Sectional cylinder cut tobacco dryer

A drum dryer and segmented technology, which is applied in the directions of tobacco preparation, application, tobacco, etc., can solve the problems of affecting the uniformity of tobacco drying, reducing drying efficiency, wasting heat, etc., to meet the processing strength and drying uniformity. , The temperature is uniform and stable, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

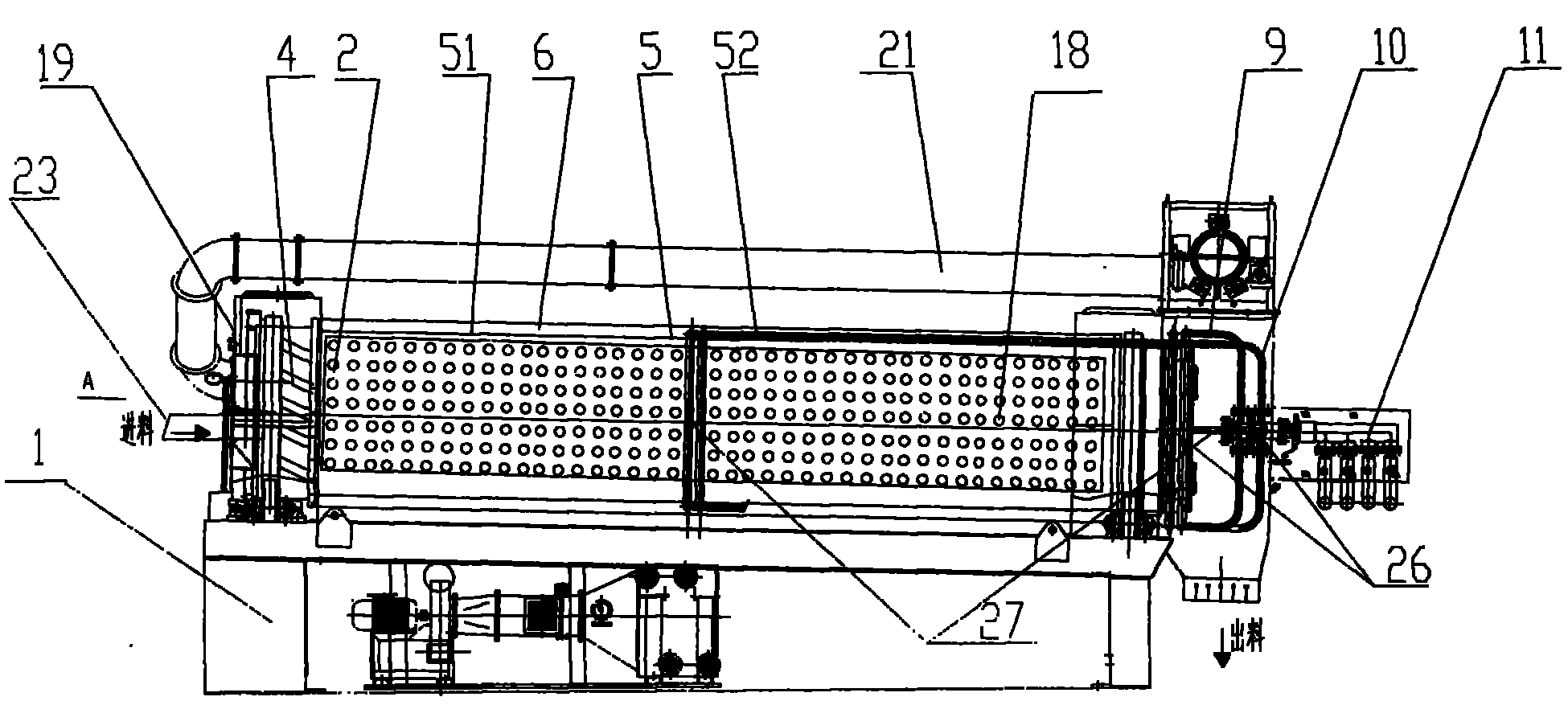

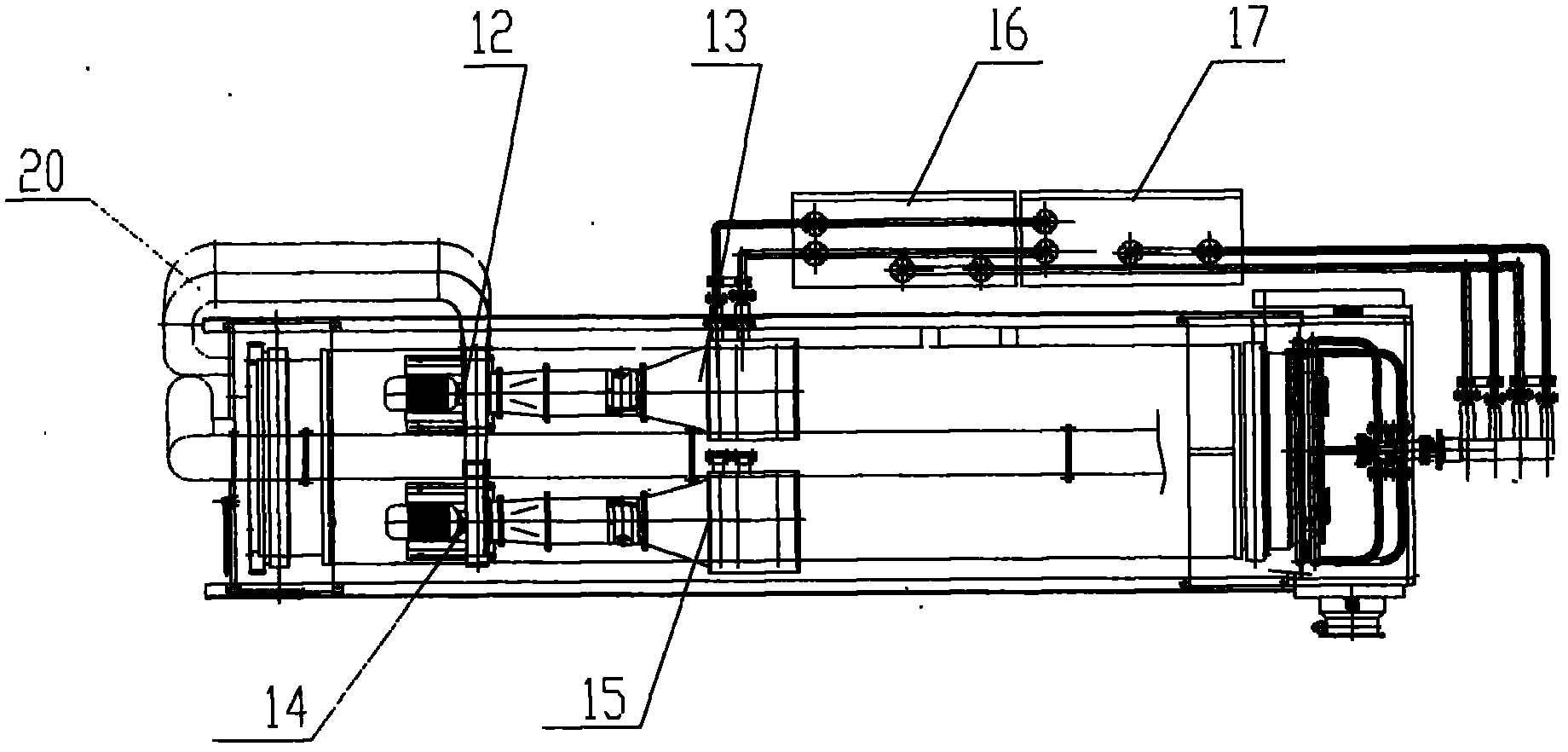

