Method for manufacturing double diffusion type optical avalanche diode with incident light on back surface by adopting epitaxial equipment

A double diffusion, avalanche tube technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of PN junction interface depression, inability to achieve doping, slow diffusion rate, etc., to reduce series resistance, suppress surface electric field, avoid absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

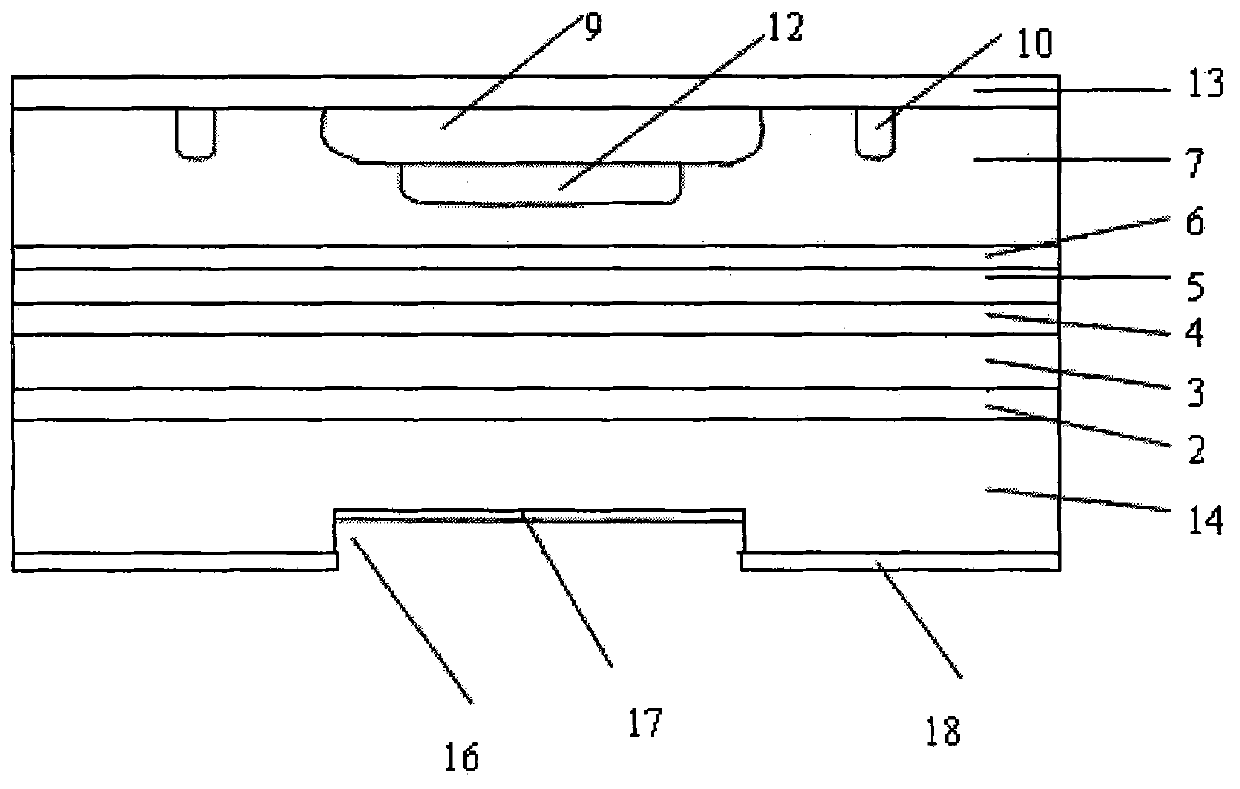

[0031] The invention adopts MOCVD epitaxy equipment to carry out primary epitaxy of avalanche photodiode on indium phosphide substrate, adopts MOCVD epitaxy equipment double-diffusion mode diffusion method to do doping and sputter P surface electrode, substrate is thinned, and light entrance hole on the back Wet etching, growing anti-reflection layer, making N-side electrode and electrode alloying.

[0032] The present invention will be described in detail below with reference to the accompanying drawings.

