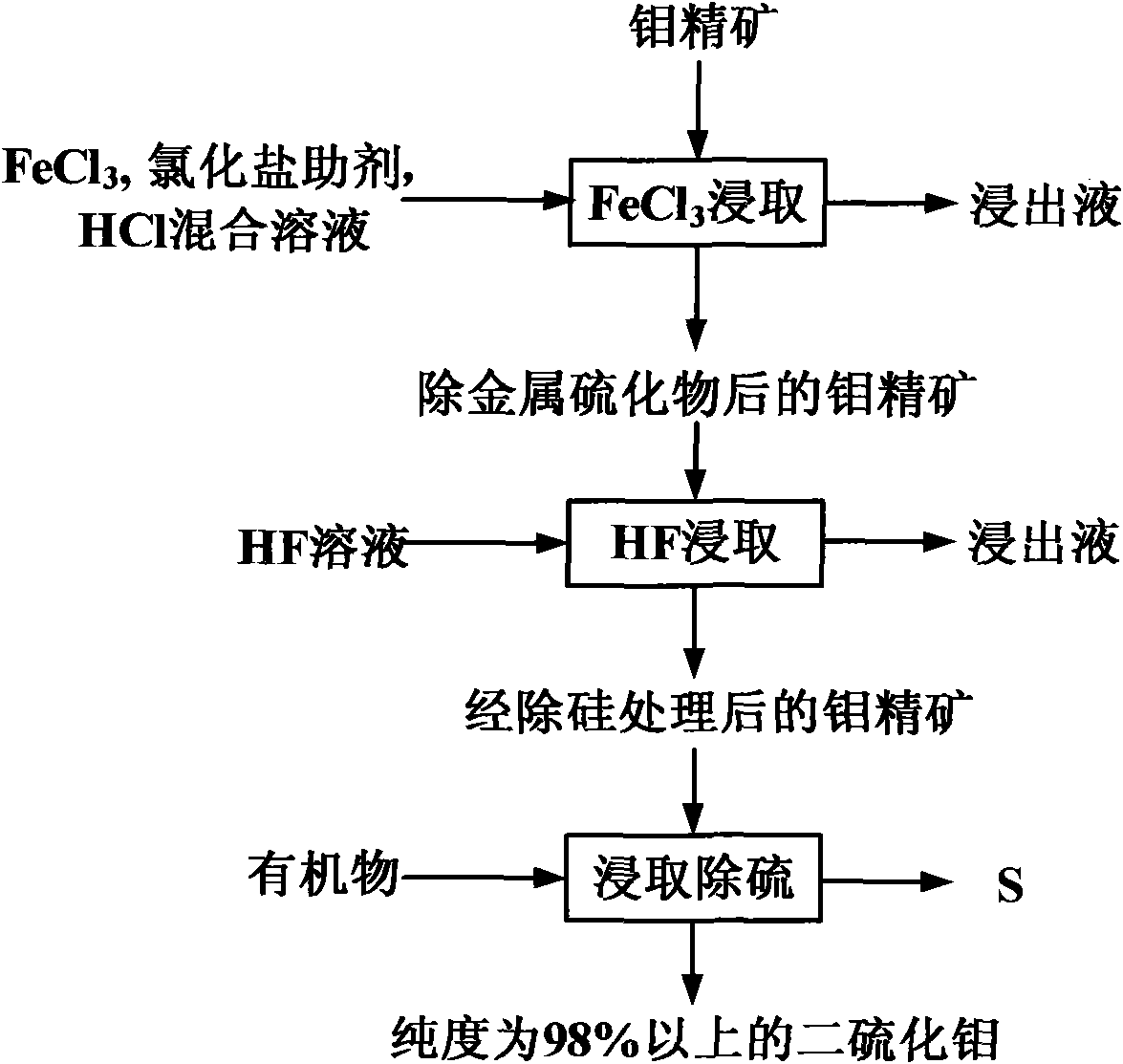

[0035] See figure 1. First prepare 300ml of an aqueous solution containing ferric chloride 300g / L and ferrous chloride 100g / L, add a small amount of hydrochloric acid to adjust the pH value of the aqueous solution to 0 to obtain a leaching solution. Add 30g of molybdenum concentrate into the leach solution for leaching (solid-to-liquid ratio is 1:10), heat to keep the temperature at 110°C, and keep the rotating speed of the stirring blade at 300rpm. Leach for 10 hours to remove metal sulfide impurities (CuS, FeS 2 and CuFeS 2 etc.), then cool and filter, and wash the leached molybdenum concentrate solid 2 to 3 times with hot water at 30°C to remove the chloride adsorbed on the surface of the molybdenum concentrate. Then the molybdenum concentrate obtained after the leaching process is added in the hydrofluoric acid solution of 200ml, wherein, the molar ...

Embodiment 2

[0036] Embodiment 2 (used molybdenum concentrate is identical with embodiment 1)

[0037] See figure 1 . First configure 75ml of an aqueous solution containing ferric chloride 100g / L, calcium chloride 300g / L, and copper chloride 10g / L, and add a small amount of hydrochloric acid to adjust the pH value of the aqueous solution to 1 to obtain a leaching solution. Add 30g of molybdenum concentrate into the leach solution for leaching (solid-to-liquid ratio is 1:2.5), heat to keep the temperature at 90°C, and keep the rotating speed of the stirring blade at 200rpm. Leach for 4 hours to remove metal sulfide impurities (CuS, FeS 2 and CuFeS 2 etc.), then cool and filter, and wash the leached molybdenum concentrate solid 2 to 3 times with hot water at 60°C to remove the chloride adsorbed on the surface of the molybdenum concentrate. Then the molybdenum concentrate obtained after the leaching process is added in the hydrofluoric acid solution of 300ml, wherein, the molar weight of ...

Embodiment 3

[0038] Embodiment 3 (used molybdenum concentrate is identical with embodiment 1)

[0039] See figure 1 . First configure 150ml of an aqueous solution containing ferric chloride 100g / L, ferrous chloride 300g / L, and cupric chloride 10g / L, and add a small amount of hydrochloric acid to adjust the pH value of the aqueous solution to 0 to obtain a leaching solution. Add 30g of molybdenum concentrate into the leach solution for leaching (solid-to-liquid ratio is 1:5), heat to keep the temperature at 120°C, and keep the rotation speed of the stirring blade at 500rpm. Leach for 6 hours to remove metal sulfide impurities (CuS, FeS 2 and CuFeS 2 etc.), then cool and filter, and wash the leached molybdenum concentrate solid 2 to 3 times with hot water at 80°C to remove the chloride adsorbed on the surface of the molybdenum concentrate. Then the molybdenum concentrate obtained after leaching treatment is added in the hydrofluoric acid solution of 250ml, wherein, the molar weight of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com