Method and device for preparing high-purity boron tribromide

A boron tribromide, high-purity technology, applied in the direction of boron halide compounds, etc., can solve the problems of low purity of synthetic products, affecting the performance of high-purity boron bromide, etc., and achieve the effect of less impurities, simple equipment and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

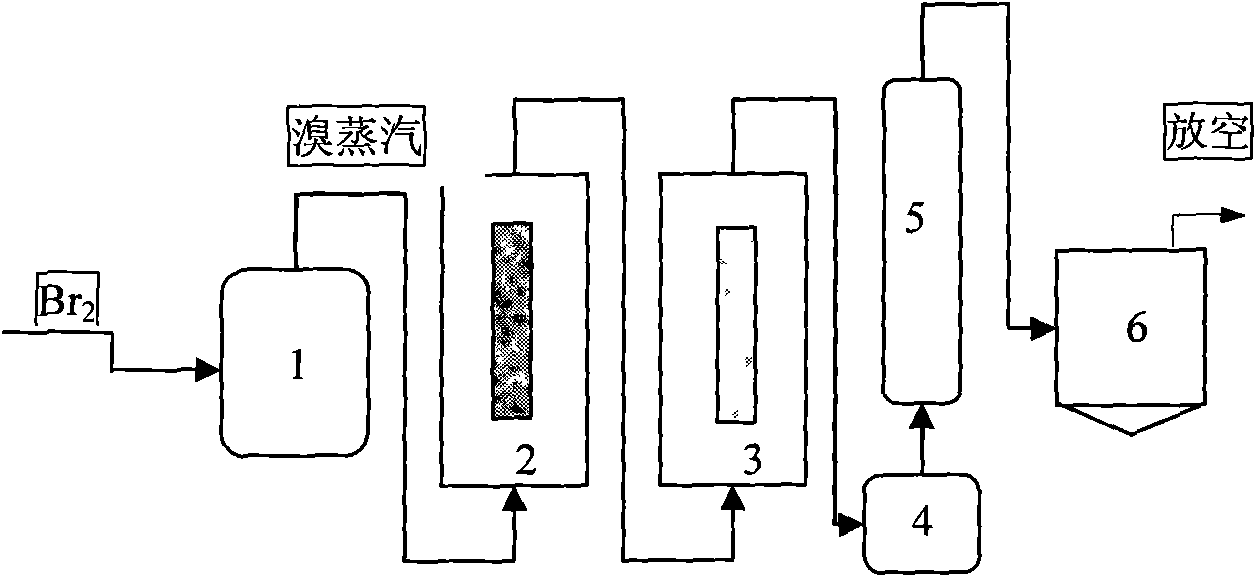

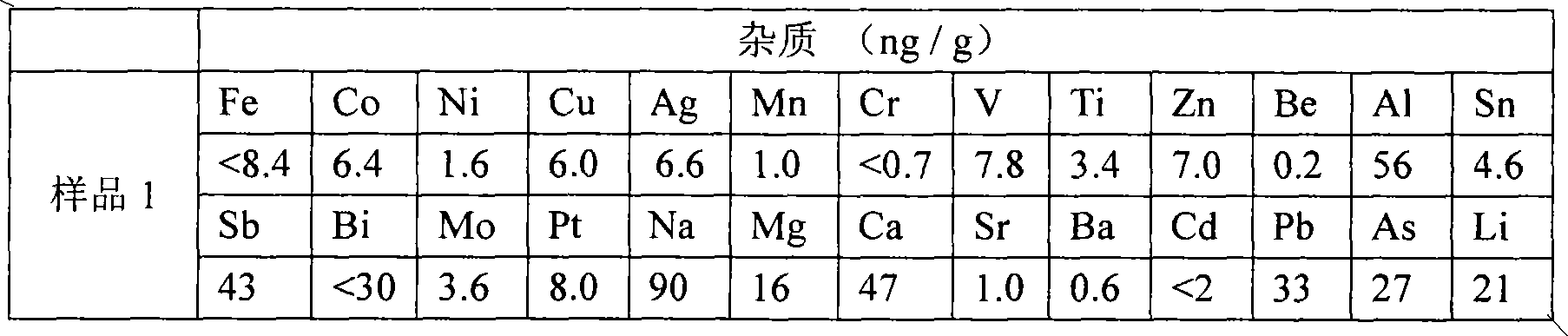

[0036]500g of industrial boron powder (80%-98%) was washed with 5L0.3mol / L hydrochloric acid to make a boron block and put it into a bromination furnace. After the temperature rose to 600°C, 5kg of liquid bromine (> 99.5%) enters the bromination furnace 2 through the pipeline from the bottom after being vaporized by the vaporizer 1, and the gasification temperature is 45° C. to obtain red fuming gas. , react with the 5N high-purity aluminum sheet in the furnace at a temperature of 50°C to obtain white boron bromide gas, the resulting gas is water-cooled to form a white liquid that flows into the collector 4, and the temperature of the collector 4 is controlled so that boron bromide passes through the outlet of the collector. The pipeline enters the fractionation column 5 for fractionation, and the low-boiling point impurities evaporate before boron bromide, while the high-boiling point impurities remain in the collector 4, and the fraction at 102-105°C is selected, which is the...

Embodiment 2

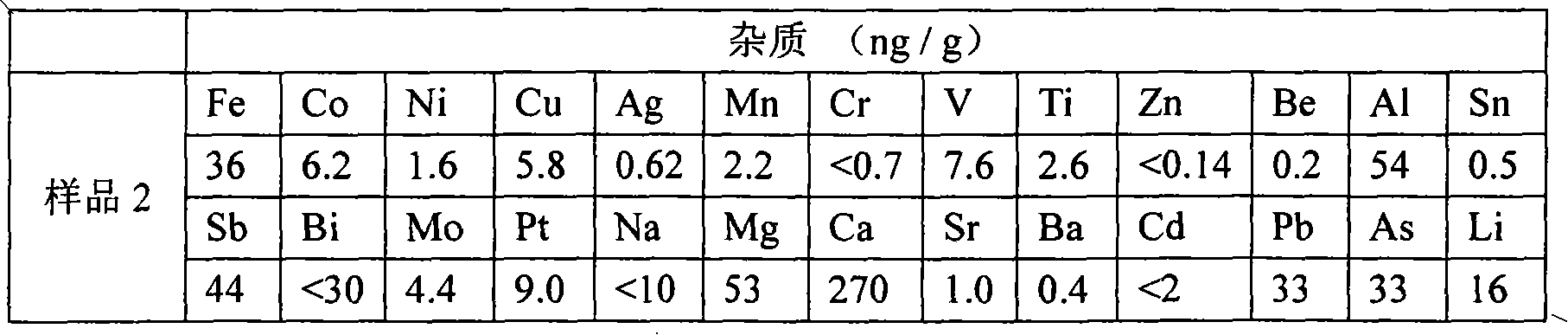

