Co-catalysis compatibilization modified polystyrene alloy material and preparation method thereof

A polystyrene and compatibilizing modification technology, which is applied in the field of co-catalyzed compatibilizing modified polystyrene alloy materials and the preparation thereof, can solve the problem that the interfacial tension cannot be reduced, the compatibilizer is expensive, and the blending is unfavorable. Processing and other problems, to achieve the effect of improving processing fluidity, easy blending and processing, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

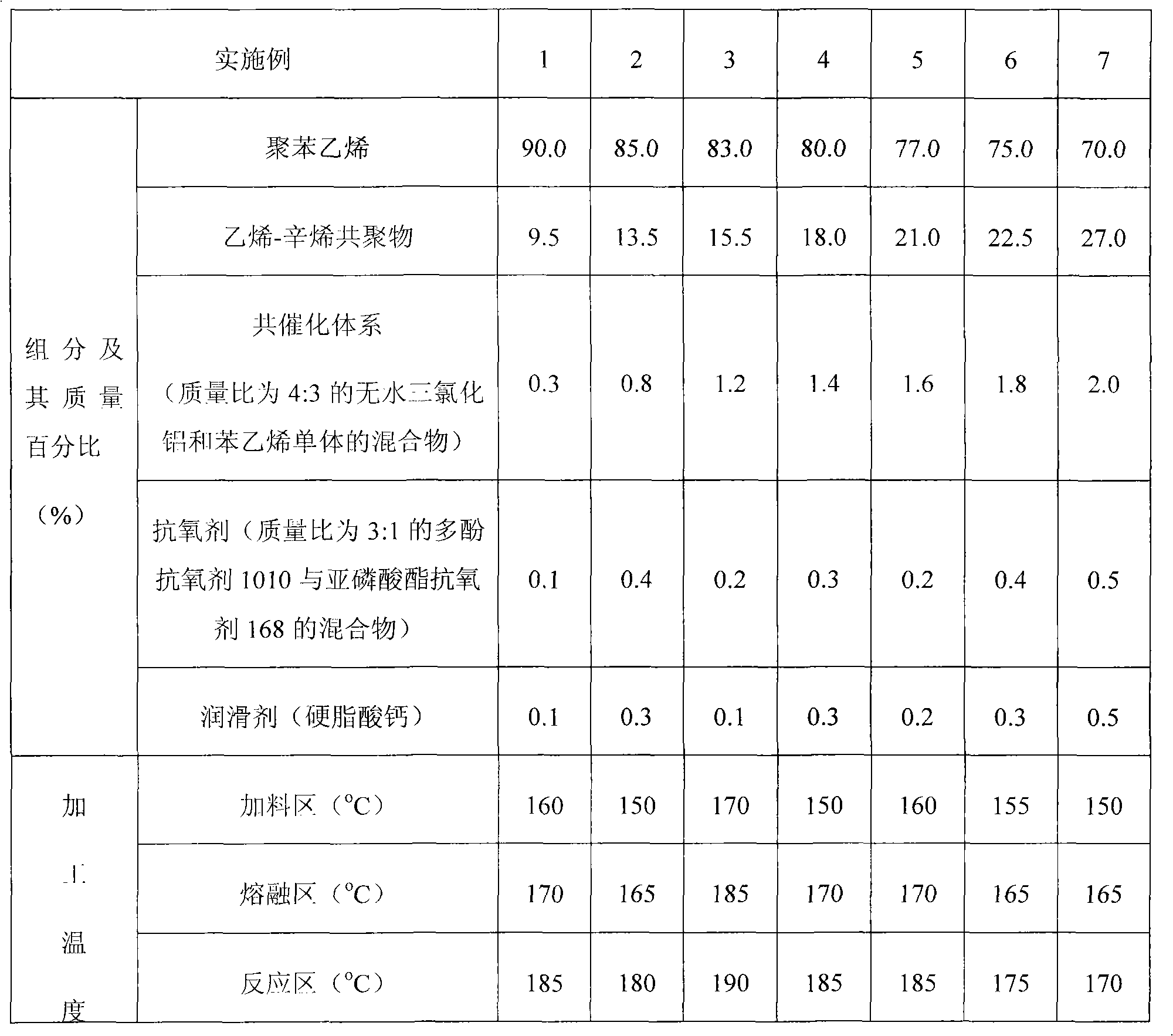

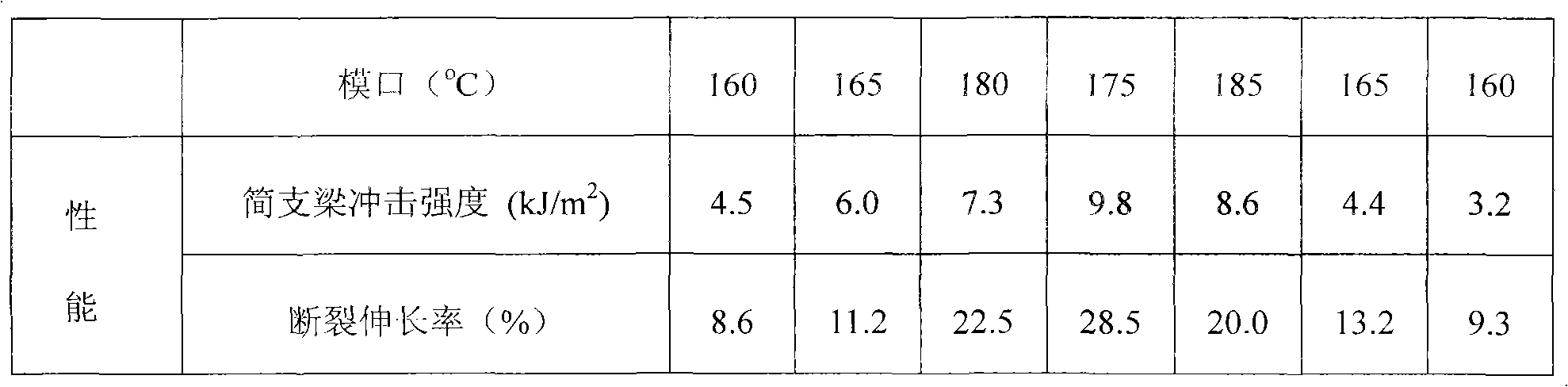

[0020] The preparation steps are as follows: add polystyrene, ethylene-octene copolymer, co-catalyst system, antioxidant, and lubricant into the mixer according to the formula ratio and stir until the materials are mixed uniformly (about 5-10 minutes), and then the mixed The uniform material is transferred to the twin-screw extruder for melting and extrusion. The barrel temperature is: feeding zone 150-170°C, melting zone 165-185°C, reaction zone 170-190°C, die temperature 160-185°C, machine Head pressure: 3-6MPa, screw speed 60-90rpm, the material is extruded and then cooled and granulated to obtain cylindrical granule products. The specific experimental parameters corresponding to each embodiment are shown in the table below:

[0021] The formula, processing temperature and product performance of the co-catalyzed compatibilization modified polystyrene alloy material of the embodiment of the present invention are shown in Table 1 below:

[0022] Table 1 material embodiment 1~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com