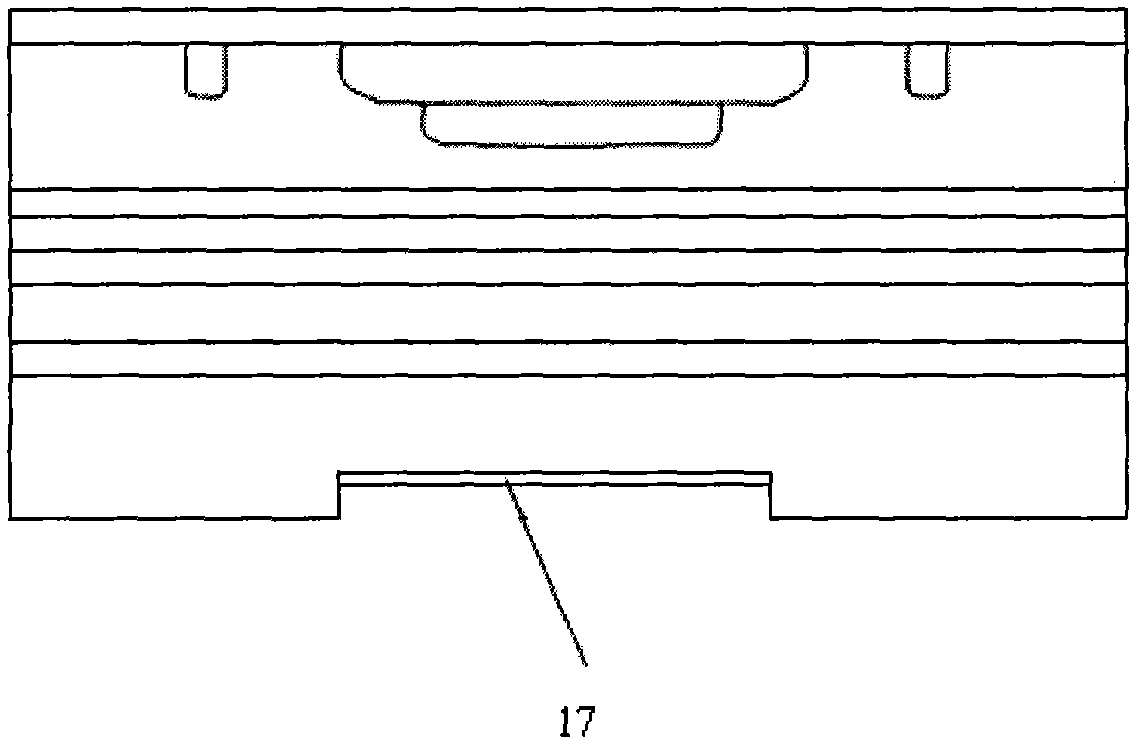

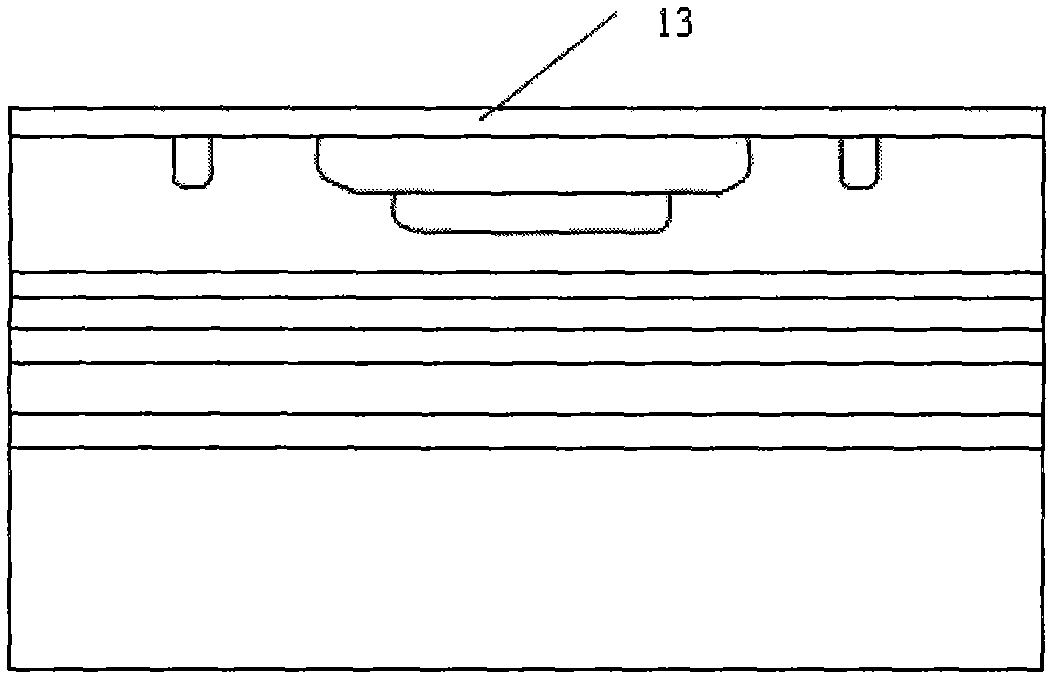

[0033] The primary epitaxy of the avalanche photodiode is carried out on the indium phosphide substrate by MOCVD, and the epitaxy is composed of seven layers (see figure 1 ), from bottom to top are S-doped N-type indium phosphide substrate 1, 1 micron N-type indium phosphide buffer layer 2, 2 micron doping concentration of i-type indium gallium arsenic absorber layer of 1E15cm^(-3) 3. 0.2 micron N-type indium phosphide layer 4, 0.12 micron InGaAsP gradient layer 5, 0.4 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com