[0040] 500g industrial boron powder (80%-98%) is made into boron block after being washed with 3L1mol / L sulfuric acid and is packed in the bromination furnace 2. After the temperature rises to 850°C, 5kg liquid bromine (>99.5 %) enters the bromination furnace 2 through the pipeline from the bottom after being gasified by the vaporizer 1, and the gasification temperature is 50° C. to obtain red fuming gas. React with 4N high-purity aluminum flakes in the furnace at a temperature of 150°C to obtain white boron bromide gas. The resulting gas is water-cooled to form a white liquid and flows into collector 4. Control the temperature of collector 4 so that boron bromide passes through the pipe from the outlet of the collector. After entering the fractionation column 5 for fractionation, the low-boiling point impurities evaporate before the boron bromide, and the high-boiling point impurities remain in the collector 4, and the fraction at 95-98°C is selected, which is the evaporation ...

Embodiment 3

[0044] 500g industrial boron powder (80%-98%) is made into boron block after being washed with 2L2mol / L nitric acid and is packed in the bromination furnace 2. After the temperature rises to 770° C., 5 kg of liquid bromine (>99.5 %) enters the bromination furnace 2 through the pipeline from the bottom after being gasified by the vaporizer 1, and the gasification temperature is 60° C. to obtain red fuming gas. React with 6N high-purity aluminum flakes in the furnace at a temperature of 100°C to obtain white boron bromide gas. The resulting gas is water-cooled to form a white liquid and flows into collector 4. Control the temperature of collector 4 so that boron bromide passes through the pipeline from the outlet of the collector After entering the fractionation column 5 for fractionation, the low-boiling point impurities evaporate before the boron bromide, and the high-boiling point impurities remain in the collector 4, and the fraction at 117-120°C is selected, which is the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com