Preparation method of quinine hydrochloride

A technology of quinine hydrochloride and quinine sulfate, which is applied in the fields of separation and purification and derivative preparation, can solve the problems that it is not easy and difficult to obtain quinine hydrochloride crystallization, precipitation and filtration is cumbersome, and achieves low cost and is beneficial to scaled production and preparation. The effect of simple and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of quinine: quinine sulfate and water are mixed in a mass ratio of 1: 40, then the pH value of the aforementioned solution is adjusted to 4 with dilute hydrochloric acid of 1mol / L, so that quinine sulfate is dissolved; then heated to 60 ℃, under the condition of stirring, adjust the pH value of the solution to 10 with a mass percentage of 5% sodium hydroxide solution, and then stir for at least 1 hour. After the stirring is completed, cool down, filter out the precipitate quinine, and wash the precipitate with water until it is washed out The pH value of the aqueous solution was 7, and the quinine was dried at 60° C. for 4 hours after filtering to obtain quinine.

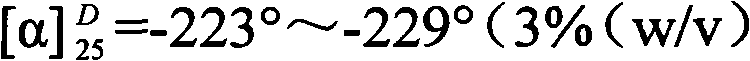

[0032] (2) Preparation of quinine hydrochloride: Weigh 3.24g of quinine in a 100mL round bottom flask, add 22mL of methanol and stir to dissolve at room temperature, slowly add about 0.91mL of concentrated hydrochloric acid with a concentration of 36% by mass percentage, under airtight conditio...

Embodiment 2

[0035] (1) Preparation of quinine: quinine sulfate and water are mixed in a mass ratio of 1: 45, then the pH value of the aforementioned solution is adjusted to 4 with 1mol / L dilute hydrochloric acid, so that quinine sulfate is dissolved; then heated to 60 ℃, under the condition of stirring, adjust the pH value of the solution to 10 with a mass percentage of 5% sodium hydroxide solution, and then stir for at least 1 hour. After the stirring is completed, cool, filter out the precipitate quinine, and wash the precipitate with water to the pH value It was 8, and the precipitated quinine was filtered and dried at 65°C for 4 hours to obtain quinine.

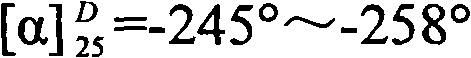

[0036] (2) Preparation of quinine hydrochloride: Weigh 3.24g of quinine in a 100mL round bottom flask, add 18mL of ethanol alcohol and stir to dissolve at room temperature, slowly add about 0.91mL of concentrated hydrochloric acid with a mass percentage concentration of 36%, and keep the The reaction was stirred for 25 min. Concentr...

Embodiment 3

[0039] (1) Preparation of quinine: quinine sulfate and water are mixed in a mass ratio of 1:50, then the pH value of the aforementioned solution is adjusted to 4 with dilute hydrochloric acid of 1mol / L, so that quinine sulfate is dissolved; then heated to 60 ℃, under the condition of stirring, adjust the pH value of the solution to 10 with a mass percentage of 5% sodium hydroxide solution, and then stir for at least 1 hour. After the stirring is completed, cool down, filter out the precipitate quinine, wash the precipitate with water until it is filtered out The pH value of the aqueous solution is 7.5, and the precipitated quinine is filtered out and dried at 70° C. for 3 hours to obtain quinine.

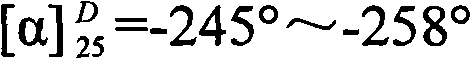

[0040] (2) Preparation of quinine hydrochloride: Weigh 3.24g of quinine in a 100mL round bottom flask, add 24mL of 1-propanol and stir to dissolve at room temperature, slowly add about 0.9mL of concentrated hydrochloric acid with a mass percentage concentration of 36%, and seal the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com