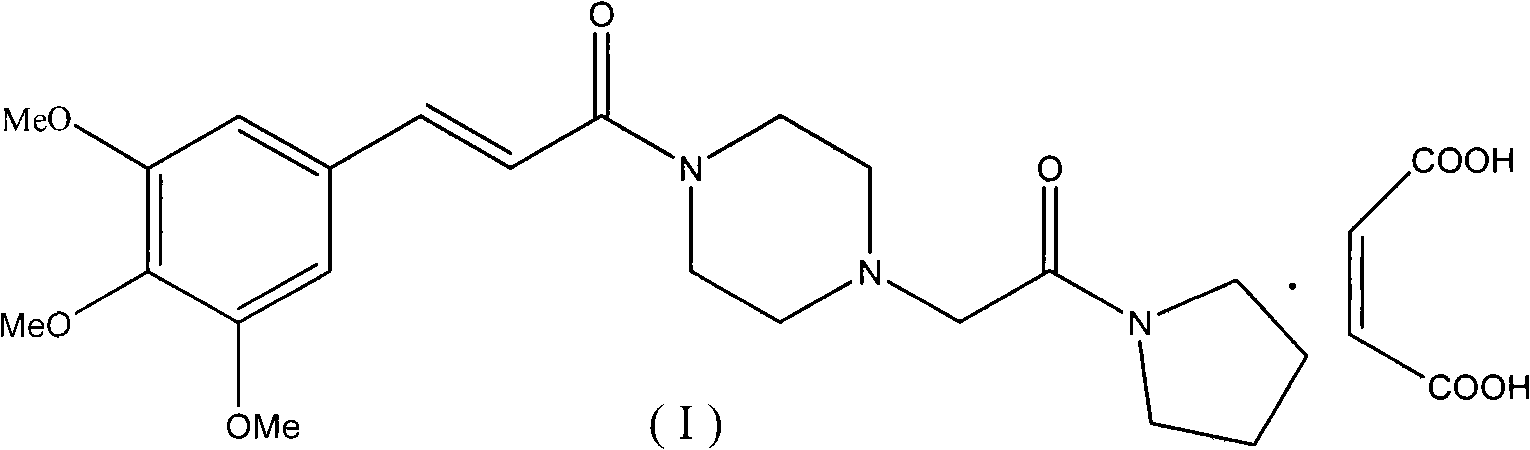

Preparation method of cinepazide maleate

A technology of piperazine and hydrochloride, which is applied in the field of preparation of pharmaceutical compounds, can solve the problems of large quantities, difficulties in extraction and crystallization of compound III, and achieve the effects of simple operation process, good crystal form, and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

