Thick oil-degrading bacteria and application thereof

A technology for degrading bacteria and heavy oil, applied in the field of biological treatment of environmental pollutants, to achieve high-efficiency heavy oil removal rate and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

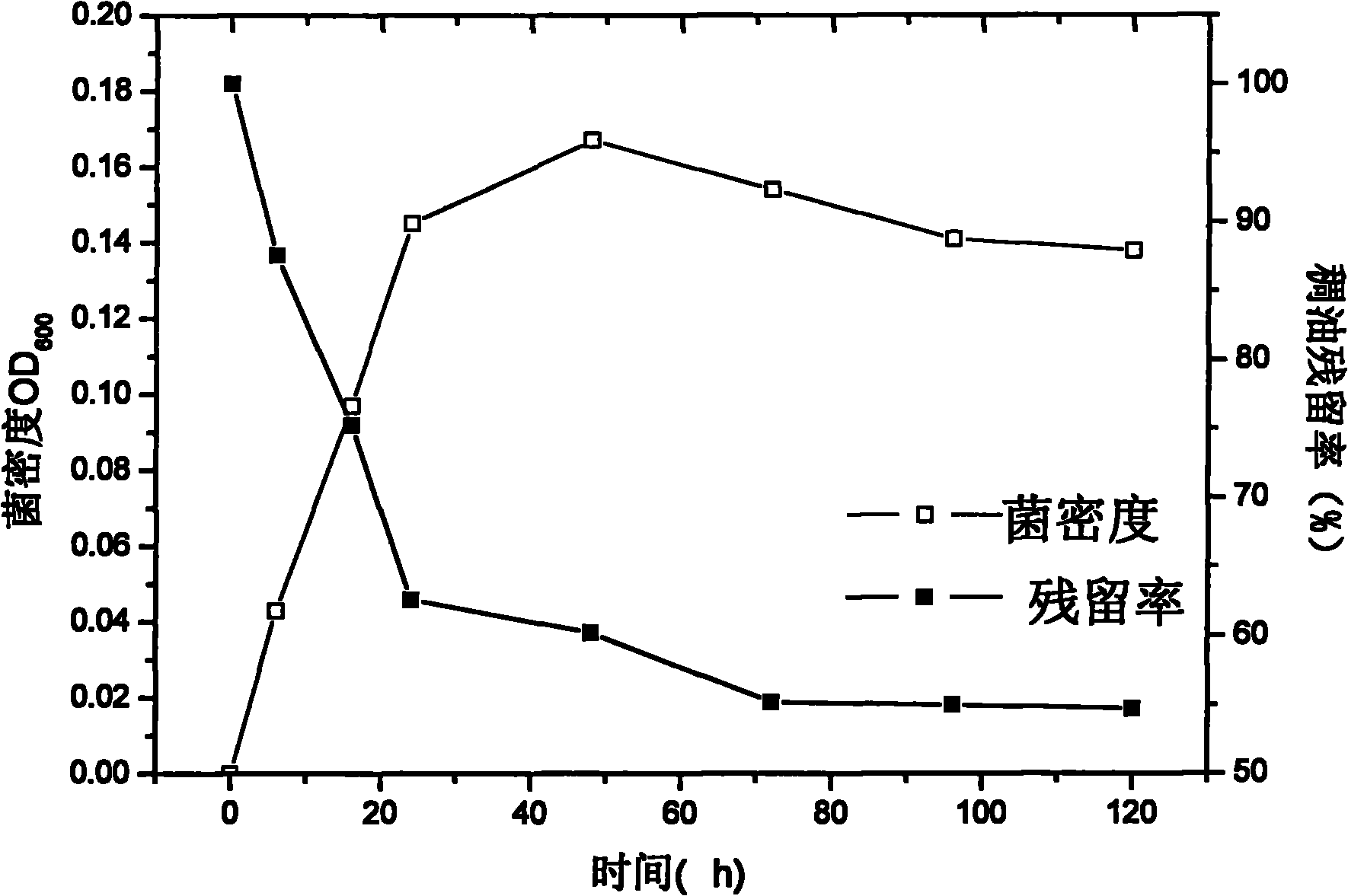

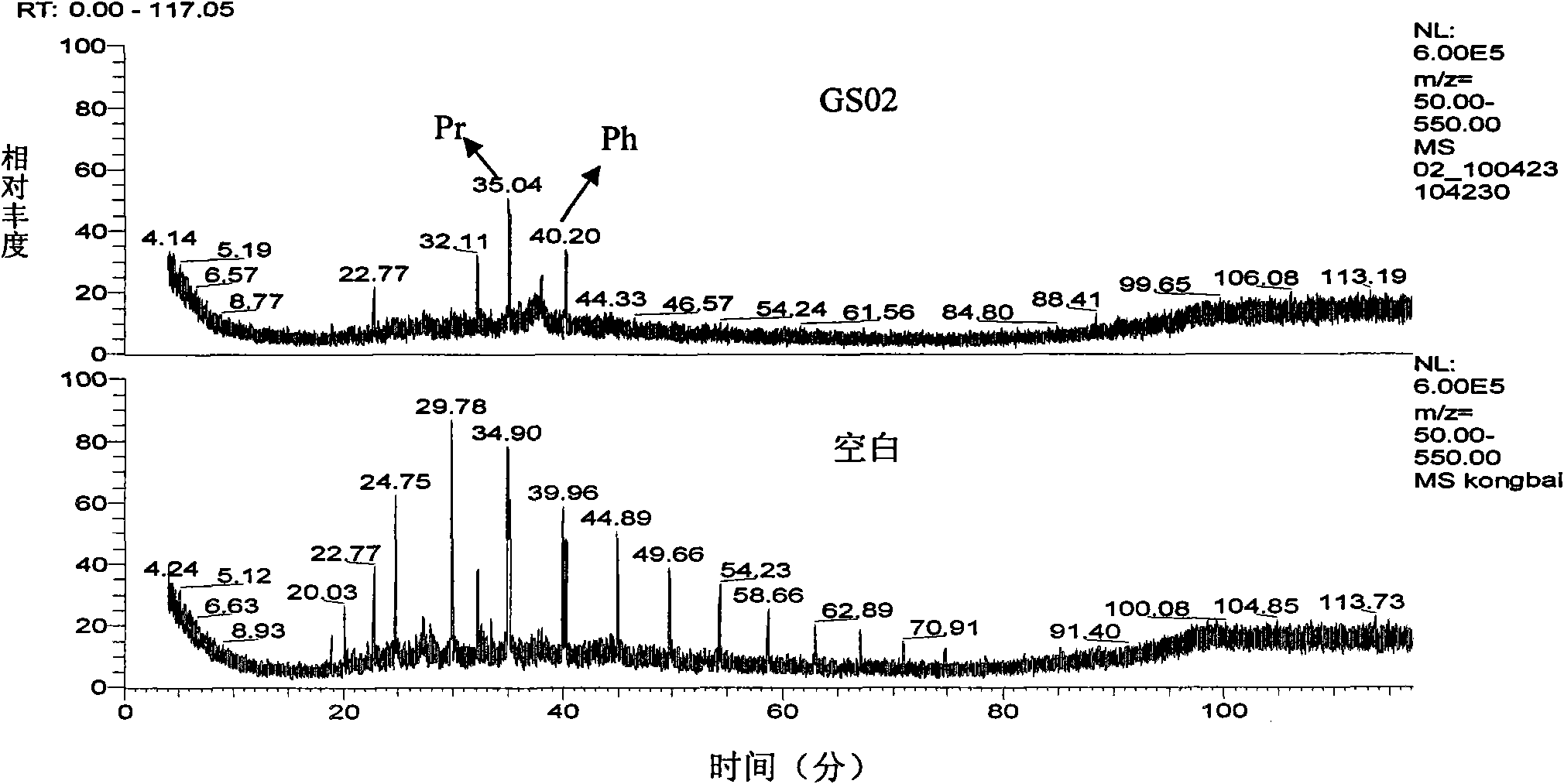

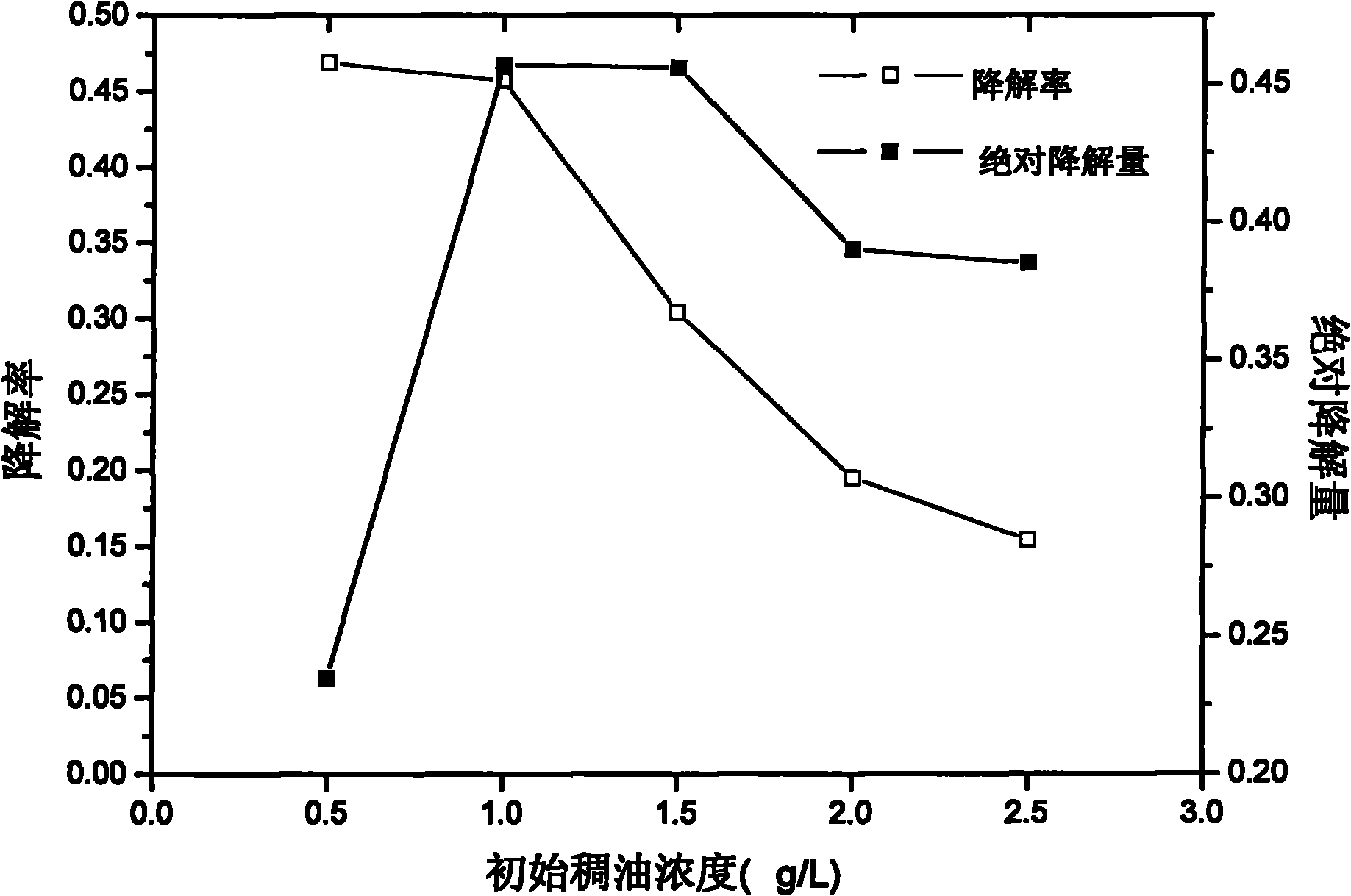

[0023] Screening and Isolation of Strain CCTCC M 2010172 and Its Heavy Oil Degradation Performance

[0024] The mud-water mixture polluted by petroleum hydrocarbons in Guangzhou Petrochemical General Plant was collected on site, and heavy oil-degrading bacteria were acclimated using an inorganic salt liquid culture medium system with heavy oil as the only carbon source. Inorganic salt liquid medium: KH 2 PO 4 0.5g, K 2 HPO 4 ·3H 2 O 1g, NaCl 2g, MgSO 4 Aqueous solution (22.5g / L) 3.0mL, CaCl 2 Aqueous solution (36.4g / L) 1.0ml, FeCl 3 Aqueous solution (0.25g / L) 1.0ml, trace element solution 1.0ml, distilled water 1L. Among them, the trace element solution composition: MnSO 