Method for extracting and separating laburnine

A technology of genistein and a separation method, which is applied in directions such as organic chemistry, can solve the problems of long cycle, low genistein content, complicated process, etc., and achieves the effects of low production cost, reduced production cost and rational development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

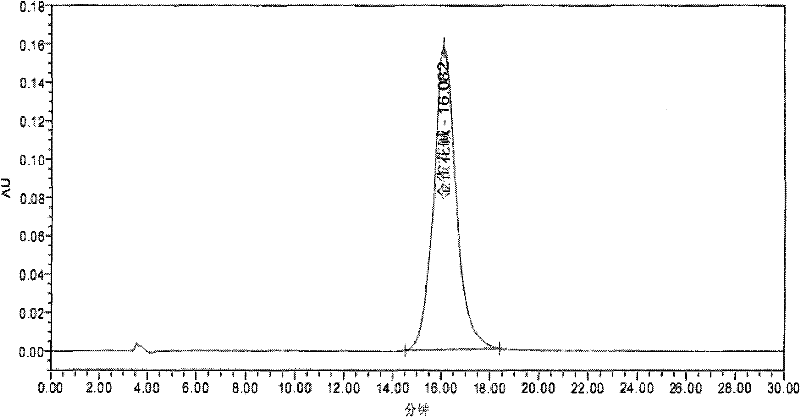

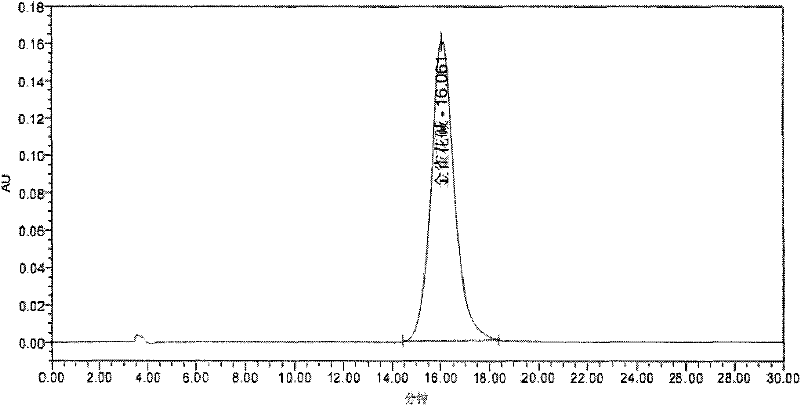

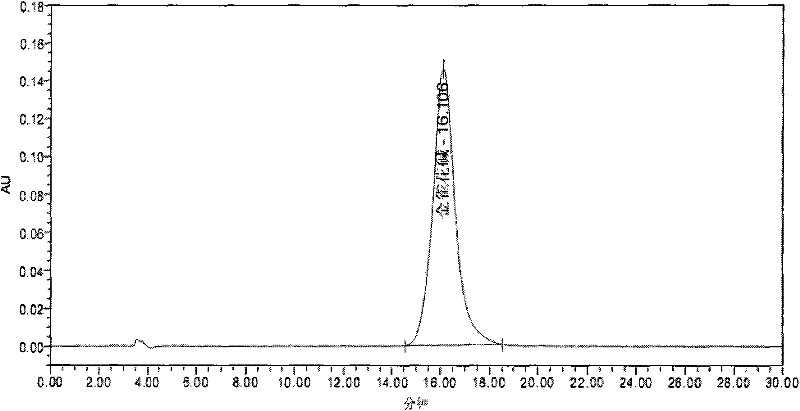

Image

Examples

Embodiment 1

[0051] (1) Extraction: get cytisine content and be that 100kg of the herbivorous bean raw material of 1.2% is pulverized; The raw material of above-mentioned treatment gained is passed through 10 mesh sieves; Then the raw material of gained is 80% with the volume concentration of 5 times of raw material weight The methanol extraction, the extraction temperature is 60 ° C, extraction 3 times, each extraction 2 hours, to obtain the extract;

[0052] (2) Concentration: the extracts are combined, concentrated under reduced pressure until there is no alcohol smell, and a concentrated solution is obtained;

[0053] (3) Alkali adjustment: adding mass concentration to the concentrated solution is 5% sodium hydroxide solution to make the pH=10 of the concentrated solution;

[0054] (4) Extraction: extract the concentrated solution obtained through the treatment of step (3) with ethyl acetate to obtain an extract; the number of extractions is 3 times, and the volume of the extraction so...

Embodiment 2

[0072] (1) Extraction: get cytisine content and be that 100kg of Sophora sophora raw material of 0.6% is pulverized; The raw material of above-mentioned treatment gained is passed through 20 mesh sieves; Then the raw material of gained is 60% with the volume concentration of 6 times of raw material weight. Methanol extraction, the extraction temperature is 80°C, extraction 3 times, each extraction 1.5 hours, to obtain the extract;

[0073] (2) Concentration: the extracts are combined, concentrated under reduced pressure until there is no alcohol smell, and a concentrated solution is obtained;

[0074] (3) Alkali adjustment: add strong ammonia water to the concentrated solution to make the concentrated solution pH=9;

[0075] (4) Extraction: extract the concentrated solution obtained through the treatment of step (3) with dichloromethane to obtain an extract; the number of extractions is 2 times, and the volume of the extraction solvent is 4 times the volume of the concentrated...

Embodiment 3

[0093] (1) Extraction: get cytisine content and be that 100kg of Sophora alopecuroides raw material of 0.56% is pulverized; The raw material of above-mentioned processing gained is passed through 20 mesh sieves; Then the raw material of gained is 90% with the volume concentration of 4 times of raw material weight. Ethanol extraction, extraction temperature is 75°C, extraction is 3 times, each extraction takes 1.5 hours to obtain extract;

[0094] (2) Concentration: the extracts are combined, concentrated under reduced pressure until there is no alcohol smell, to obtain a concentrated solution;

[0095] (3) Alkali adjustment: adding mass concentration to the concentrated solution is 10% potassium hydroxide to make the concentrated solution pH=11;

[0096] (4) Extraction: the mixed system that the volume ratio of sherwood oil and ethyl acetate is 1: 3 is extracted with the solution obtained through step (3) processing, obtains extract; The number of times of extraction is 2 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com