Preparation method of lignin metal element chelate fertilizer and device thereof

A metal element, lignin technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as limited chelation capacity, and achieve the effects of strong chelation capacity, increased content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

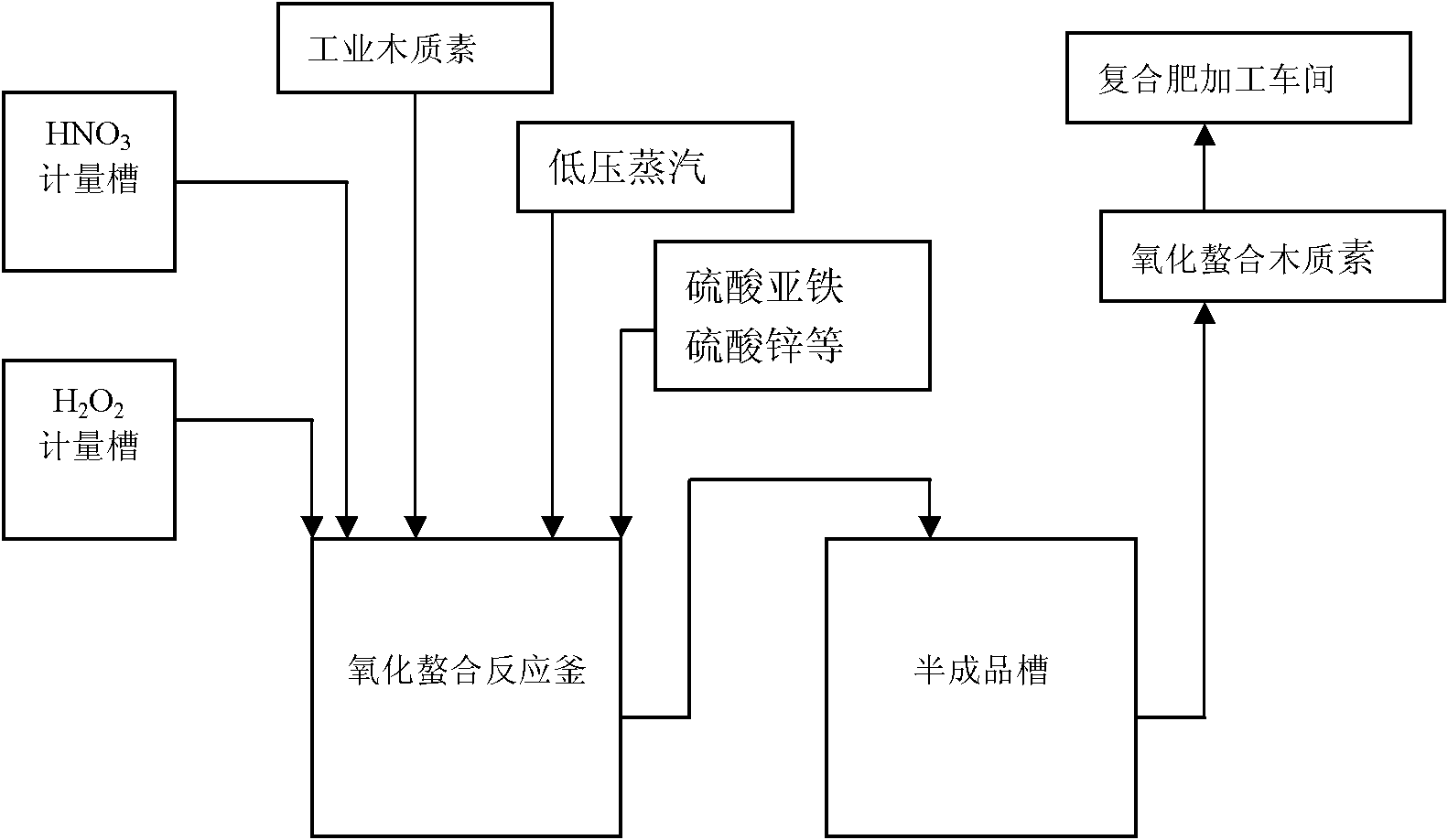

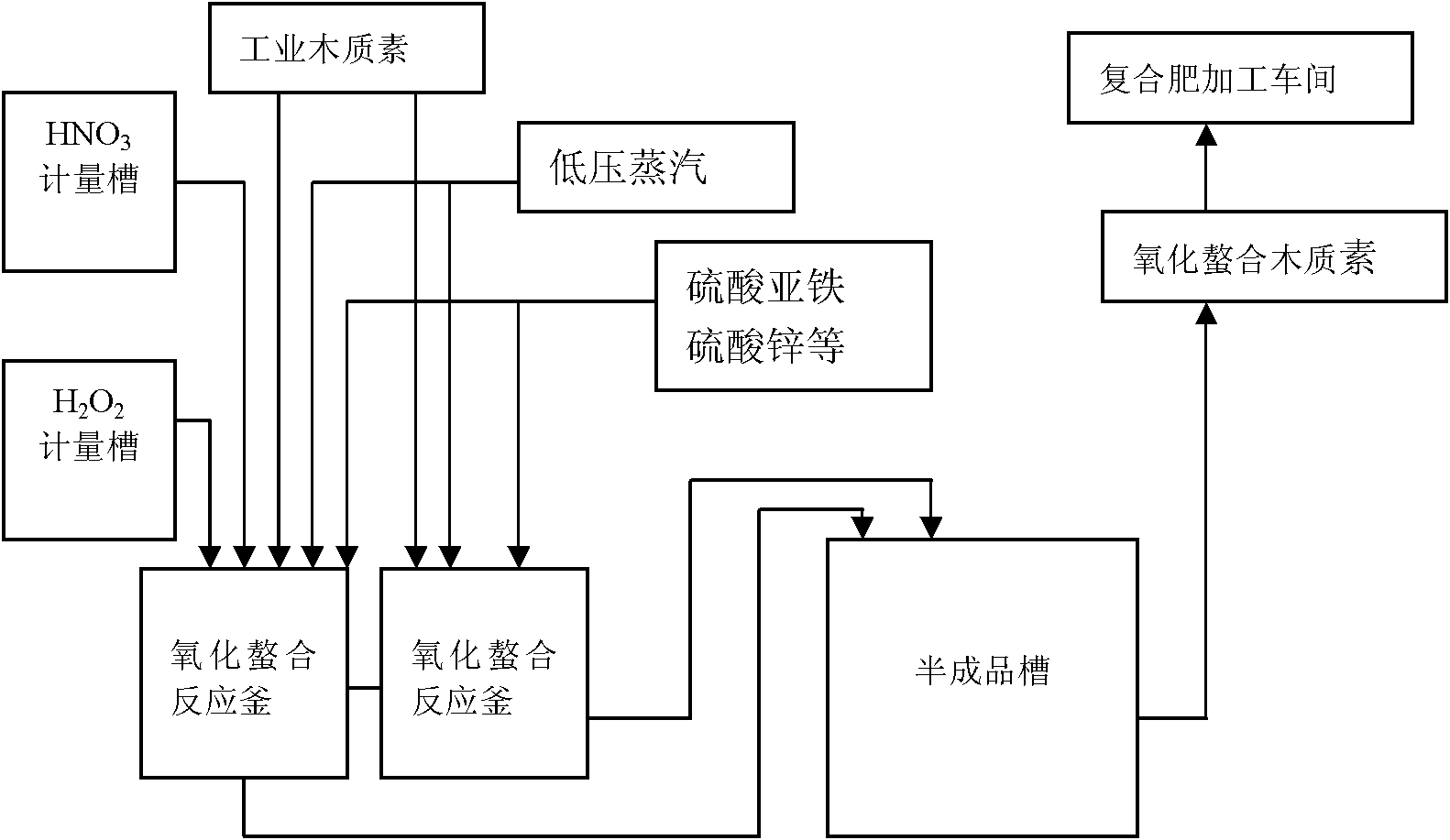

[0032] Below in conjunction with accompanying drawing, the preparation method of lignin chelated fertilizer is further described,

[0033] Such as figure 1 , the industrial lignin salt is configured into an aqueous solution of a certain concentration in the dissolving tank; the configured industrial lignin aqueous solution is transferred to the reactor; (2) nitric acid is introduced from the nitric acid metering tank to adjust the pH value of the solution; (3) from hydrogen peroxide (H 2 o 2 ) into the metering tank, introduce ferrous sulfate from the initiator metering tank, start the stirring device of the reaction vessel such as zinc sulfate, add the inorganic salt containing medium and trace metal elements after fully mixing; (4) after heating to a certain temperature Respond to the specified time.

[0034] The reacted oxidized chelate is sent to the semi-finished product tank for further processing, and finally the obtained oxidized chelated lignin is sent to the compo...

Embodiment 1

[0037] The present invention describes the preparation method of lignin salt-metal element chelate fertilizer and the equipment used by taking lignin iron salt as an example;

[0038] Experimental raw materials: lignin ammonium salt was obtained from a paper mill in Anhui; alkali lignin was obtained from a paper mill in Shandong.