4 ·H 2 O 39.9mg / L, ZnSO 4 ·H 2 O42.8mg / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 34.7mg / L. The initial concentration of heavy oil is 1g / L. After several generations of repeated acclimatization, streak culture in solid medium (NR) to obtain multiple strains of pure bacteria, spread the pure bacteria on a ...

Embodiment 2

[0029] Effect of Temperature on Degradation of Heavy Oil

[0030] The thick oil inorganic salt liquid medium inoculated with GS02 was placed in a constant temperature shaker at 25, 28, 30, 35 and 40 °C for 6 days, and then the effect of temperature on the degradation of heavy oil was determined.

[0031] Table 1

[0032]

[0033] Temperature (℃) Degradation rate (%)

[0034]

[0035] 25 34.5

[0036] 28 38.7

[0037] 30 45.7

[0038] 35 39.5

[0039] 40 27.4

[0040]

[0041] It can be seen from Table 1 that the degrading bacteria GS02 has a certain removal effect on heavy oil in the range of 25-35 °C, and the degradation effect is the best at 30 °C, which is 45.7%. In the wide temperature range of 25-35 °C, the degradation effect does not change significantly. When the temperature reaches 40°C, the degradation rate decreases, which is because the protein in the bacterial cell is ...

Embodiment 3

[0044] Effect of pH Value on Degradation of Heavy Oil

[0045] The pH value of the inorganic salt liquid medium was adjusted to 6.5, 7.0, 7.2, 7.5 and 8.0 respectively, and the initial concentration of heavy oil was 1g / L, and cultured for 6 days to determine the effect of pH value on the degradation of heavy oil.

[0046] Table 2

[0047]

[0048] pH degradation rate (%)

[0049]

[0050] 6.5 31.5

[0051] 7.0 45.7

[0052] 7.2 47.6

[0053] 7.5 38.3

[0054] 8.0 34.9

[0055]

[0056] As can be seen in Table 2, when the pH value is 7.2, the degrading bacteria GS02 has the strongest degradation effect on heavy oil, and the degradation rate can reach 47.6% in 6 days; when the pH value is 6.5, the degradation rate is lower, 31.5%. The pH value mainly affects the activity of bacterial enzymes, the permeability and stability of the plasma membrane, thus affecting the degradation rate of petro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com