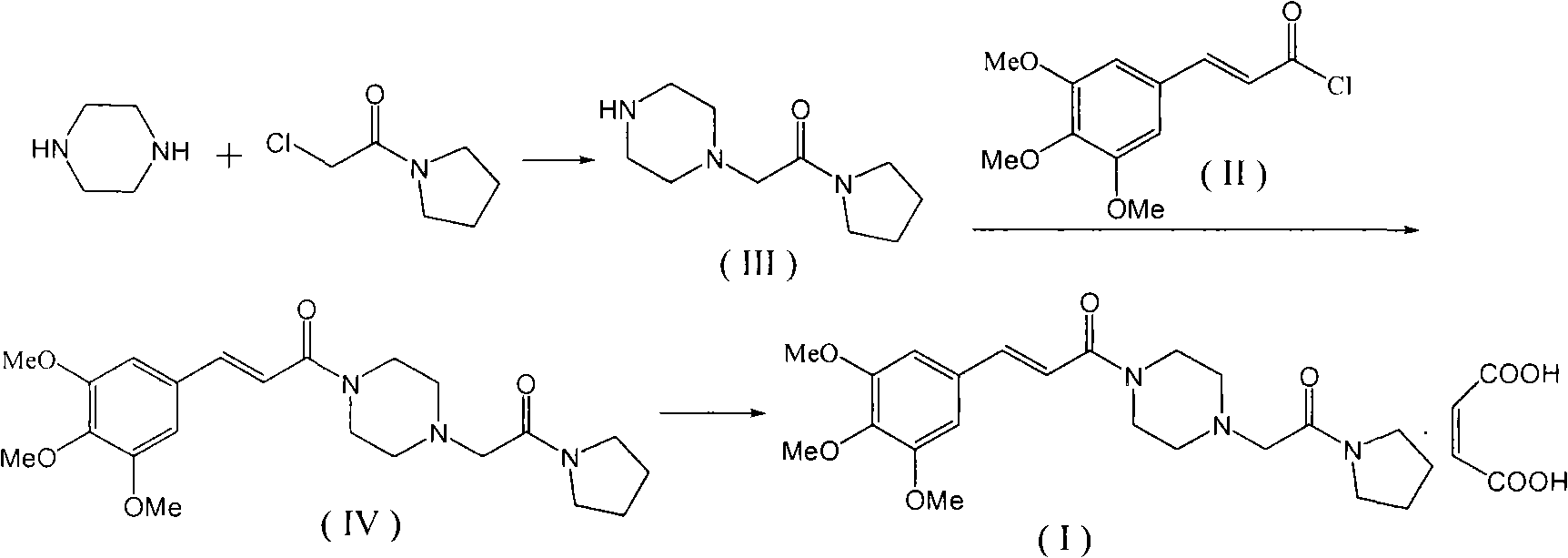

Method used

Image

Examples

Embodiment 1

[0036] 1.1. Preparation of chloroacetylpyrrolidine

[0037] 22.6g (0.2moL) of chloroacetyl chloride was added to 70mL of dichloromethane, cooled to -10°C; under stirring, 14.21g (0.2moL) of tetrahydropyrrole, 22.26g (0.22moL) of triethylamine in 20mL of dichloromethane were added dropwise. Chloromethane solution, the temperature is controlled below -5°C, and after the addition is completed, the reaction is continued at room temperature for 1 h. It was washed three times with 30 mL of water, dried over anhydrous sodium sulfate, filtered, concentrated to near dryness, and placed at room temperature to obtain 25.51 g of the product with a yield of 86.45%.

[0038] 1.2. Preparation of 1-[(1-pyrrolidinecarbonyl)methyl]piperazine dihydrochloride (V)

[0039] 31.8 g (0.2 mol) of piperazine dihydrochloride and 38.8 g (0.2 mol) of piperazine hexahydrate were added to 100 mL of absolute ethanol, and heated to reflux until completely dissolved. Under stirring, a solution of 29.51 g (0....

