Method for preparing quasi three-dimensional photonic crystals on potassium titanyl oxygenic phosphate crystals

A technology of potassium titanyl phosphate and photonic crystal, which is applied in the direction of light guide, optics, optical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

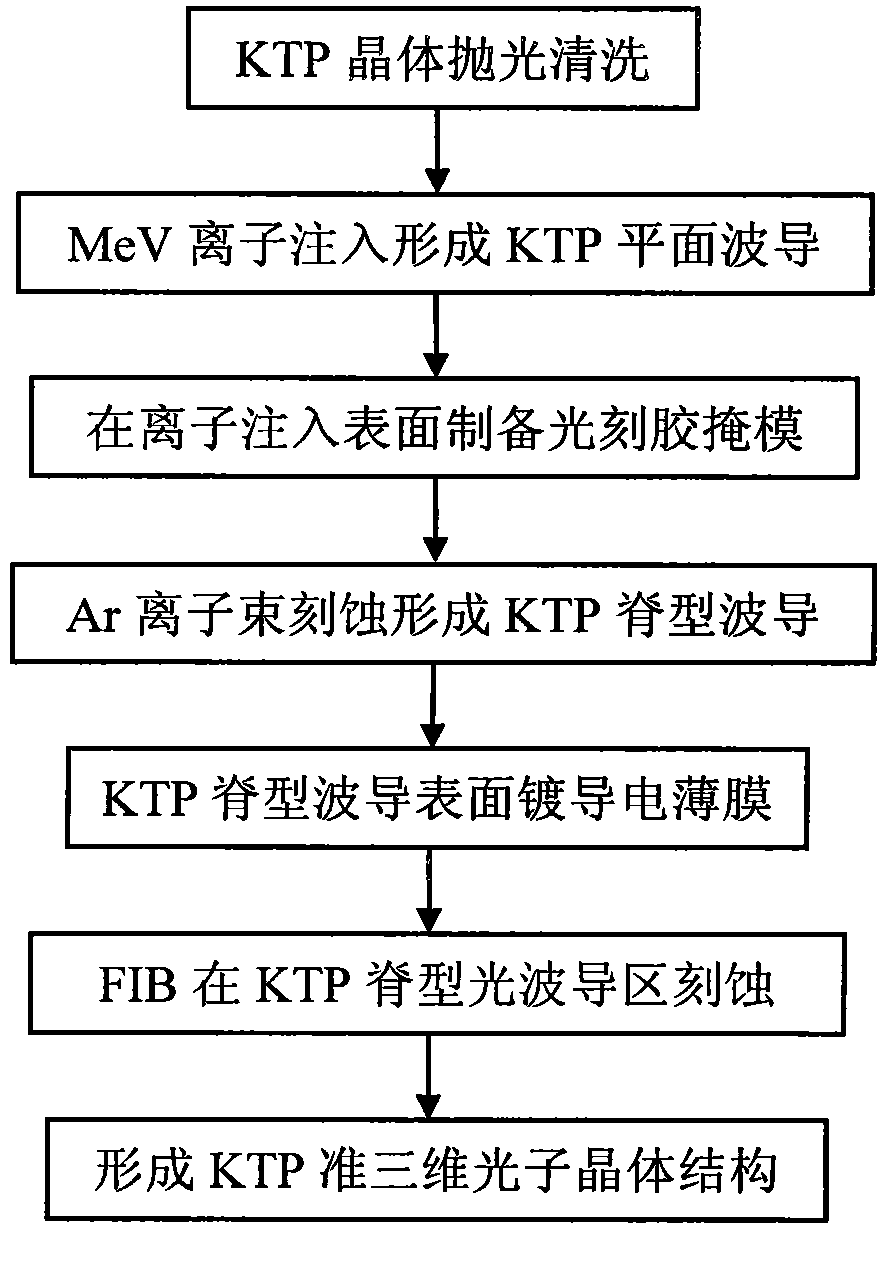

[0021] A method for preparing a quasi-three-dimensional photonic crystal structure on a potassium titanyl phosphate crystal, the method is:

