LDH catalyst for Tishchenko reaction and preparation method thereof

A catalyst, anionic clay technology, applied in the field of pillared hydrotalcite (LDH) catalyst and its preparation, can solve the problems of less by-products, equipment corrosion, more by-products, etc., and achieve less by-products, less equipment corrosion, and by-products less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

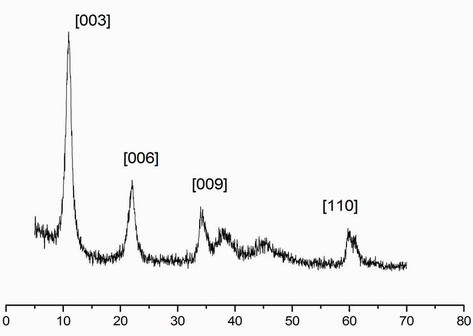

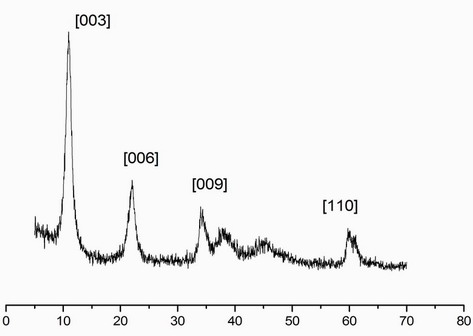

Image

Examples

Embodiment 1

[0022] The preparation method of the layered magnesium aluminum anion clay catalyst supported by tert-butoxy anion pillar comprises the following steps:

[0023] (1) Magnesium aluminum anion clay (MgAl-HT-NO 3 ) preparation

[0024] In a reaction kettle with a thermometer, a stirrer and a dropping funnel, under nitrogen protection, 30.8g (0.12mol) Mg(NO 3 ) 2 ·6H 2 0 and 15.0 g ( 0.04 mol) Al(NO 3 ) 3 9H 2 0 Dissolve completely in 100 mL of CO removal 2 deionized water; at room temperature and under stirring conditions, add 2 M NaOH solution dropwise, control the pH value of the slurry at about 10 during the dropping process, and keep the dropping time at about 1 h; continue stirring for 2 h after the dropping . After the reaction, carry out vacuum filtration, and wash the obtained filter cake with water until the filtrate is neutral; the washed filter cake is vacuum-dried at 80°C for 10 h to obtain about 15.2 g of magnesium-aluminum anion clay, marked as MgAl- HT-NO ...

Embodiment 2

[0028] The preparation method of the layered magnesium aluminum anion clay catalyst supported by tert-butoxy anion pillar comprises the following steps:

[0029] (1) Magnesium aluminum anion clay (MgAl-HT-NO 3 ) preparation

[0030] In a reaction kettle with a thermometer, a stirrer and a dropping funnel, under nitrogen protection, 30.8g (0.12mol) Mg(NO 3 ) 2 ·6H 2 0 and 12.8 g ( 0.035 mol) Al(NO 3 ) 3 9H 2 0 Dissolve completely in 100 mL of CO removal 2 deionized water; at room temperature and under stirring conditions, add 2 M NaOH solution dropwise, control the pH value of the slurry at about 10 during the dropping process, and keep the dropping time at about 1 h; continue stirring for 2 h after the dropping . After the reaction, carry out vacuum filtration, and wash the obtained filter cake with water until the filtrate is neutral; the washed filter cake is vacuum-dried at 80°C for 10 h to obtain about 14.7 g of magnesium-aluminum anion clay, marked as MgAl- HT-NO...

Embodiment 3

[0034] Using the layered magnesium-aluminum anion clay supported by tert-butoxy anion pillars obtained in Example 1 as a catalyst for the Jishchenko reaction, catalyzed synthesis of 2,2,4-trimethyl-1,3-pentanediol monoisobutyric acid ester, comprising the following steps:

[0035] 1) Isobutyraldehyde condensation reaction

[0036] In a reaction kettle with a thermometer, a reflux condenser and a constant pressure dropping funnel, under nitrogen protection, normal pressure, and 20°C, add 30 g of NaOH solution with a mass concentration of 2-5%, and continuously and slowly Add 90 g of isobutyraldehyde dropwise for 1 hour; after the dropwise addition, continue to react at 35°C for 4 hours; after stopping the reaction, let the layers stand for 2-3 hours, and after separation, the upper layer is an oil layer, wash with water until neutral , followed by 5 g of anhydrous MgSO 4 Drying yields a dry isobutyraldehyde condensation product. The lower layer is the water layer, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com