Electrical discharge coating method and green compact electrode used therein

A technology of pressed powder and electrode, which is applied in transportation and packaging, welding medium, coating, etc. It can solve the problems of longer reaction time, difficulty in migration of electrode materials and their carbides, and inability to achieve thick film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

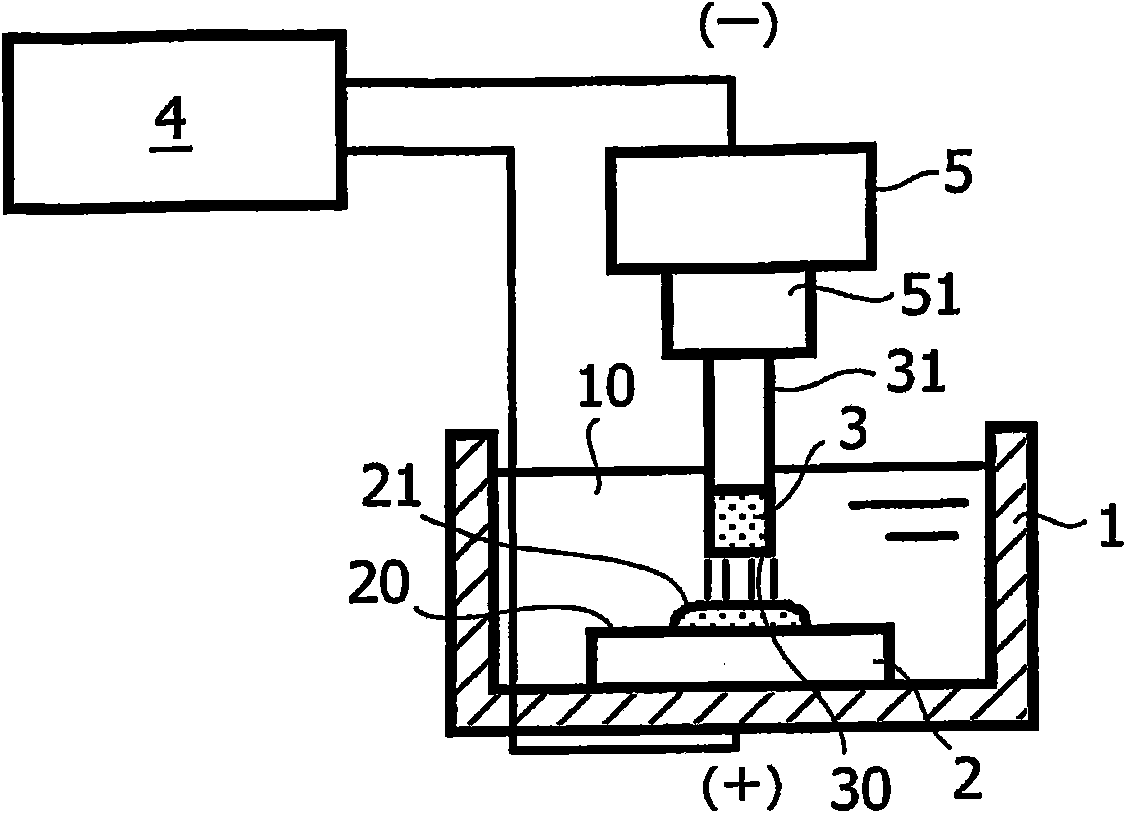

Method used

Image

Examples

Embodiment

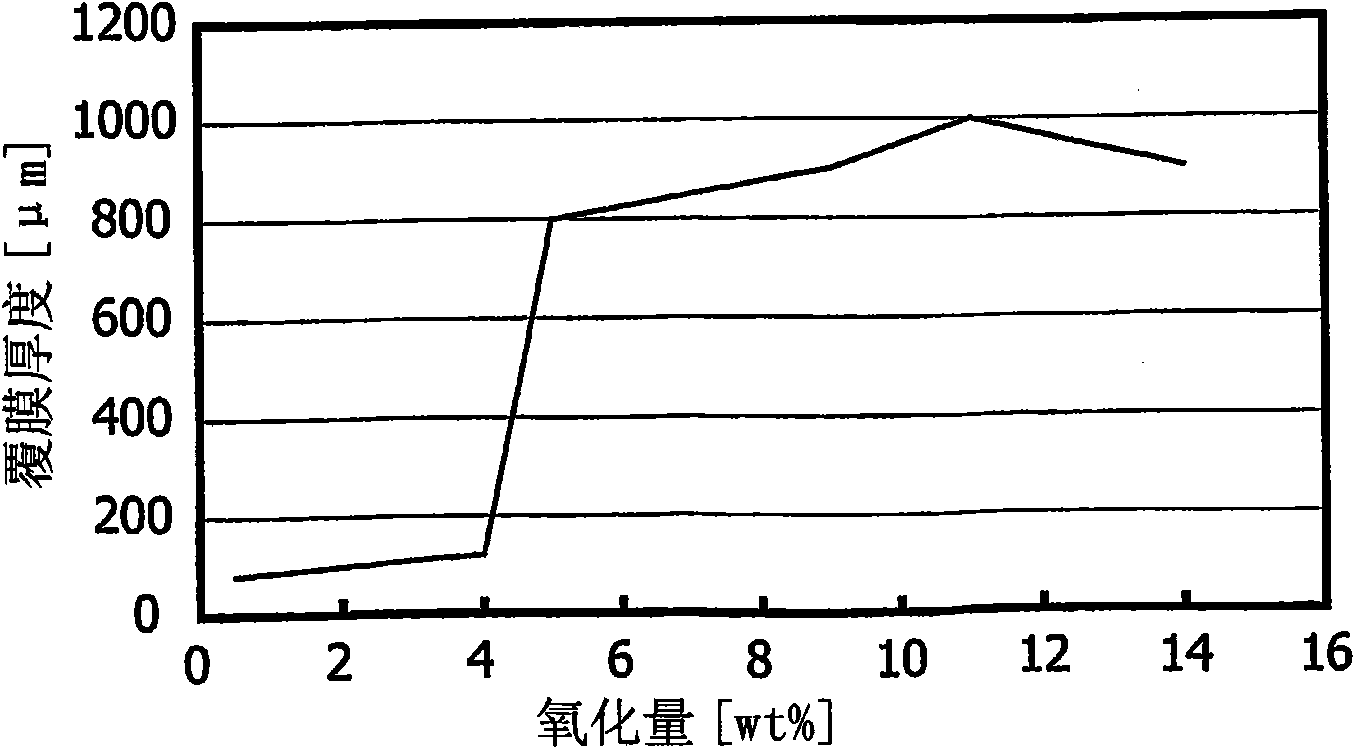

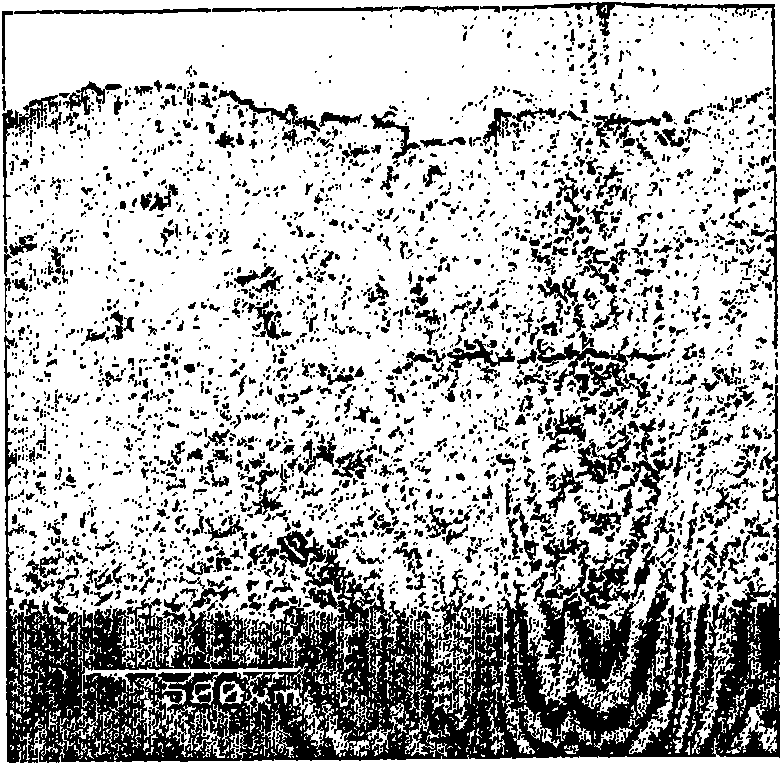

[0060] In order to verify the effect of the oxide layer on the surface of the above metal powder on the film thickness, the following experiments were carried out: the formation conditions and discharge conditions of the compact electrode were not changed, but only the oxidation amount of the metal powder was changed, and the surface of the aluminum material and the surface of the magnesium material were respectively tested. , The surface of the titanium material is subjected to discharge coating processing, and the film thickness change at this time is investigated.

[0061] In the experiment carried out on the surface of aluminum materials, molybdenum powder with an average particle size of 2 μm was used as metal powder, and oxidation treatment was carried out at 250°C in the atmosphere, so that the oxidation amount varied from 3wt% to 14wt%, respectively at 400Mpa 13.8mm in diameter to make cylindrical powder compacts with a diameter of 13.8mm, and use them as negative elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com