Preparation method of silicon and carbon composite microspheres and application thereof

A technology of silicon-carbon composites and microspheres, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of poor material uniformity, poor silicon-carbon interface contact, and poor silicon dispersion, and achieve simple and practical preparation methods High degree, the effect of improving poor circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, the preparation of silicon-carbon composite microspheres and its electrochemical performance test

[0031] Mix by chitosan (weight average molecular weight is 89000): the ratio (mass ratio) of silicon quantum dot=50:0.1, take water as solvent, stir at room temperature more than 24h, obtain the mass concentration of chitosan and silicon quantum dot The sum is a 1% solution, spray-dried, the inlet temperature is 120°C, and the outlet temperature is 110°C. The obtained microspheres were raised from room temperature to 800 °C at a rate of 10 °C / min under the protection of nitrogen, kept at a constant temperature for 6 hours, and then naturally cooled to room temperature to obtain silicon-carbon composite microspheres.

[0032] Characterization of silicon-carbon composite microspheres:

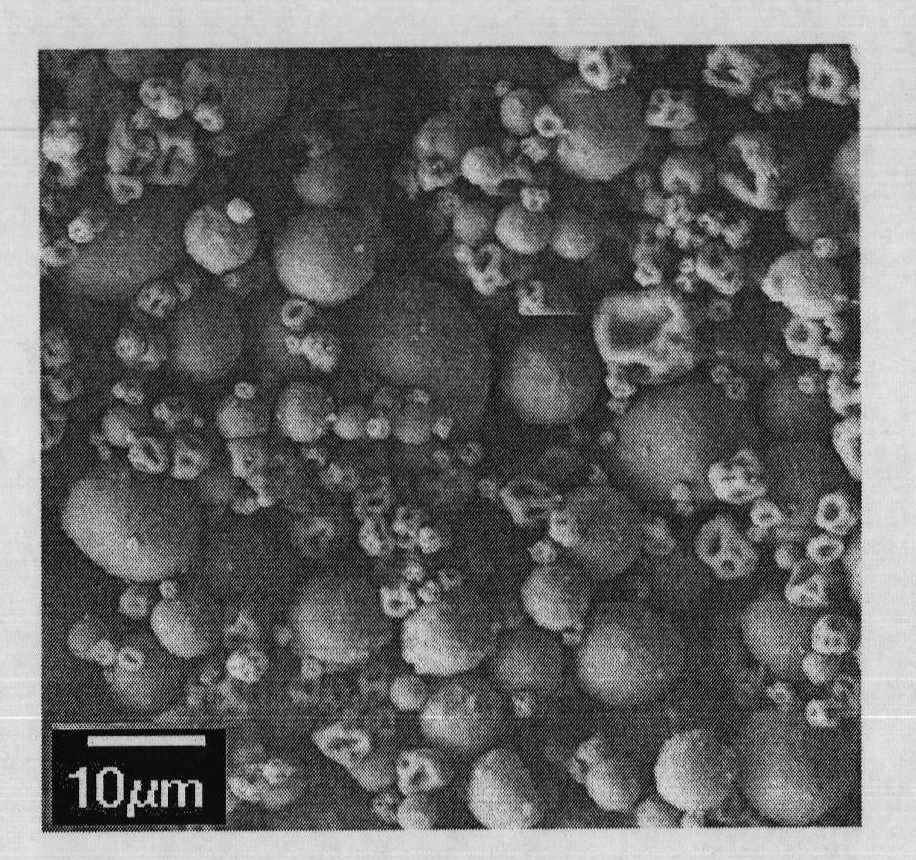

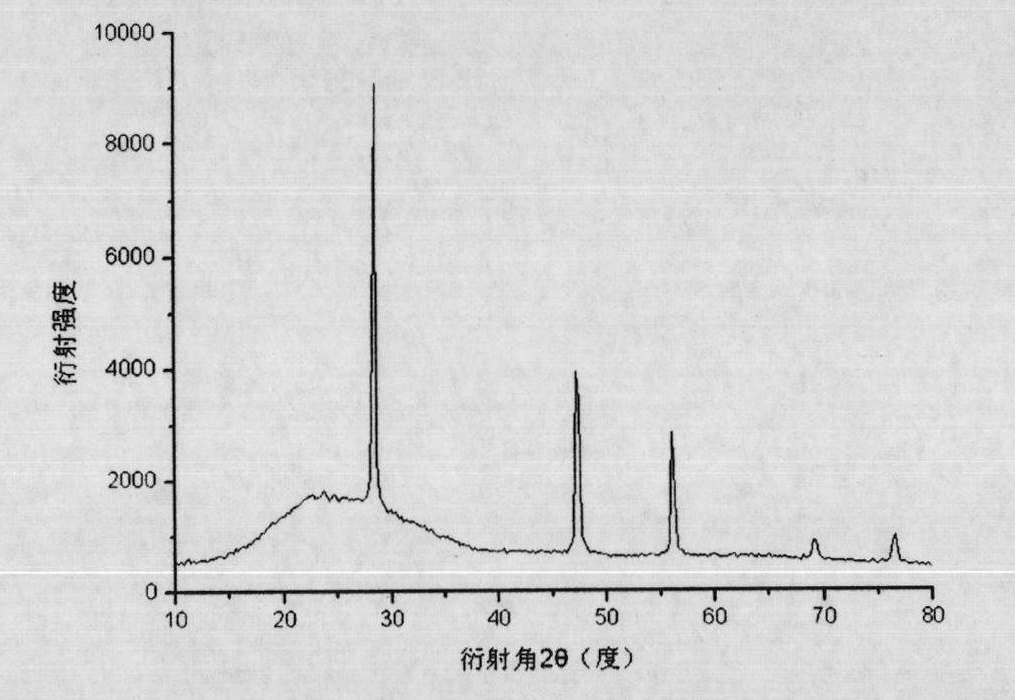

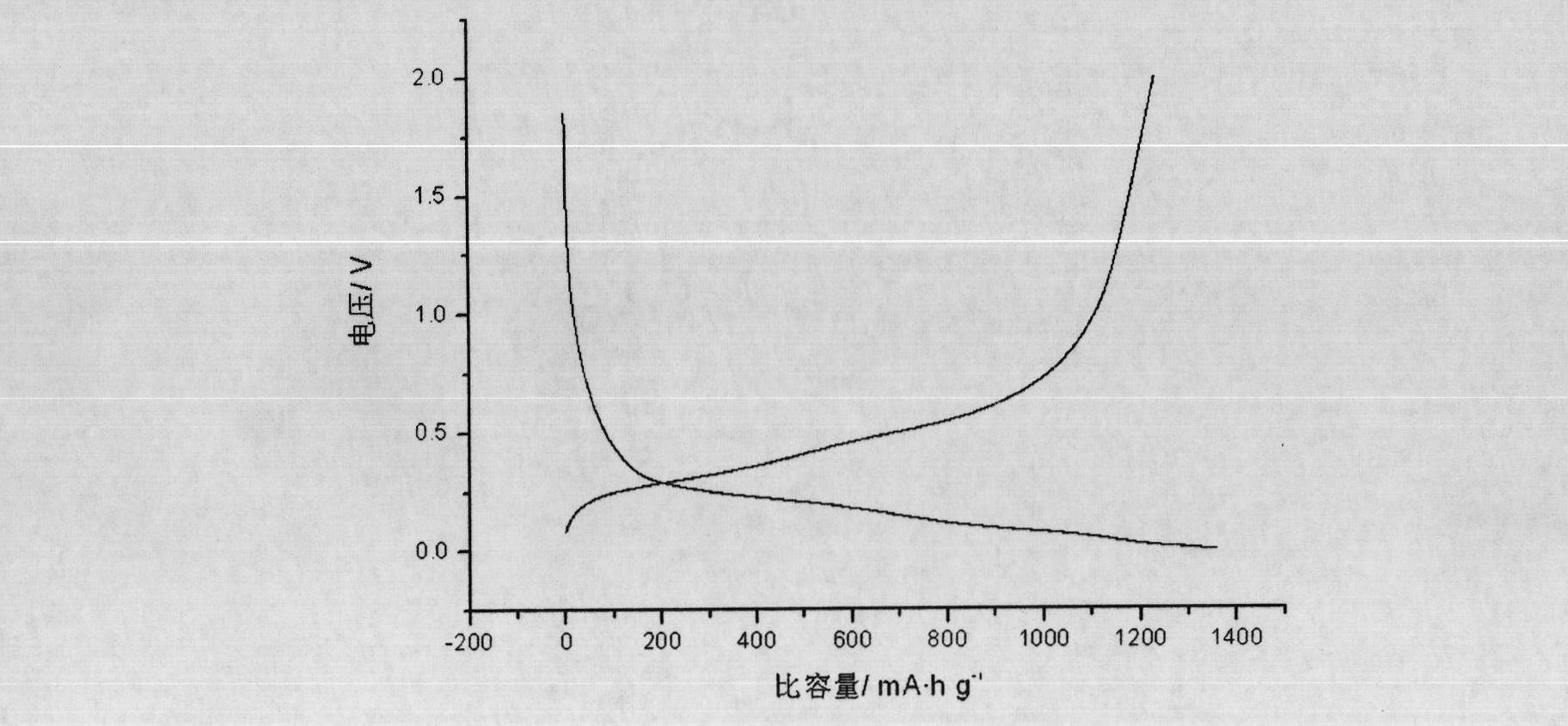

[0033] The particle size and particle size distribution of the silicon-carbon composite microspheres obtained under the above conditions were detected by a Japanese electron s...

Embodiment 2

[0038] Example 2, Preparation of Silicon Carbon Composite Microspheres and Testing of Their Electrochemical Properties