[0022] 1) Prepare and process the sample: the sample is a Z-cut KTP crystal with a size of 10mm×10mm and a thickness of 2mm; the surface of the sample and the two opposite end faces are optically polished, and then cleaned with deionized water, alcohol and acetone;

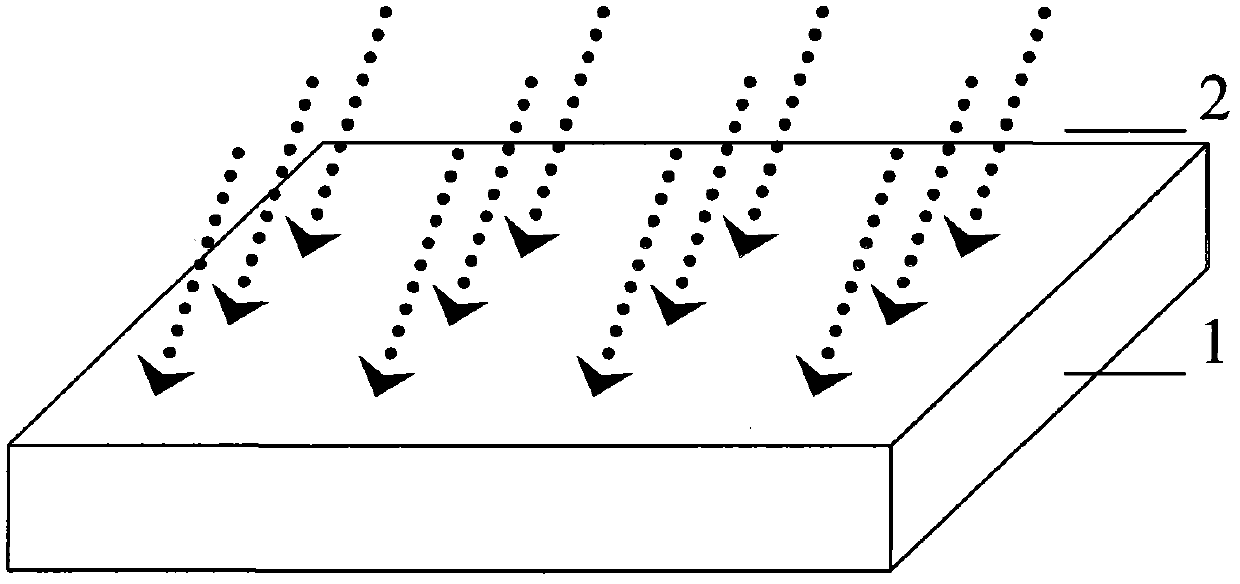

[0023] 2) Ion implantation to form a planar waveguide structure: put the cleaned KTP sample into the accelerator target chamber for light ion or heavy ion implantation, the implantation conditions are: light ion H + , energy: 400keV; heavy ion C + , energy: 1MeV; dose is light ion 5×10 16 Ions / cm², heavy ions 1×10 13 Ions / cm2; beam current is 20nA;