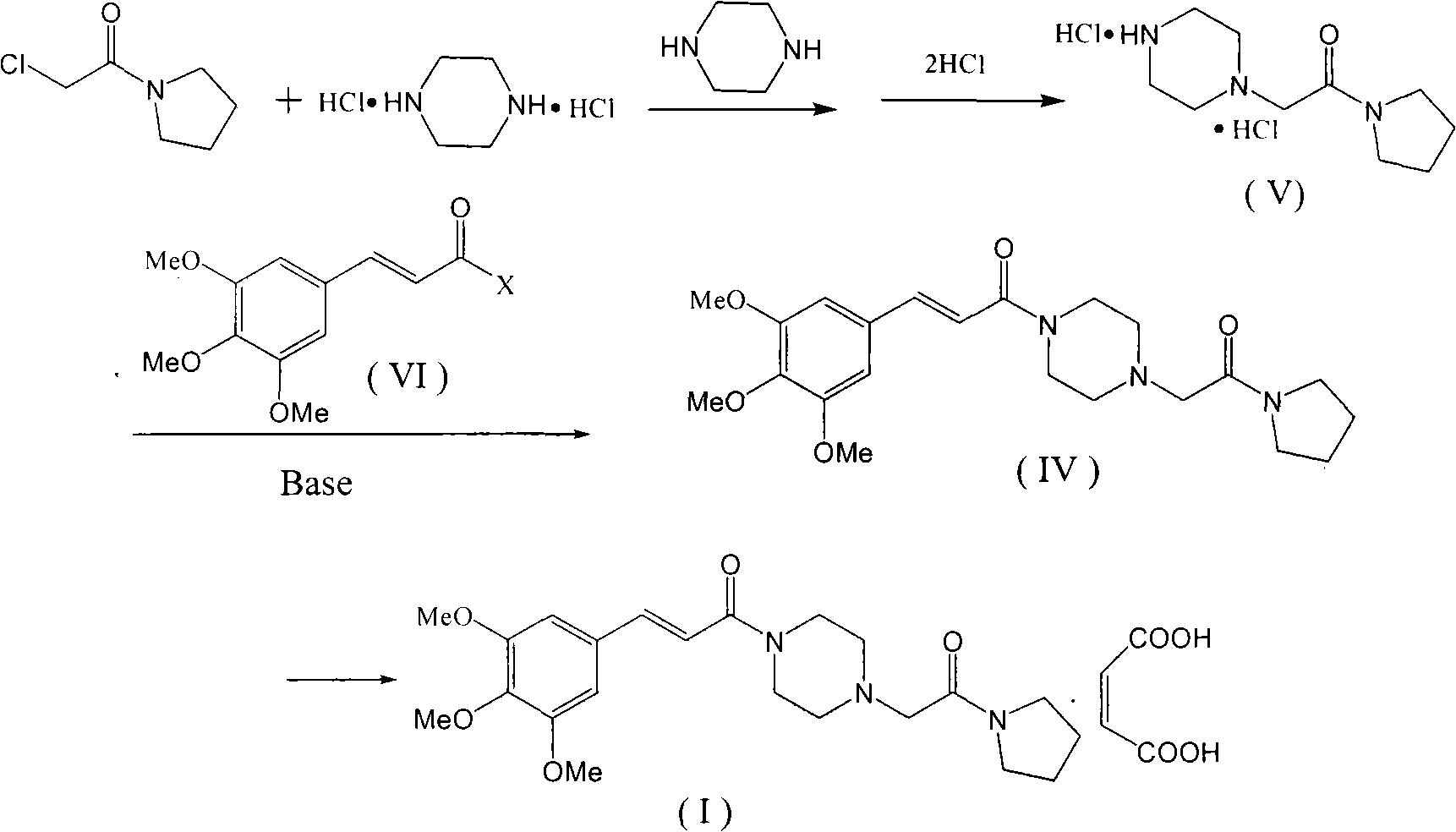

Embodiment 2

[0051] 2.1, the preparation of 3,4,5-trimethoxycinnamic acid phosphoric anhydride

[0052] 7.14g (0.03mol) 3,4,5-trimethoxycinnamic acid was suspended in 70mL dichloromethane solution, stirred for 10min, and 9.12mL (0.066mol) triethylamine was added. The temperature was lowered to 10° C., and under stirring, 4.78 mL (0.033 mol) of diethyl chlorophosphate in 30 mL of dichloromethane solution was added dropwise within 0.5 h, and the stirring reaction was continued for 1 h after the drop was completed. spare. or dropwise

[0053] 2.2. Preparation of 1-[(1-pyrrolidinylcarbonyl)methyl]piperazine in dichloromethane solution

[0054] Suspend 8.1g (0.03moL) 1-[(1-pyrrolidinylcarbonyl)methyl]piperazine dihydrochloride in 20mL dichloromethane, add 10.1g (0.1mol) triethylamine, stir at room temperature for 1h, filter A solid came out; the solid was washed with 10 mL of dichloromethane and combined with the filtrate to give a solution of 1-[(1-pyrrolidinylcarbonyl)methyl]piperazine in ...

Embodiment 3

[0059] 3.1, the preparation of 3,4,5-trimethoxycinnamic acid sulfonic anhydride

[0060] 11.91g (0.05mol) of 3,4,5-trimethoxycinnamic acid was suspended in 10mL of ethyl acetate, and 7.6g of triethylamine was added dropwise with stirring to obtain a transparent solution; cooled to -10°C, 10.6g was added dropwise (0.06 mol) benzenesulfonyl chloride in 20 mL of ethyl acetate solution, stirred at 0°C for 2 h and at room temperature for 1 h; filtered to obtain crude 3,4,5-trimethoxycinnamic acid benzenesulfonic anhydride.

[0061] 3.2, the preparation of cinepazide maleate

[0062] 13.5g (0.05mol) 1-[(1-pyrrolidinecarbonyl)methyl]piperazine dihydrochloride (V) was suspended in 200mL dichloromethane, and 20.2g (0.2mol) triethylamine was added dropwise at room temperature , and continue to stir for 0.5h after the addition. Within 1 h, the crude 3,4,5-trimethoxycinnamic acid benzenesulfonic anhydride obtained in step 3.1 was added in three portions, and the reaction was stirred at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com