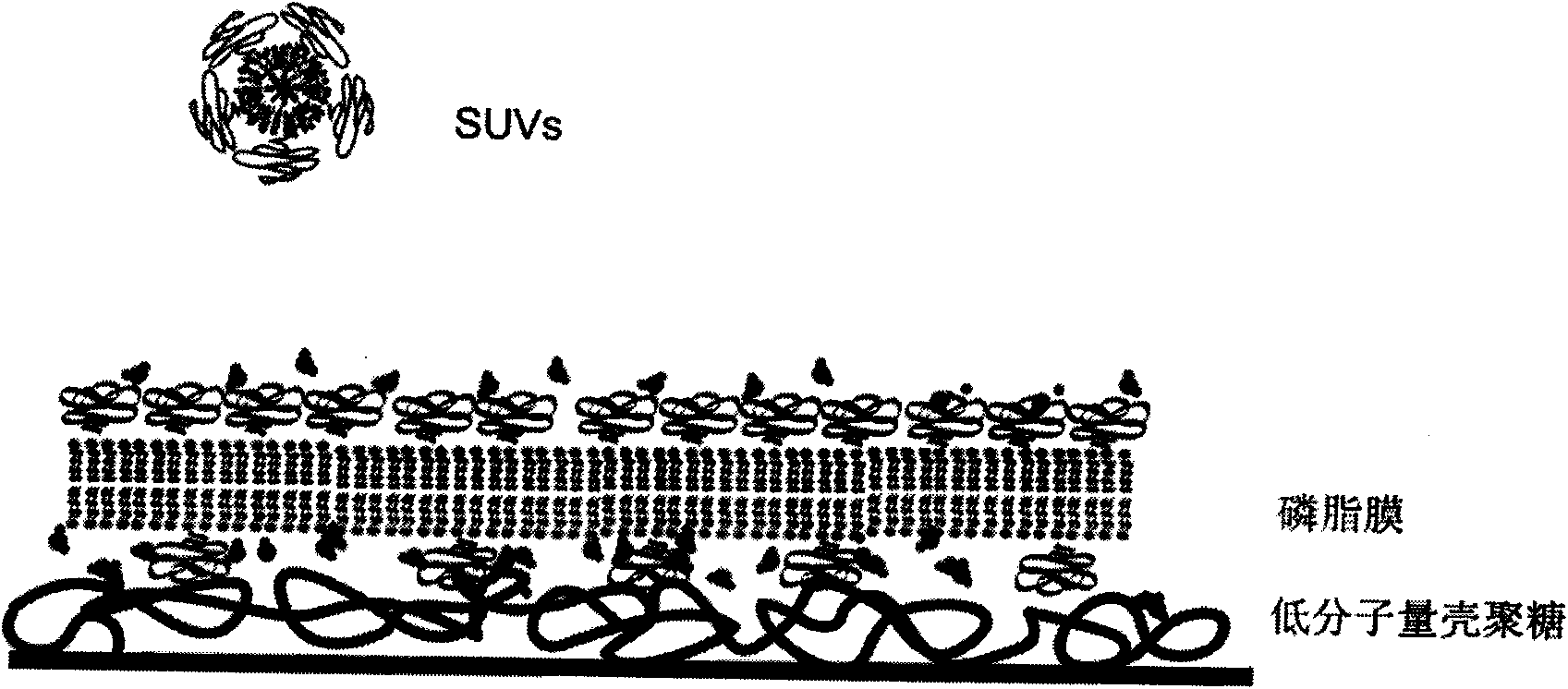

Method for modifying air stability phospholipid membrane on solid surface

An air-stable, solid surface technology, applied in the field of surface chemistry and applied chemistry, can solve the problem of inability to modify air-stable phospholipid membranes, and achieve the effects of good air stability, shortened preparation time, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare a chloroform solution of 1,2-dimyristoylphosphatidylcholine (1,2-Dimyristoylphophatidylcholine, DMPC), which contains 1,2-distearoyl-glycerol-3-phosphatidylethanolamine-N-carboxyl (polyethylene Diol 2000) (1,2-Distearoyl-sn-Glycero-3-Phosphoethanolamine-N-[Methoxy(Polyethyleneglycol)-2000], DSPE-PEG2000) were 0.1, 0.5, 1.5 mol%, respectively. Blow dry most of the chloroform with nitrogen, then vacuum dry for at least 2 hours to remove residual chloroform and form a phospholipid film on the container wall; add a certain amount of phosphate buffer (pH 7.4) to hydrate the film and make it The final concentration of DMPC was 1 mM. Ultrasonic treatment in a water bath for 30-60 min until the solution was clear; then the solution was extruded with Avanti's MiniExtruder, using a polycarbonate membrane with a pore size of 50 nm, and the number of extrusions was not less than 11.

[0029] Carry out amination modification on the surface of silicon wafers by conventional ...

Embodiment 2

[0033] Prepare a chloroform solution of 1,2-dioleoylphosphatidylcholine (Dioleoylphatidylcholine, DOPC), which contains 1mol% of DSPE-PEG 2000 First, dry most of the chloroform with nitrogen, and then vacuum-dry for at least 2 hours to remove residual chloroform and form a phospholipid film on the container wall; add a certain amount of phosphate buffer (pH 7.4) to hydrate the film, and The final concentration of DOPC was 1 mM. Ultrasonic treatment in a water bath for 30-60 min until the solution was clear; then the solution was extruded with Avanti's MiniExtruder, using a polycarbonate membrane with a pore size of 50 nm, and the number of extrusions was not less than 11.

[0034] The preparation steps of the "chitosan-modified glass surface" are the same as in Example 1.

[0035] The above-prepared small single-walled phospholipid vesicles and the chitosan-modified glass surface are allowed to stand for a reaction, and after 5-10 minutes at room temperature, the unbound exce...

Embodiment 3

[0037] Preparation of 1,2-dilauroylphosphatidylethanolamine (1,2-Dilauroyl-sn-Glycero-3-Phosphoethanolamine, DLPE) in chloroform, containing 2mol% of DSPE-PEG 2000 First, dry most of the chloroform with nitrogen, and then vacuum-dry for at least 2 hours to remove residual chloroform and form a phospholipid film on the container wall; add a certain amount of phosphate buffer (pH 7.4) to hydrate the film, and The final concentration of DLPE was 1 mM. Ultrasonic treatment in a water bath for 30-60 min until the solution was clear; then the solution was extruded with Avanti's MiniExtruder, using a polycarbonate membrane with a pore size of 50 nm, and the number of extrusions was not less than 11.

[0038] The preparation steps of the "chitosan-modified silica surface" are the same as in Example 1.

[0039] The above-prepared small single-walled phospholipid vesicles and the chitosan-modified silicon dioxide surface are allowed to stand for a reaction, and after 5-10 minutes at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com