[0039] Mix by the ratio (mass ratio) of chitosan (weight-average molecular weight is 89000): silicon powder=20: 0.1, take water as solvent, stir at room temperature more than 24h, obtain the mass concentration sum of chitosan and silicon powder as a 5% solution. The polymer solution was spray-dried with an inlet temperature of 150°C and an outlet temperature of 120°C. The obtained microspheres were heated from room temperature to 300 °C at a rate of 15 °C / min) under the protection of nitrogen, and then cooled to room temperature at a rate of 10 °C / min for 6 hours to obtain silicon-carbon composite microspheres.

[0040] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1. The composition of the obtained silicon-carbon composite microspheres and the test results in the simulated bat...

Embodiment 3

[0041] Example 3, Preparation of Silicon Carbon Composite Microspheres and Testing of Their Electrochemical Properties

[0042] Mix by sodium carboxymethyl cellulose (weight average molecular weight is 250000): the ratio (mass ratio) of silicon monoxide=1: 0.1, take water as solvent, stir at room temperature more than 24h, obtain sodium carboxymethyl cellulose and The sum of the mass concentrations of silicon monoxide is 50% solution. The polymer solution was spray dried with an inlet temperature of 180°C and an outlet temperature of 105°C. The obtained microspheres were raised from room temperature to 1000 °C at a rate of 20 °C / min under nitrogen protection, and then cooled to room temperature at a rate of 10 °C / min after constant temperature for 6 hours to obtain silicon-carbon composite microspheres.

[0043] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1. The composition of the obtained si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com