Supported non-metallocene polyolefin catalyst, preparation method and application

A polyolefin catalyst, non-metallocene technology, applied in the field of supported non-metallocene polyolefin catalysts, can solve the problems of sticky kettle, narrow molecular weight distribution of olefin polymers, low insertion rate of comonomers, etc. Mild conditions and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

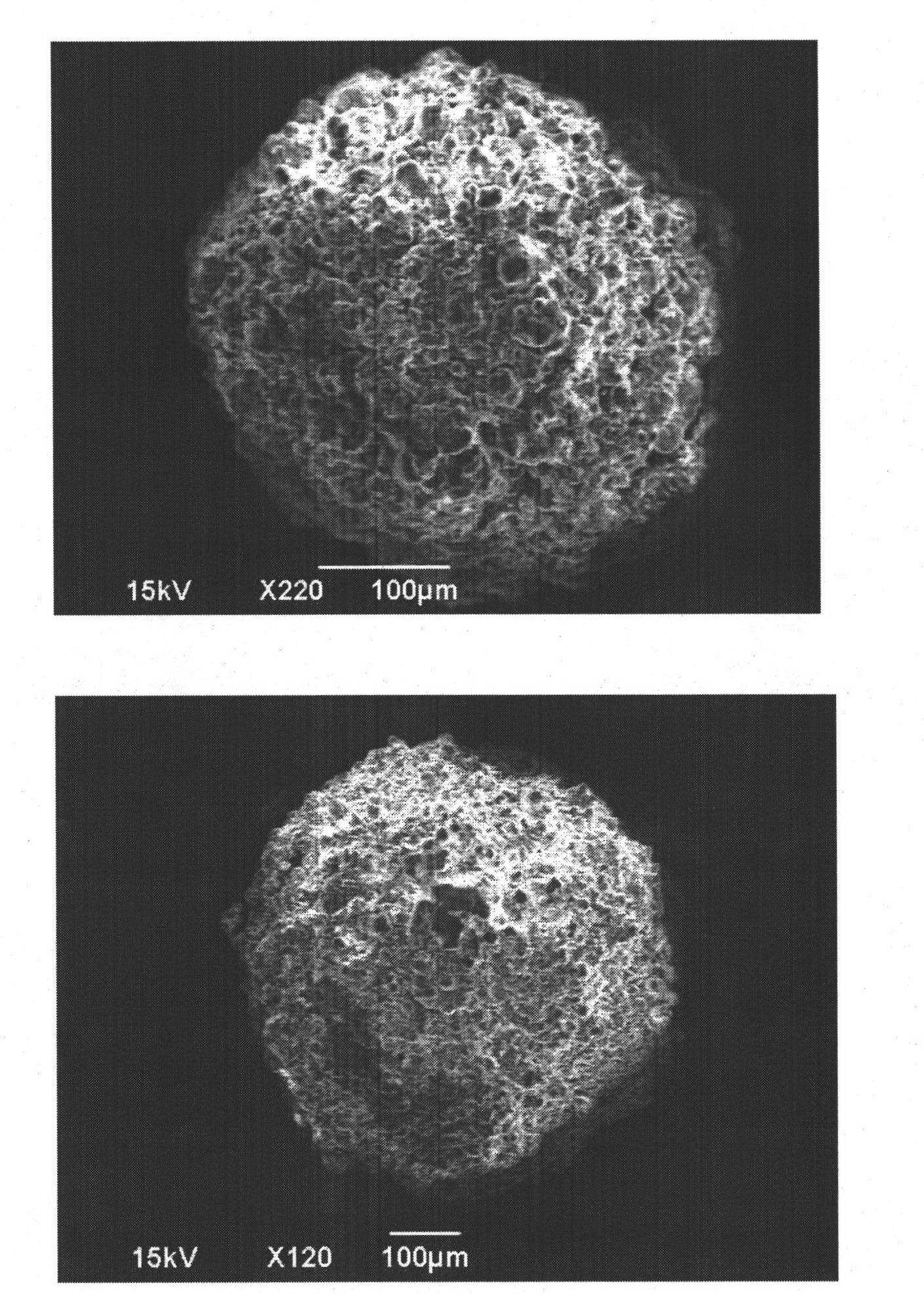

[0063] (1) Chemical treatment of magnesium compounds

[0064] Take 10.0g of spherical magnesium chloride, in which the ethanol content is 52%, the volume average particle size D[4,3] is 48um, add 50ml of hexane, slowly add 18ml of triethylaluminum in a nitrogen atmosphere, after the addition, mechanically stir (Rotation speed: 100 rpm) Continue the reaction for 2 hours, filter with suction, wash twice with 50 ml of hexane, and dry under reduced pressure to obtain activated spherical magnesium chloride, which is recorded as SMC.

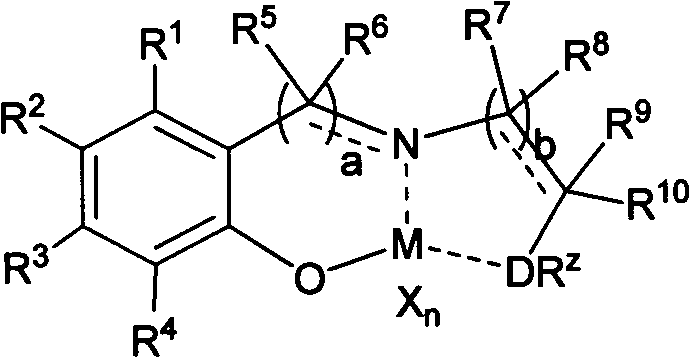

[0065] (2) Preparation of catalyst 1

[0066]

[0067] Add 0.1g of the metal complex A1 as shown in the figure above into 10ml of dichloromethane. After it is completely dissolved, add it to 1.0g of chemically activated spherical magnesium chloride SMC. Stir mechanically for 2h under nitrogen atmosphere (rotating speed 100 rpm) ), drained under reduced pressure, washed twice with 50 ml of hexane, and dried under reduced pressure to obtain a supported non-me...

Embodiment 2

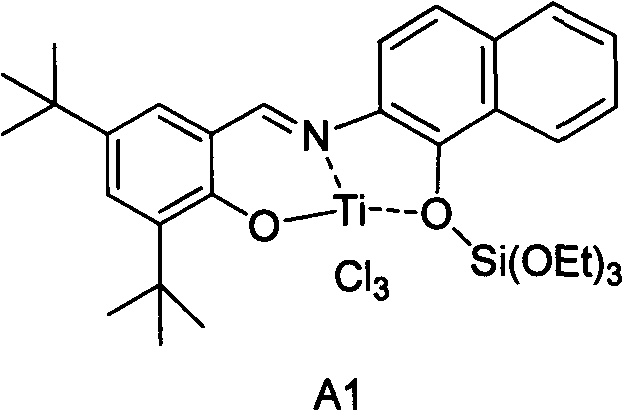

[0069] Basically the same as Example 1, the corresponding supported non-metallocene olefin polymerization catalysts C2-C10 were obtained by using the following metal complexes A2-A10, respectively.

[0070]

Embodiment 3

[0072] It is basically the same as embodiment 1, but with the following changes:

[0073] 0.15 g of non-metallocene olefin polymerization catalyst A1 was dissolved in 10 ml of methylene chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com