Method for preparing feed by mixing straw and butanol or alcoholic fermentation waste water

A technology of ethanol fermentation and straw, applied in animal feed, animal feed, additional food elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

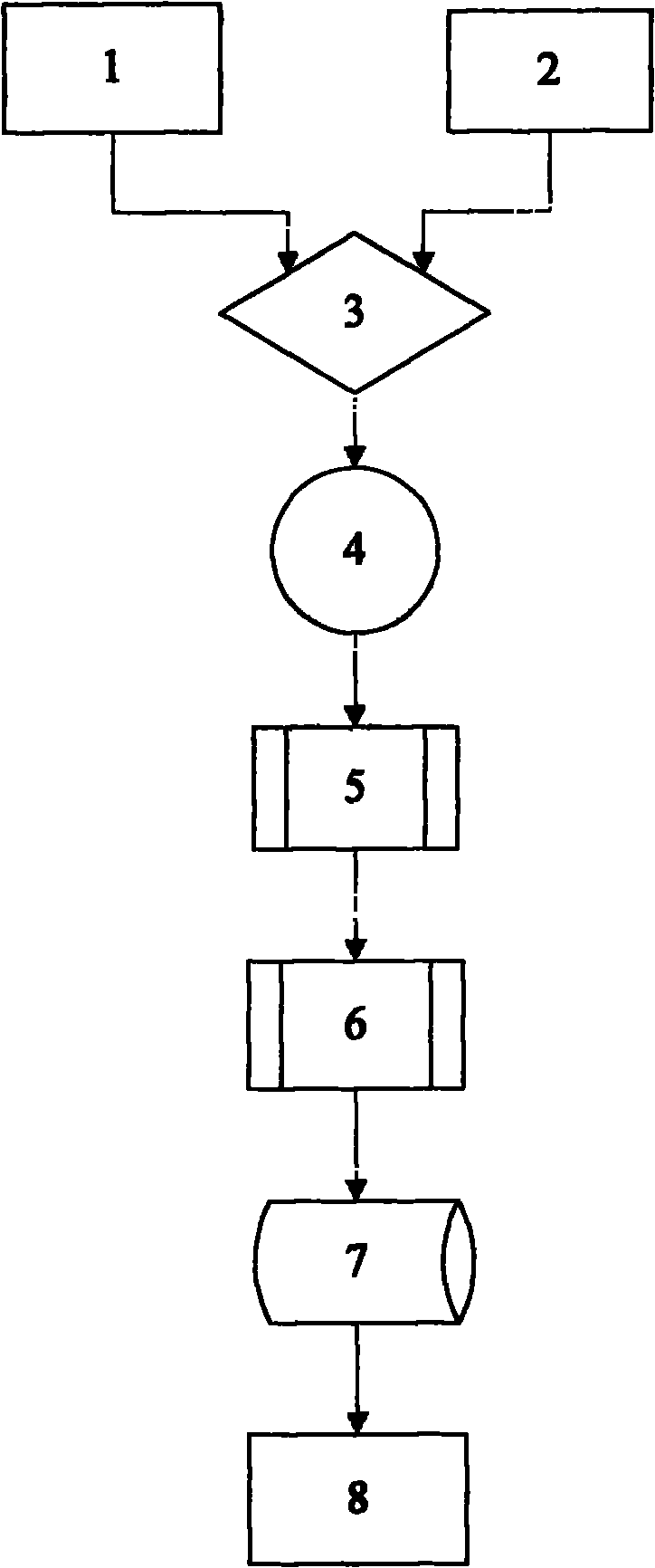

Method used

Image

Examples

Embodiment 1

[0014] (1) Straw steam explosion: Cut the collected corn stalks into 4-5cm, mix them with dilute acid hydrolyzed five-carbon sugar butanol fermentation wastewater of straw at a ratio of 1:0.8 (w / w), put them into a steam explosion tank, and Keep the pressure under pressure for 5 minutes for steam explosion treatment;

[0015] (2) Butanol fermentation waste liquid is mixed with steam-exploded straw: after the straw is steam-exploded, it is mixed with a certain volume of waste water after butanol fermentation and distillation of dilute acid hydrolyzed five-carbon sugar of straw, so that the moisture content is 75%;

[0016] (3) Solid-state fermentation: sterilize the mixture of straw dilute acid hydrolyzed five-carbon sugar butanol fermentation waste liquid and steam-exploded straw into Penicillium recumbens and white rot fungus, the inoculum amounts are 4% and 3% respectively, and the pressure is pulsating in solid state After fermenting for 4 days, insert Candida tropicalis an...

Embodiment 2

[0019] (1) Dilute acid pretreatment of stalks: the stalks are hydrolyzed at a temperature of 115° C. for 2 hours through 0.3% dilute sulfuric acid at a weight ratio of 1:6 of the stalks and dilute sulfuric acid, and then the hydrolyzed solution is decomposed by a screw extruder. The solid and liquid are separated to obtain dilute acid pretreated straw;

[0020] (2) Mixing the ethanol fermentation waste liquid with dilute acid pretreated straw: the straw dilute acid pretreated is mixed with a certain volume of waste water after ethanol fermentation and distillation, so that the moisture content is 70%;

[0021] (3) Solid-state fermentation: After sterilization of the dilute mixture of ethanol fermentation waste liquid and acid pretreated straw, it was inserted into Penicillium recumbens and white rot fungus, the inoculum amounts were 5% and 3%, respectively, and after 4 days of pressure pulsation solid-state fermentation, the For Candida tropicalis and Lactobacillus plantarum, ...

Embodiment 3

[0024] (1) Dilute acid pretreatment of stalks: the stalks are hydrolyzed at a temperature of 125° C. for 3 hours through 0.5% dilute sulfuric acid at a weight ratio of 1:6 of the stalks and dilute sulfuric acid, and then the hydrolyzed solution is decomposed by a screw extruder The solid and liquid are separated to obtain dilute acid pretreated straw;

[0025] (2) Butanol fermentation waste liquid is mixed with dilute acid pretreated straw: the straw dilute acid pretreated is mixed with a certain volume of straw dilute acid hydrolyzed five-carbon sugar butanol fermented and distilled waste water, so that the moisture content is 76%;

[0026] (3) Solid-state fermentation: sterilized mixture of dilute acid hydrolyzed five-carbon sugar butanol fermentation waste liquid of straw and straw pretreated by dilute acid, then inoculated with Penicillium decumbens and white rot fungus, the inoculum amounts were 3% and 4% respectively After 4 days of pressure pulsation solid-state ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com