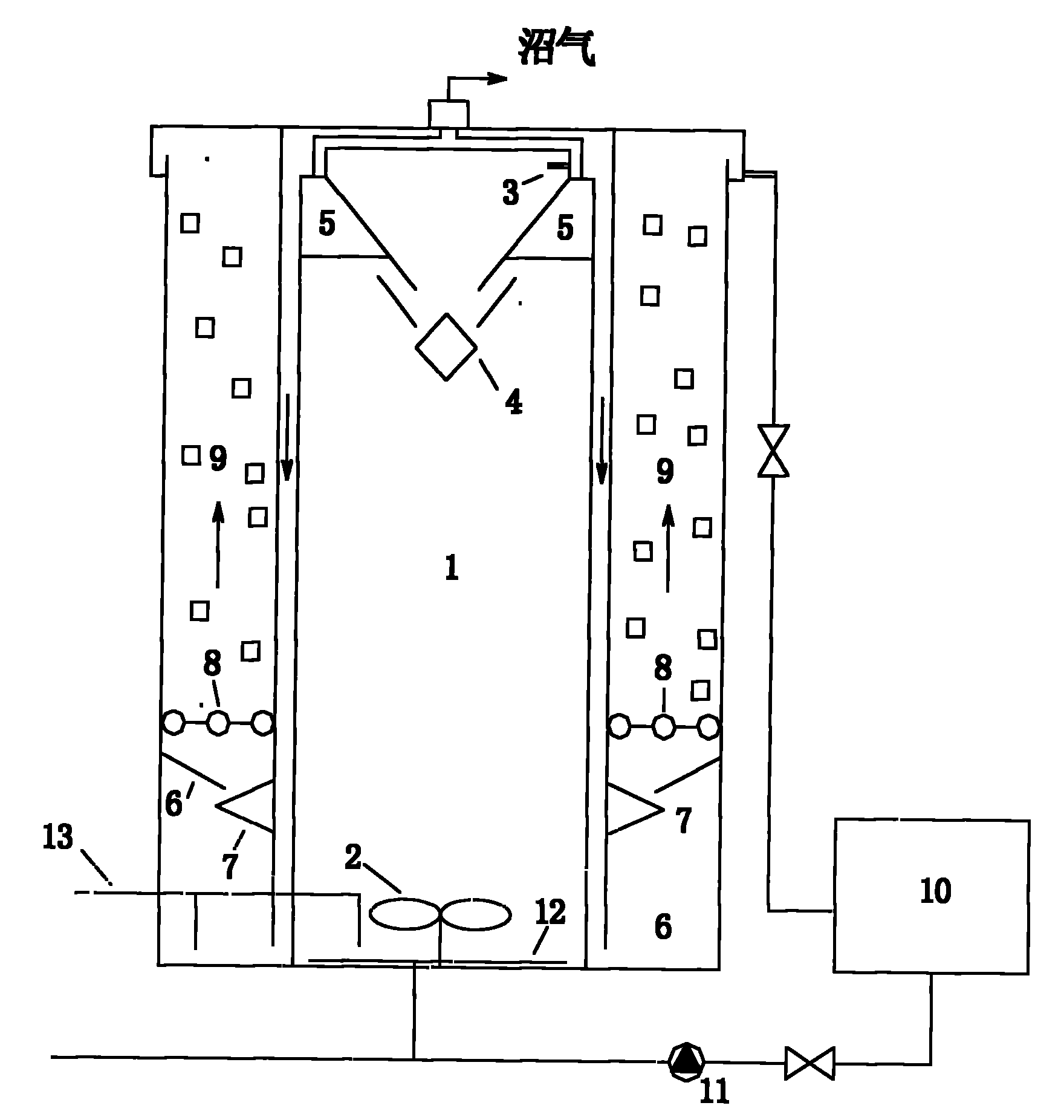

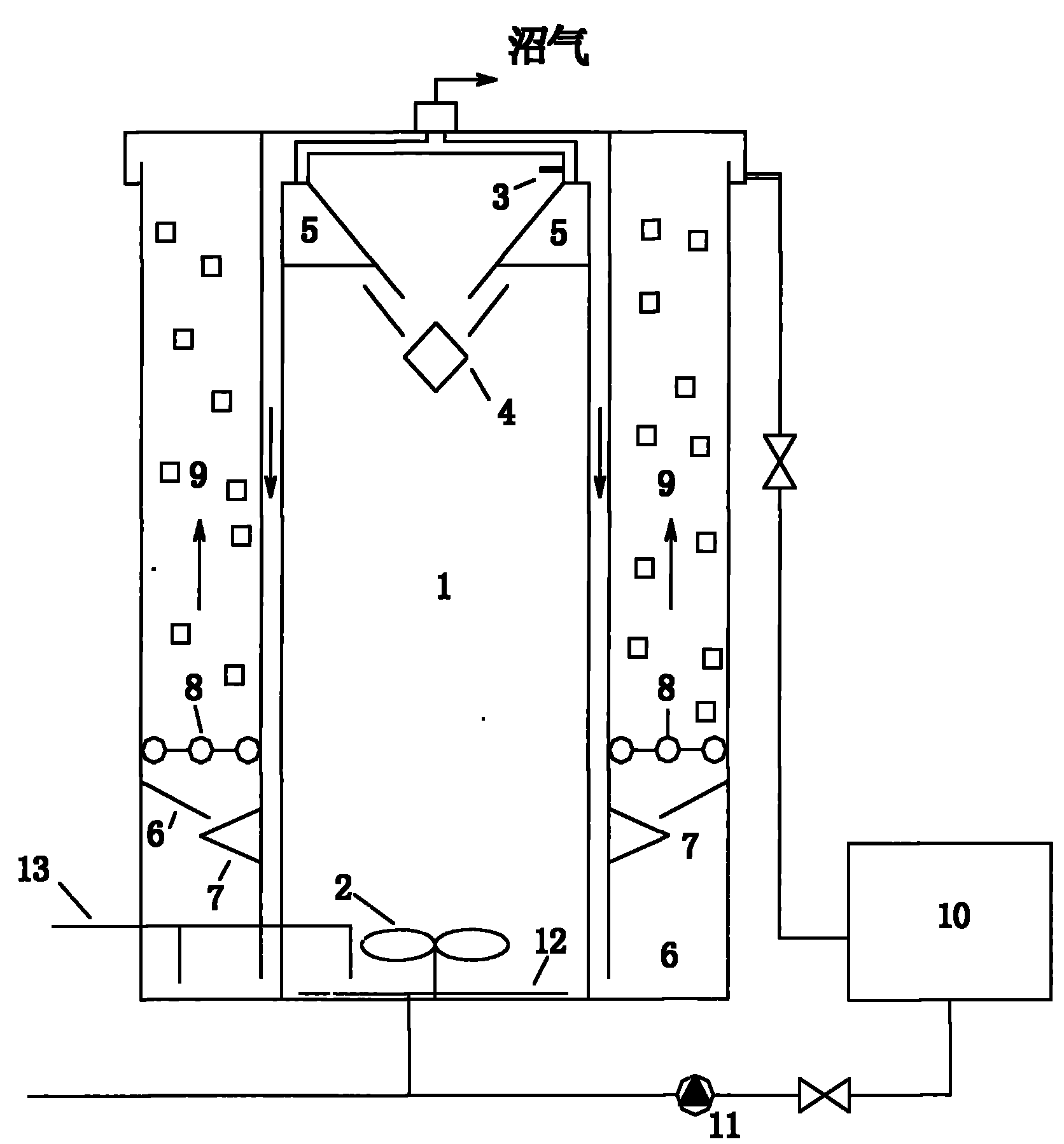

Integrated bioreactor as well as application thereof and method for treating high-concentration organic wastewater

A bioreactor and organic wastewater technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as easy acidification, and achieve the effect of low cost, easy maintenance, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Its equipment and treatment process are the same as above, and the high-concentration organic wastewater is treated in winter with the present invention, the temperature is 5~15°C, and the wastewater quality is shown in Table 1:

[0034] Table 1 Water quality indicators of high-concentration organic wastewater

[0035] water quality index

COD (mg / L)

BOD(mg / L)

pH

variation range

3500~4500

2900~3600

6.5~8.5

400~750

[0036] The hydraulic retention time of UASB is 18h, and the hydraulic retention time of MBBR is 6h. Suspended filler with a specific gravity of 0.96 is added to the MBBR area, the filling rate is 60%, and the dissolved oxygen content is 4mg / L. During operation, strictly monitor the pH of the effluent from the UASB reactor, and adjust the reflux ratio in time. The lowest pH is 6.3. At this time, adjusting the reflux ratio to 300% can restore the pH to above 6.8. During operation, the t...

Embodiment 2

[0041] Its equipment and processing flow are the same as above, handle certain brewery wastewater in winter with the present invention, and the wastewater quality is shown in Table 3:

[0042] Table 3 High-concentration organic wastewater water quality indicators

[0043] water quality index

COD (mg / L)

BOD(mg / L)

pH

variation range

1800~2600

900~1600

6.0~7.0

300~550

[0044] The hydraulic retention time of UASB is 14h, and the hydraulic retention time of MBBR is 4h. Suspended filler with a specific gravity of 0.99 is added to the MBBR area, the filling rate is 40%, and the dissolved oxygen content is 2mg / L. During operation, strictly monitor the pH of the effluent from the UASB reactor, and adjust the reflux ratio in time. The lowest pH is 6.5. At this time, adjusting the reflux ratio to 200% can restore the pH to above 6.8. During operation, the treatment effect of the integrated reactor is good and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com