Method for measuring edible oleic acid value based on conductivity

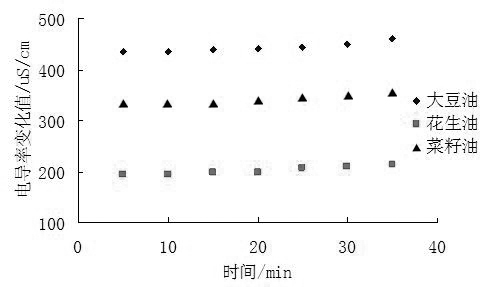

A technology of edible oil and electrical conductivity, which is applied in the field of chemical analysis and detection, can solve the problems of high dependence, low measurement accuracy, and large amount of oil samples, and achieve the effect of reducing test errors, simple instrument requirements, and small usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Embodiment 1: Determination of acid value of rapeseed oil (with vitamin E added)

[0081] 1) Rapeseed oil (with vitamin E added) is commercially available and sampled evenly.

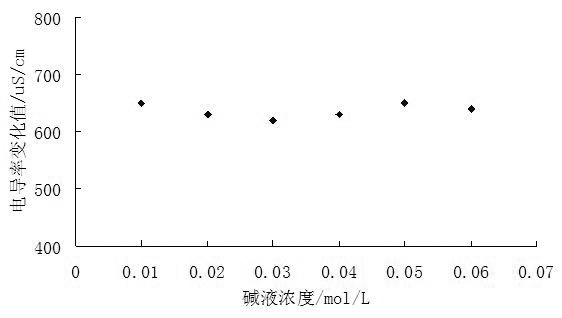

[0082] 2) Model establishment: prepare a KOH solution with a concentration of about 0.06mol / L and measure its conductivity. Take 5g of 10 liquid edible oil samples with known acid value, accurate to 0.001g. Put the oil sample to be tested in a 50mL Erlenmeyer flask, control the mixing ratio of oil and alkali to 1:3 (w / v), that is, add 15mL of KOH solution, shake for 5s, let it stand for 3min, and directly insert the electrode through the oil layer into the lye layer, and measure the change in conductivity of the extract. Establish the functional relationship between the acid value of edible oil and the change value of conductivity: y=0.0007x+0.1096 (y-the acid value of the sample to be tested, x-the change value of the conductivity of the KOH aqueous phase of the sample to be tested, the same...

Embodiment 2

[0089] Embodiment 2: Determination of acid value of market frying oil

[0090] 1) The frying oil was collected from a restaurant in Yangling District, Shaanxi, and evenly sampled after filtration.

[0091] 2) Model establishment: prepare a KOH solution with a concentration of 0.05mol / L and measure its conductivity. Take 5g of 10 liquid edible oil samples with known acid value, accurate to 0.001g. Put the oil sample to be tested in a 50mL Erlenmeyer flask, control the mixing ratio of oil and alkali to 1:5 (w / v), that is, add 25mL of KOH solution, shake for 5s, let it stand for 3min, and directly insert the electrode through the oil layer into the lye layer, and measure the conductivity change of the lye layer. Establish the functional relationship between the acid value of edible oil and the change value of electrical conductivity: y=0.001x+0.017.

[0092] 3) Model verification: take edible oil with known acid value and different from the type of modeling oil sample, confi...

Embodiment 3

[0098] Embodiment 3: the determination of the acid value of market chafing dish oil

[0099] 1) Hot pot oil was collected from a hot pot restaurant in Yangling District, Shaanxi Province, and evenly sampled after filtration and decolorization.

[0100] 2) Model establishment: KOH solution with a concentration of 0.04mol / L was prepared and its conductivity was measured. Take 5g of 10 liquid edible oil samples with known acid value, accurate to 0.001g, and heat the solid to liquid. Put the oil sample to be tested in a 50mL Erlenmeyer flask, control the mixing ratio of oil and alkali to 1:10 (w / v), that is, add 50mL of KOH solution, shake for 5s, let it stand for 3min, and directly insert the electrode through the oil layer into the water phase , to measure the change in the conductivity of the extract. Establish the functional relationship between the acid value of edible oil and the change value of electrical conductivity: y=0.0024x-0.01571.

[0101] 3) Model verification:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com