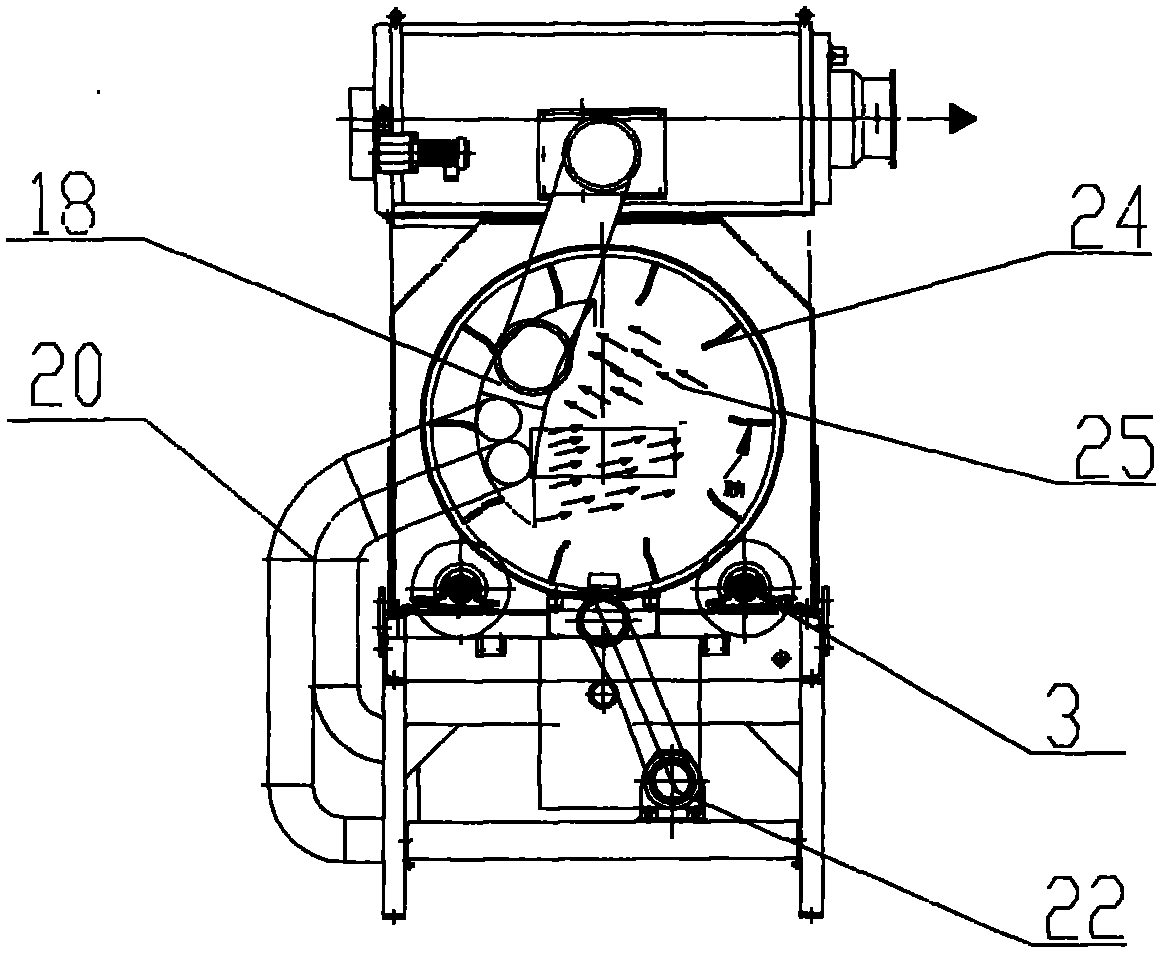

[0025] Such as figure 1 , figure 2 and image 3 As shown, the segmented drum silk drying machine of the present invention includes a bracket 1, which is the support of all parts of the drum silk drying machine, and the drum 2 with a certain inclination (generally at 1.5°-3°) is installed on the front and rear sides. On the set of support rollers 3, the drum 2 includes the material guide cylinder 4, the drying cylinder 5 equipped with heat exchange plates, the insulation layer 6, and the heat transfer oil inlet ring pipe 9 of the drying cylinder in the feeding section, and the drying cylinder in the discharging section. Heat transfer oil inlet ring pipe 10, rotary joint 11, etc. The fan 12 and heat exchanger 13 of the dryer hot air system in the feed section and the fan 14 and heat exchanger 15 of the dryer hot air system in the discharge section are installed below the drum 2, and the heat transfer oil circulating oil temperature controller 16 passes through the pipeline. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com