[0039] Lignin ammonium salt and FeSO 4 The chelation process:

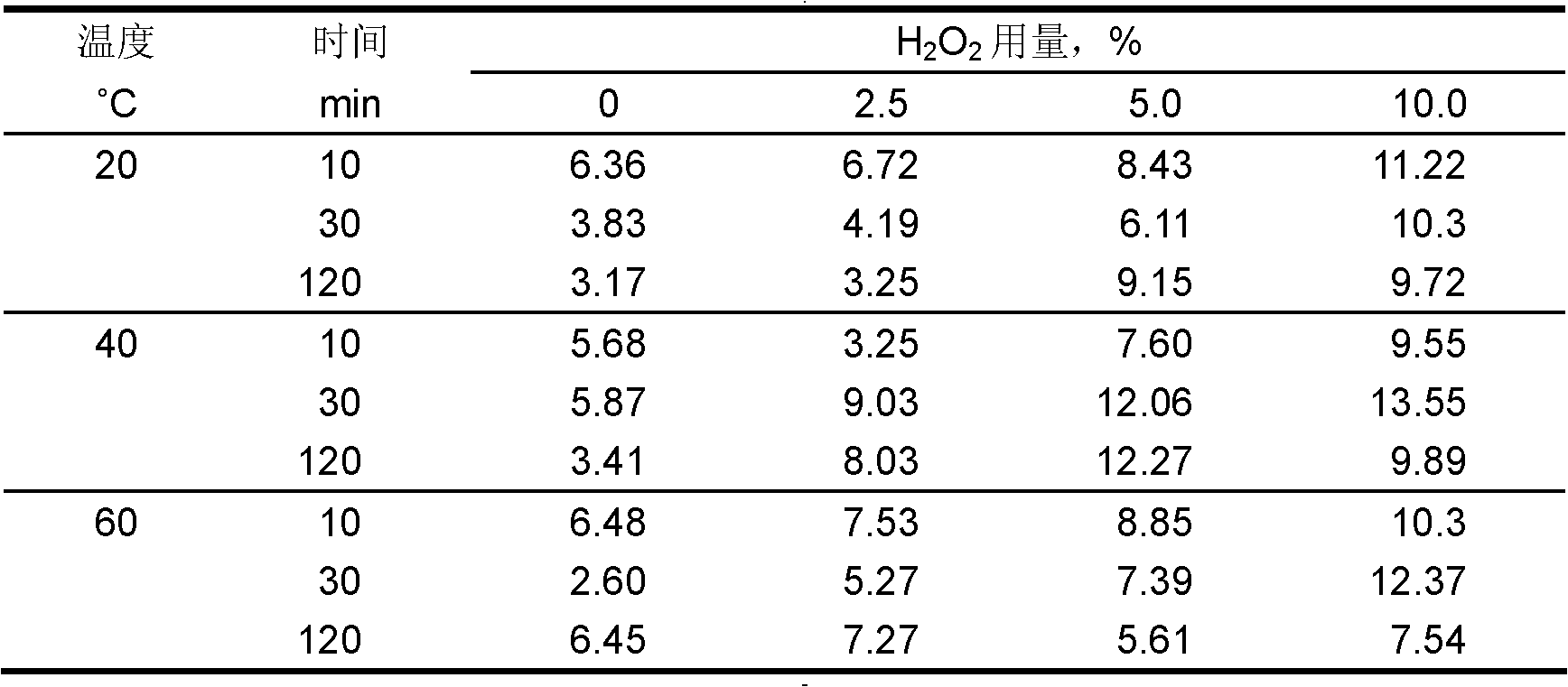

[0040] This study mainly investigates the excess FeSO 4 In the presence of conditions, H 2 o 2 Effects of dosage, reaction temperature and reaction time on the chelation of lignin ammonium salt and Fe element. FeSO in the reaction system 4 The mass ratio to lignin ammonium salt is 2:3, H 2 o 2 The dosage (based on lignin ammonium salt) is 0%, 2.5%, 5% and 10% respectively, the reaction time is 10min, 30min and 120min respectively; the reaction temperature is 20°C, 40°C and 60°C respectively. By comparing the chelation rate of Fe element in the product under different reaction co...

Embodiment 2

[0052] The present invention describes the preparation method of lignin salt-metal element chelate fertilizer and the equipment used by taking lignin salt as an example;

[0053] Preparation of lignin ammonium salt-Zn element chelate

[0054] Lignin ammonium salt and ZnSO under acidic conditions 4 The reaction prepares lignin ammonium salt-zinc element chelate. During the reaction, add excess ZnSO to the lignin ammonium salt solution 4 (ZnSO 4 The addition amount is 50% of lignin ammonium salt), then add trace FeSO 4 to trigger a reaction. React at a certain temperature for a specified time, and add NaOH solution to adjust the pH to 12. At this time, the excess Zn 2+ React with NaOH to form Zn(OH) 2 Precipitation, centrifugation to remove the precipitate, the liquid part is the lignin ammonium salt-zinc chelate, and the zinc content in it is the zinc chelated with the lignin ammonium salt. By measuring the content of zinc chelated with lignin ammonium salt, the chelatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com