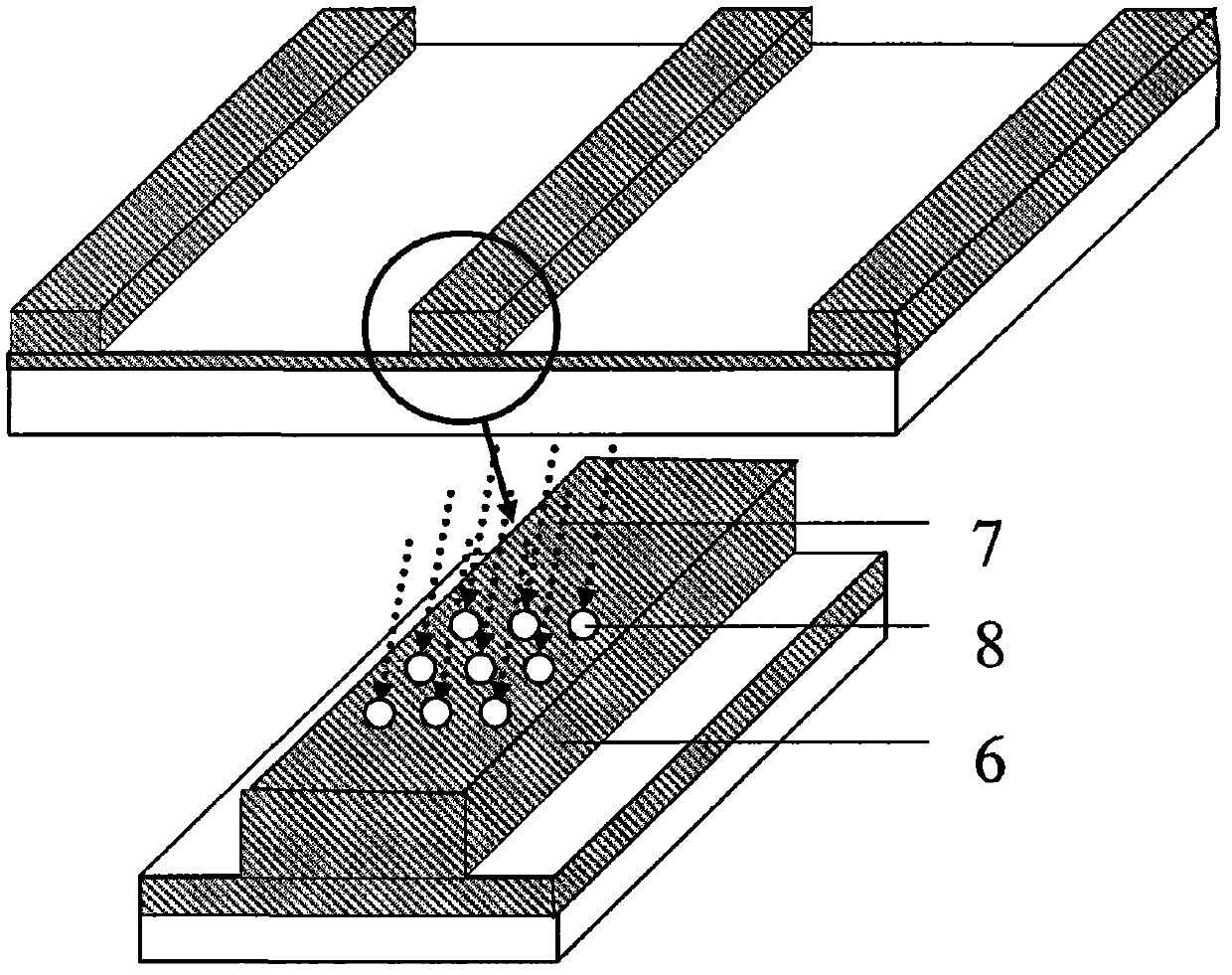

[0024] 3) Prepare a photoresist mask on the planar waveguide structure: Spin and coat BP218 photoresist on the planar waveguide structure with a homogenizer. Expose a 5 micron mask, then develop it with a positive photoresis...

Embodiment 2

[0029] A method for preparing a quasi-three-dimensional photonic crystal structure on a potassium titanyl phosphate crystal, the method is the same as in Example 1, the difference is that in step 2), the implantation condition is: light ion He + , energy: 500keV; heavy ion O + , energy: 1.5MeV; in step 3), the mask plate exposure with a shading stripe spacing of 30 microns and a shading stripe width of 10 microns; in step 4), the Ar ion beam energy is 1.5KeV, and the beam current density is 30 milliamperes / cm, etch to form a KTP ridge waveguide with a width of 10 microns and a depth of 0.8 microns; in step 6), the hole pitch of the quasi-three-dimensional photonic crystal is 600 nm, and the hole radius is 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com